SS-840 Mechanically

Stabilized Earth (MSE) Walls

Be advised SS840 dated 4/19/2013

is included in its entirety at the end of this document for reference only; the

official version is available online.

Introduction

MSE walls have been constructed in the State of Ohio for

over 25 years. In previous years, there

were special provisions in the Contract that detailed the construction and

design requirements. In the old special

provisions, each wall supplier had a unique special provision. The supplemental specification (SS-840) combines all of the

special provisions into one document.

SS-840

is updated frequently. Check the plans

and addenda to see which version is included in the Contract. If a more recent version is available,

consider adopting the new version by a change order. There may be a cost or savings involved with

adopting the new version, depending on what has changed.

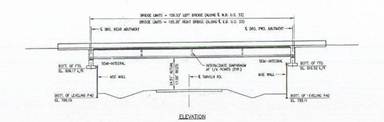

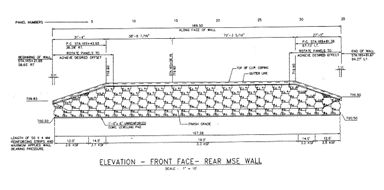

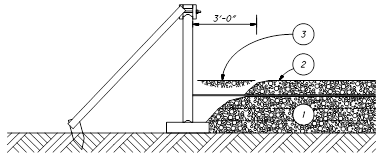

Below is a detail of a

typical MSE wall application. This is an elevation view of a MSE wall and bridge.

Figure

840.01.A MSE Wall Elevation View

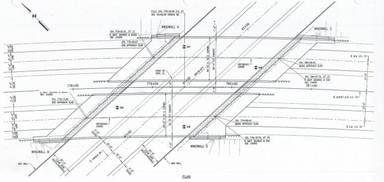

For the same bridge, a plan

view is shown below.

Figure

840.01.B Plan View of the MSE Wall and

Bridge

MSE wall specifications are

different than the normal construction specifications. There are both design and construction

criteria in the specifications. The

plans will detail a three line diagram of the MSE wall structure. The internal details and the construction

shop drawings are submitted after the sale of the project.

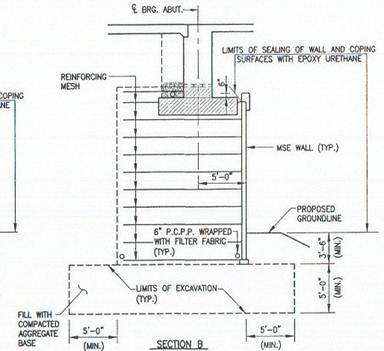

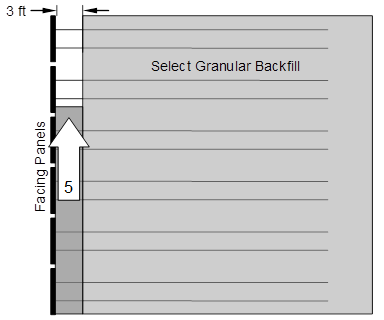

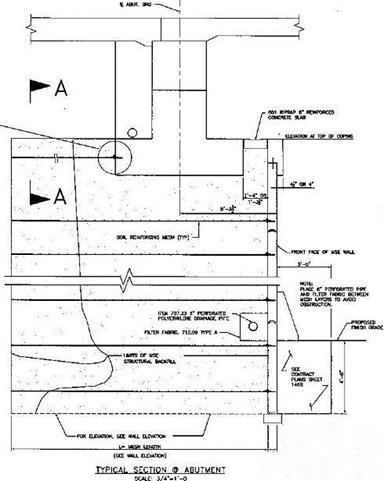

This detail shows the

reinforcing mesh in general form and the undercut.

Figure

840.01.C Typical Plan Cross-Section of a

MSE Wall

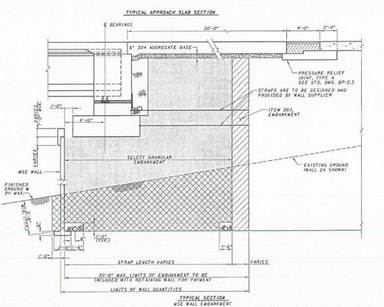

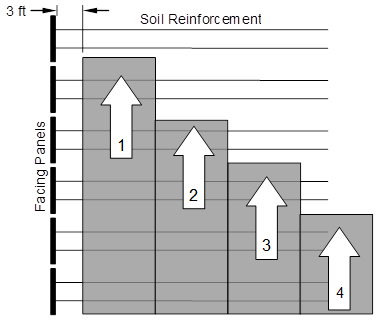

In the detail below, the

Designer has laid out the select granular backfill and 203

embankment.

