208 Rock Blasting

General Information

This section only covers the

basic concepts of rock blasting. The

topic is covered in more detail in the FHWA manual, Rock Blasting and Overbreak Control,

FHWA-HI-92-001. Many of the figures and specification concepts originated from

this manual. The manual is available on

the FHWA website:

http://www.fhwa.dot.gov/engineering/geotech/library_listing.cfm

There used to be a training

course from NHI for Rock Blasting and Overbreak Control, but unfortunately this course is no

longer available from NHI.

Rock Blasting Basics

Rock blasting consists of

drilling holes in the rock at depths, in diameters, and at spacing so that the ANFO, which is a mixture of Ammonium Nitrate (fertilizer)

and Fuel Oil (diesel fuel), can fracture the rock in a controlled manner. The rock must fracture enough to displace it

and break it down to the size of the intended use.

The specifications limit the

way blasting contractors can blast to ensure that rock or blast vibrations do

not harm people or adjacent property.

Blasting Free Body Diagram

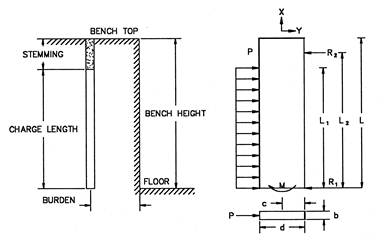

The basic geometry for rock

blasting is shown in Figure 208.A.

Figure

208.A – Rock Blasting Free Body Diagram

Holes are drilled to the

required depth in order to remove the rock and then filled with ANFO (the charge length).

The charge is topped off with stemming, which helps to hold the blast

down. The free body diagram on the

right-hand side of Figure 208.A shows the explosive pressure (P) and moment (M)

from the blast.

The blaster and blasting

consultant can arrange the geometry of the blast for optimal breakage. This is done so that P and M do not exceed

the amount needed to break the rock.

Excessive P and M causes flyrock and excessive

air blast and vibrations, which can cause damage and injury.

Blasting Geometry and Symbols

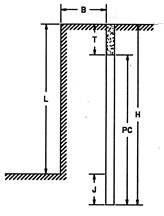

Figure 208.B further defines

the rock blasting geometry.

Figure

208.B – Rock Blasting Geometry and Symbols

Figure 208.B illustrates the

following blast geometry parameters:

§ B (Burden) is the distance between the free face and

the first hole.

§ T is the stemming (the inert material in the hole).

§ L is the length of the bench height.

§ H is the blasthole depth.

§ PC is the powder column length (ANFO).

§ J is the subdrill depth or

the depth the hole extends below the planned cut.

Two main parameters to

remember here are the L/B ratio and the stemming height.

Hole Spacing and Timing

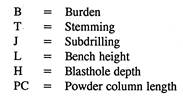

The top view of the rock

blasting geometry is shown in Figure 208.C.

Notice the distance B is still the distance to the free face. The distance S, or spacing of the holes, is a

function of the burden.

Figure

208.C – Rock Blasting (Top View)

The spacing of the holes and

the timing (or delay) of the holes are part of the blasting design. The bottom illustration in Figure 208.C shows

how the blast is delayed by the sequencing numbers. Each hole may be blasted milliseconds apart

to control the blast. The row-to-row

shots are certainly time delayed.

An initiation system

transfers the detonation signal from hole-to-hole at precise times. Plastic

shock tubes or electric caps using a timing system are generally employed. A shock tube is non-electric, instantaneous,

and has a thin reactive powder that propagates the shock wave signal.

The timing or delay minimizes

the pounds of explosive per delay period. This can significantly control noise

and vibration effects. It would be a

disaster if all the holes went off at the same time.

The design variables of

burden, stemming, subdrill length, spacing, and

timing are selected to maximize fragmentation and to minimize excessive

vibration, air blast, and flyrock.

Effects of L/B Ratio

Figure 208.D shows what happens

when the ratio between the distance L (bench height) and B (burden) is

changed. Potential blasting problems are

decreased as the ratio is increased. As

this ratio is decreased, these problems are increased.

|

Stiffness

Ratio (L/B) |

1 |

2 |

3 |

4 |

|

Fragmentation |

Poor |

Fair |

Good |

Excellent |

|

Air

Blast |

Severe |

Fair |

Good |

Excellent |

|

Flyrock |

Severe |

Fair |

Good |

Excellent |

|

Ground

Vibration |

Severe |

Fair |

Good |

Excellent |

|

Comments |

Severe

backbreak and toe problems. Do not shoot. REDESIGN! |

Redesign

if possible. |

Good

control and fragmentation |

No

increased benefit by increasing stiffness ratio above 4. |

Figure

208.D – Potential Problems as it Relates to Stiffness Ratio L/B

The specifications in 208.06.C

require that this ratio be greater than one.

The blasting contractor designs the correct timing, hole

spacing, and stemming. Historically, blasters in Ohio have not had problems

with designs having an L/B ratio near one.

Local blasters are very familiar with local geology as well.

Generally, a ratio near one

maximizes the rock blasting production.

The main problem with designing a ratio near one is that the rock

generally fractures in large chunks.

This can pose problems for the Contractors when trying to use the

material for fill. When the ratio is

increased, it can decrease the particle size of the rock. This allows the material to easily be used as

fill.

Proper Burden

In order to ensure that the

blaster is using the proper burden, follow this rule of thumb: the burden is

usually 24 to 30 times the production hole diameter. For example:

If the production holes have a

diameter of 6 inches (0.5 feet), then the burden should be:

24 × 0.5 ft

= 12 ft

or 30 × 0.5 ft = 15 ft

The burden for the shot

should be between 12 and 15 feet.

