631 Sign Lighting

and Electrical Signs

General (631.02)

Sign lighting is not necessary

for overhead guide signs when Type H or J reflective sheeting is used for the

reflective legends. Therefore, for new

installations, sign lighting will normally not be used.

Guidelines and design

information on sign lighting are addressed in TEM

Sections 212 and 240-7.

This section provides

additional information about what to look for when installing sign lighting.

1. Check certified shop drawings, catalog cuts, etc. for

luminaires, ballasts, switches, and enclosures.

2. Luminaires for mercury vapor sign lighting shall

comply with 731.01

and shall consist of a housing that contains a reflector, lamp socket, wiring,

and a door containing a glass lens or refractor, which meet the following

requirements:

a. The housing shall be adequately reinforced cast

aluminum with a natural finish or painted gray.

b. The reflector shall be highly reflective aluminum.

c. The lamp socket shall be a porcelain

shrouded mogul screw with lamp grips and a large center spring, which provides

firm contact with a lamp base.

d. The door shall be an aluminum frame cast with either a

natural finish or a formed extrusion with an anodized finish. The door shall be

hinged securely to the housing and be provided with a spring loaded latch.

Hinges shall be stainless steel and designed so that unintentional door

separation is impossible. Latches shall be stainless steel and are not to

require tools for opening.

e. A flexible, readily removable gasket shall be attached

to the housing or door so a waterproof seal is formed when the door is closed

and the gasket compressed. The glass lens shall be mounted within the door and

sealed with elastic cement or a gasket.

f. The glass lens shall be borosilicate or equivalent and

able to withstand hail or the thermal shock of freezing rain.

g. Drainage weep holes shall be provided in the housing

or the door depending upon the luminaire’s bottom or top position on a sign.

3. Mercury vapor lamp sizes shall be as specified.

Ballast type shall match the specified lamp wattage. Lamp watts and ANSI code

are shown in TEM

Table 297-11 and SCD

TC-31.21.

4. Sign lighting shall be controlled by a disconnect

switch within an enclosure. The switch shall be a two-pole minimum, single

throw, fused safety disconnect type rated at 600 volts and 30 amperes (C&MS

Item 631.06).

The fuse size shall be as specified. A solid neutral bar shall be provided.

5. The enclosure shall be weatherproof and lockable,

complying with NEMA standard Type 4 ICS 1-110.15.

Enclosure size shall be as specified (See SCD

TC-32.10).

6. Each enclosure shall be furnished with at least one

padlock. Padlocks shall have a corrosion resistant body and a corrosion proof

steel shackle. All padlocks for a project are to be keyed alike from an

appropriate master key number obtained by the Contractor from the maintaining

agency.

7. Sign service to the enclosure shall be in accordance

with the plans. Service wiring cable size shall be as specified, single

conductor rated at 600 volts and no less than Number 4 AWG

(631.04). Sign service underground from a pull box to a foundation mounted

support, or to a support mounted on a concrete median barrier, is shown on SCD

TC-32.10. Sign service from a direct drop is shown on SCD

TC-32.11.

8. Sign wiring from the disconnect to the luminaires

shall be the size specified, single conductor rated at 600 volts and no less

than Number 10 AWG (631.05).

The wiring shall be fully protected within enclosures, support interiors,

junction boxes, rigid or flexible conduit, and luminaire housings. Wiring shall

be continuous from the disconnect switch to a junction box mounted on the sign

support or overpass structure. The junction box shall permit disconnection of

wiring when a sign and its lighting equipment are removed as a unit. A junction

box shall be installed for each sign. Wiring shall be continuous from the

junction box to the first luminaire on a sign and continuous between additional

luminaires on the sign.

9. Luminaire ballast shall be located within the

luminaire (integral) or in a weatherproof housing attached to or beside the

luminaire (contiguous). Wiring to the ballast shall be continuous with

permitted disconnection at the sign support junction box (see paragraph 8).

10. The wiring routing for wired signs shall be as shown

on SCD

TC-31.21.

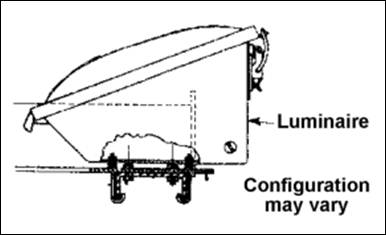

11. Luminaire supports complying with SCD

TC-31.21 are specified for new installations. Support arms are of welded

tubular design incorporating an attachment flange and a luminaire support

plate. The arms are bolted to a continuous rectangular galvanized steel tube

forming the lower portion of the sign’s glare shield. The face of the

rectangular tube shall be covered with non-reflective sheeting, which complies

with 730.20,

so as to match the color of the glare shield sheeting. Support arms shall not

be mounted upside down or in any other manner than that permitted by the SCD.

12. Luminaires shall be adjusted to a proper aiming angle

according to the manufacturer’s instructions and inspected at night to

determine if they are providing uniform illumination to the sign face.

Inspection

and Testing (631.11)

1. In accordance with 631.11,

sign lighting and electrical signs shall meet the requirements of the following

tests as required by 625.19

and performed by the Contractor:

a. Ground rod resistance to ground (see 632).

b. Cable insulation (Megger)

test (see 632).

c. Ten-day performance test (see 632).

2. During the 10-day performance test, failure of lamps,

ballasts, and transformers may be corrected by replacement of the faulty

component, but will not require restart of the entire test period.

3. The Contractor should perform a circuit test on all

sign lighting cable and wire conductors to determine if there are any short

circuits, cross circuits, or other improper connections. Circuit testing may be

done in accordance with 632.

4. The test results shall be reported to the Project

Engineer in the test information required by 625.19.

The test results should be documented.

5. During the 10 day performance test, a night inspection

shall be performed by the Contractor and final adjustments made to sign lateral

positions and the aiming angle of luminaires to the satisfaction of the Project

Engineer (631.11).

The adjustments are to eliminate excessive brightness and glare and to obtain

optimum sign face reflected brightness, uniformity of illumination, visibility,

and legibility.

6. Following successful completion of a 10-day

performance test and after there has been a partial or final acceptance of the

project, the Contractor should turn over to the Project Engineer all manuals,

diagrams, instructions, guarantees, and related material. The Project Engineer

should transfer the material to the maintaining agency. For ODOT maintained

signs, the material should be given to the appropriate ODOT District Office.

7. After the project has been accepted by ODOT, the

Project Engineer should immediately notify the maintaining agency that as of a

certain exact time and date, the agency is responsible for the maintenance.

Documentation

Requirements – 631 Sign Lighting

and Electrical Signs

1. Ensure signs and supports are in compliance with plans

and approved catalog sheets.

2. Document depth, diameter, or foundations.

3. Document steel and clearance maintained (if used).

4. Document support stubs (if placed).

5. Document anchors: diameter and depth (if used).

6. Document size and depth driven of drive post used.

7. Document curing used on concrete.

8. Measure appropriate units for foundations and/or

supports used and turn in for pay.

9. Document type, size, background sheeting, and legend

sheeting for signs.

10. Measure signs and turn in for pay as per 630.14.