Figure

840.01.D Layout of the Select Granular

Backfill and 203 Embankment

There are applications where

the Designer may choose to place a wall on both sides of an embankment as

detailed below.

Figure

840.01.E MSE Walls on Both Sides

General

Information

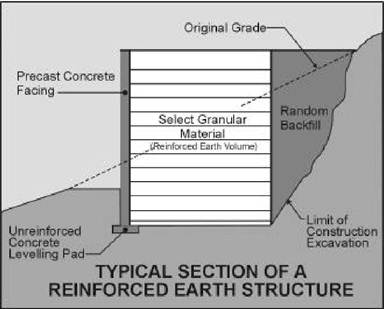

The following figure details

the general configuration of the MSE wall system.

Figure

840.01.F Typical Section of an MSE Wall

Structure

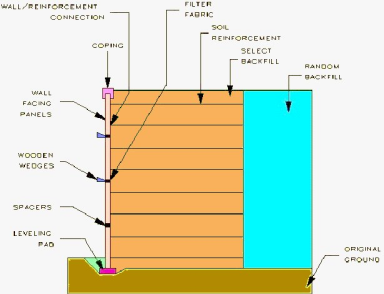

Terms

The following are standard

terms that will be used throughout this text.

Coping: The coping

is used to tie in the top of the wall panels and to provide a pleasing finish

to the wall top. It is cast in place.

Filter Fabric:

A geotextile filter fabric is used to cover the joint between panels. It is placed on the backside of the panel

joints. This keeps the soil from piping

through the joints and allows excess water to flow out.

Concrete Leveling Pad: The leveling pad is unreinforced cast-in-place

concrete. The concrete is 24 inches

wide, 6 inches thick, and has a minimum compressive strength of 2,500 psi. Cure the cast-in-place concrete for a minimum

of 12 hours prior to placing the first row of facing panels.

Original Ground:

The existing ground surface at the site.

Random Backfill:

Random backfill is the backfill that is allowed in normal embankment

construction.

Select Granular Backfill: Select granular backfill is the granular backfill

that meets the gradation, corrosion, unit weight, internal friction angle, and

any other requirements.

Soil Reinforcement: Soil reinforcement holds the wall facing panels in position and

provides reinforcement for the soil. The

soil reinforcement can be strips, grids, or mesh. The reinforcement can be made

of steel (inextensible materials) or polymers (extensible materials).

Spacers:

Wall panel spacers are typically ribbed elastomeric or polymeric pads. They are inserted between panels to help

provide the proper spacing. Proper

spacing keeps the panels from having point contact and spalling the concrete.

Wall Facing Panel: Wall Facing panels or panels are used to hold the soil in position at

the face of the wall. The panels are

made of precast concrete.

Wall/Reinforcement Connection: This is where the connection is made between the

wall facing panel and the soil reinforcing.

Wood Clamps:

Wood clamps are pieces of wood with a steel bolt. It is used to hold the panel in place once

the panel is set. The panel is not

released from the crane until the wood clams are in place and tight.

Wooden Spacers:

Wooden spacers are used to space the panels at the 3/4 inch-vertical

spacing. The spacer is held between the

panels to ensure the joints are not too close or far away.

The wooden wedges should be

made from any hard wood.

Wooden Wedges:

Wooden wedges are used to help hold the panels at the correct batter during the

filling operation. The wooden wedges

should be made from hard wood, such as oak, maple, or ash.

Figure

840.01.G MSE Wall Parts

Construction (840.06)

The wall system consists of

the original ground, concrete leveling pad, wall facing panels, coping, soil

reinforcement, select backfill, and any loads and surcharges. All of these items have an effect on the

performance of the MSE wall and are taken into account in the stability

analysis. A change in any of these items could have a detrimental effect on the

wall. The construction sequence follows:

Wall Excavation (840.06.C)

There are many instances that

the MSE wall is constructed in a cut section.

This means that the excavation behind the wall needs to be supported

temporarily in order to construct the wall.