Effects of Stemming

The specifications in 208.06.E

require that the stemming depth (T) of inert material be at least 0.7 times the

burden (B). This helps control the air

blast.

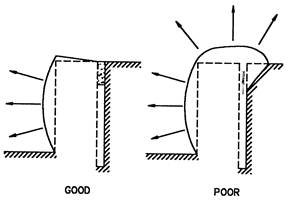

Figure 208.E depicts the

effects of stemming. If effective, the

blast direction is lateral. If the stemming is ineffective, the blast can

blow upward and cause excessive air blast. Notice in the poor example, the

blast cuts back into the cut slope. This

is an obvious problem.

Figure

208.E – Stemming Effects

Drill cuttings are normally

used for stemming. However, when

blasting in water-filled production holes or when blasting within 200 feet of a

structure, the stemming material is changed to prevent problems. For holes less than 4 inches in diameter,

crushed No. 8 stone is required. For

holes 4 inches in diameter or larger, No. 57 stone is required. This helps to hold the blast down better.

Effects of Timing

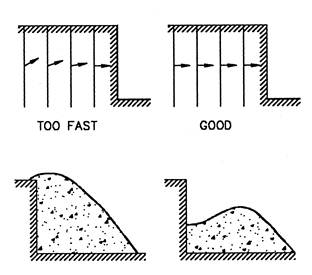

Timing of the blast is

another important parameter. Figure

208.F depicts the effects of poor and good timing.

With correct timing, the blast

has a distinct lateral movement. With

poor timing, the movement is more upright and has potential problems.

Vibration and Air Blast Monitoring (208.15 and 208.16)

The blaster is required to

design the burden, stemming, subdrill length,

spacing, and timing to minimize excessive vibration, air blast, and flyrock. The blaster

must monitor the air blast and vibration for every shot at the nearest

structure. Seismographs are used to

monitor the vibration.

Specialized equipment is used

to monitor the air blast. The maximum

air blast, in 208.16.A,

is required to be under 134 dB. The air blast limit may need to be lower in order

to prevent damage.

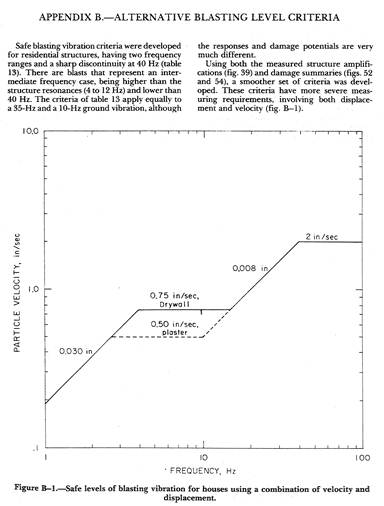

The specification does not

give vibration limits for blasting. Since each site is different, and the

blasting contractor is responsible for all damage caused by the blast, the

blaster hires a vibration specialist to determine the safe vibration limits. A

typical vibration criterion is given in Figure 208.G. This is from the US Bureau of Mines, RI

8507, Structure Response and Damage Produced by Ground Vibrations from Surface

Blasting, 1980.

To lower the air blast, check

the stemming height and type of material used for the stemming. Thin or thick areas of the burden may create

excess air blast and flyrock. Measure the burden to the free face to ensure

a uniform burden.

To lower the vibration

everything needs to be checked. This includes

the blast design and layout of the blast holes.

Figure

208.G – Typical Vibration Blasting Criteria

Each blast has a particle

velocity and frequency. The project can

plot these values on the chart in Figure 208.G.

If the point is lower than the plotted line, the blast is within limits

that are generally considered to be safe.

Presplitting (208.09)

Presplitting is a very

effective method of controlling the final appearance of steep slopes; it can

result in a clean sheared face.

Presplitting is required when the slope is steeper than 1H:1V and deeper than 5 feet.

Specialized presplit blasting

explosives are used. Hole

diameters are approximately 3 inches, and the presplit holes are blasted prior

to the production blast. The presplit hole spacing starts at 36 inches. This is adjusted to obtain a good, shear face

of the rock.

Documentation Requirements - 208 Rock Blasting

1. Accept pre-blast survey.

2. Verify the experience of the blasting specialists.

3. Accept and verify the blasting plan.

4. Ensure that the CA-EW-10

Item 208 Blasting Drilling Log is prepared by the driller.

5. Review the blasting area for blasting plan dimensions

with the blasting consultant.

6. Control blasting is used on cut slopes steeper than

1:1 and deeper than 5 feet (1.5 m).

Techniques are outlined in Section 208.10.

7. Production blasting is used for widely spaced

production holes in the main excavation.

8. Review the regulations of explosives as outlined in

Section 107.09.

9. A blasting plan is required at least 2 weeks before

drilling begins.

10. Review the detailed blasting plan of test shots.

11. Document test sections and drilling patterns.

12. Document safety procedures as outlined in 208.08. Ensure that the CA-EW-11

Item 208 Rock Blasting Site Security Plan is prepared by the blaster.

13. Witness all shots.

Inspect all shots using the CA-EW-9

Item 208 Rock Blasting Field Inspection Form.

14. Check vibration, air blast, and flyrock

for all blasts.

15. Check monitoring wells with Hydrologist.

16. Check the presplit face and requirements.

17. Measure presplit areas.

18. Monitor blasting consultants’ hours.

19. Review contractor’s record keeping for explosives and

blasting logs.

20. Review monthly blasting report.

21. Document on the CA-EW-9,

CA-EW-10, CA-EW-11 and the CA-D-2.

Do not repeat information on other forms listed unless necessary.