A pay item for cofferdams and excavation bracing will be included in all

MSE wall plans, but if it is missing, the specification states that the cost

for cofferdams and excavation bracing are included with the MSE wall pay

item. The Contractor is responsible for

supporting the wall excavation. All work

to support the excavation or to fill the void behind the wall will be the

responsibility of the Contractor.

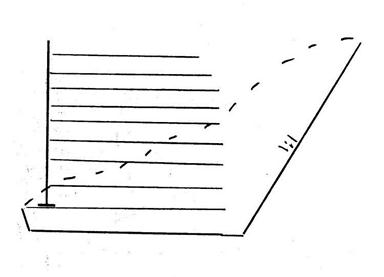

Figure

840.06.C.1 Excavation and Select

Granular Backfill Areas

Figure 840.06.C.1 shows the

wall excavation and embankment areas.

All of the area below the dotted line is paid for under wall

excavation. All the area in the

reinforced zone is filled with select granular backfill. The area below the leveling pad is filled

with undercut material. Below is a field

view of the same situation.

Figure

840.06.C.2 Area Behind the Wall

Foundation Preparation (840.06.D)

Preparation and Compaction

The MSE wall footprint area

needs to be prepared in the leveling pad, soil reinforcement, and select

granular backfill areas.

Figure

840.06.D.1 Foundation Preparation

Figure 840.06.D.1 above shows

a track hoe excavating down to the MSE wall foundation. All organic matter, vegetation, slide debris,

and other unstable materials, detailed as unsuitable in 703.16,

needs to be removed. Once the unsuitable

soil is removed, 1 foot outside of the foot print formed by the leveling pad

and soil reinforcement needs to be compacted.

The foundation needs to be compacted to meet the requirements of 203.07. If the foundation material is granular then

the material needs to be compacted by one of the test section methods detailed

in S-1015.

Once the foundation is

compacted, then the foundation for the wall needs to be graded level for the

full-length and width of the leveling pad and the soil reinforcement.

Foundation Evaluation

Once the foundation is

compacted, the Department needs to evaluate the foundation. Contact the District Geotechnical Engineer or

the plan design soils consultant to evaluate the foundation. This can be paid for through continuing

services during construction through the project design coordinator. The DGE or soils consultant will evaluate the

soil conditions. In the design phase, a

bearing capacity and stability analysis was performed for the MSE wall based on

the plan borings. This needs to be

reevaluated based on the existing soil conditions during construction. The DGE or soils consultant will make a field

visit to the site to determine if the foundation soils found during

construction meet the soil conditions designed for in the plans. They will then report to the Department to

give their results. The Contractor’s pay

depends on receiving this report so the Contractor will prompt the Department

to make this evaluation.

The project should review the

soils’ consultant report. The project

should ensure that the excavated soils match the soil borings performed to

design the wall. If the existing

conditions do not match plan soil borings or there are any unusual problems

with the report, contact the State Construction Geotechnical Engineer.

Undercut and Drainage

Drainage and the foundation

conditions are important parameters of the MSE wall system. Therefore, many contracts will detail an

undercut. If an undercut is in the

plans, the foundation work detailed above should be performed on the foundation

of the undercut.

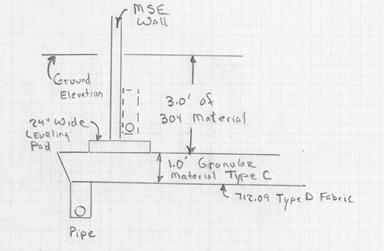

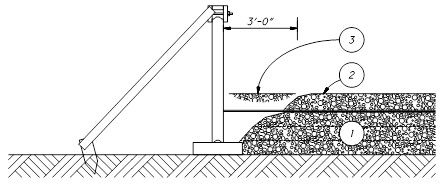

The following sketch details

a standard undercut.

Figure

840.06.D.2 Standard Foundation Undercut

Once the foundation of the

undercut is compacted, the drainage pipe is constructed. The plans will detail the pipe with a pay

item. The pipe must be outletted. There will be at least 50 feet of outlet pipe

in the plans to outlet the pipe. The

project will have to look for an outlet if it is not detailed in the

plans. Pipe, manholes, and other items

can be used as a drainage outlet.

If the pipe cannot be

drained, move the pipe to the outside of the wall until it can be drained. The dotted pipe above the leveling pad, in

Figure 840.06.D.2, represents this pipe.

It is shown on the inside of the wall, but there is no need to put the

drain on the inside of the wall. It can

also go on the outside of the wall. The

sand on the inside is free draining.

Figure 840.06.D.3 below shows

a 5 foot undercut operation. The

replacement material in this case was a well graded blast rock. The material of choice for foundation

replacement should be Item 203,

Granular Material Type C. The upper

portion should be chocked off with at least 1 foot of Item 203, Granular

Material Type B. Geotextile Fabric Type

D should be placed below the Granular Material Type C. This will prevent the piping of fines from

the top and the bottom of the Granular Material Type C.

Figure

840.06.D.3 Replacing the Foundation

Leveling Pad Construction (840.06.E)

Once the foundation is

compacted and prepared, a 2-foot wide and 6-inch thick un-reinforced concrete

pad is constructed. The purpose of this

pad is to serve as a guide for the wall panel erection. This leveling pad is not intended to provide

significant structural foundation support in the final configuration of the

wall, but there is significant construction panel loading on the leveling

pad. Therefore, it must be properly

constructed and on a firm foundation in order to minimize potential wall

movements during the construction of the wall.

Figure

840.06.E.1 Leveling Pad Construction

The leveling pad is important

to the construction of the wall, because the leveling pad sets the horizontal

and vertical alignment of the wall. It must

be in the correct horizontal position, level, and at the correct grade.

Figure

840.06.E.2 Accurate Leveling Pad

Construction is Important

If the final wall is not

level, the panels will bind against each other causing spalling of the edges

and corners. If the wall is not started

correctly, the finished product is seldom satisfactory.

No more than 2 shims (each

3/16 inch thick) should be required to level the panels on the leveling

pad. If level cannot be obtained with

two shims, then the leveling pad and the bottom of the panels needs to be

checked.

Figure

840.06.E.3 Improper Shimming

Under no circumstances are

bearing pads allowed on the leveling pad.

Bearing pads can create point loads on the panels and allow for movement

of the panels during construction.

Figure

840.06.E.4 Bearing Pads are Not Allowed

on the Leveling Pad

Care must be taken to ensure

the leaving pad is correctly aligned.

The leveling pad is 24 inches wide to allow for some alignment errors

and inconsistencies, for example, when going around corners and curves. In addition, the wider leveling pad will

supply more support during construction.

Do not allow any overhanging

of the panels off the leveling pad. If

this happens, stop the construction and investigate the problem. If needed, reconstruct the leveling pad.

Figure

840.06.E.5 Improper Overhang

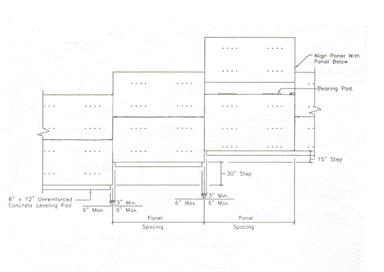

Leveling pads that change in

elevation have special challenges in design and construction. Figure 840.06.E.6 below details this

challenge. This figure is a general

step-up figure with some of the dimensions changing in the new SS-840.

Figure

840.06.E.6 Change in Leveling Pad

Elevation

The challenge is to arrange

the leveling pad and panels so that when this elevation change occurs, the panel

is almost fully supported by the leveling pads.

Multiple elevation changes are even more difficult to construct. In all cases, a 6-inch maximum overhang along

the wall is allowed. The minimum

overhang distance along the wall is approximately 3 inches.

Figure

840.06.E.7 Acceptable if Less than 6

inch Overhang

The concrete leveling pad

must cure for at least 12 hours before wall panels can be placed.

Figure

840.06.E.8 Finished Concrete Leveling

Pad

Wall Panels Types and Parts (840.04.A)

Wall panels come in many

shapes and sizes. The most common are

the square and rectangular. They can be

custom built into any configuration that will fit together. The front face can have any type of finish,

shape, texture, or other surface treatments that can be formed.

Figure

840.04.A Reinforced Earth Panels

Figure

840.04.B Rectangular Panels

Figure

840.04.C Textured Finish Panels

Corner Panels

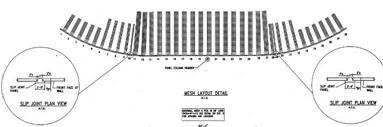

Corner panels provide a good

connection between the two walls and act like slip joints for the wall allowing

differential movement between the two walls.

Slip Joints

Typically a slip joint is

used to handle large differential vertical movement of the wall. There are two in the figure below, one on

each side of the corner section.

Figure

840.04.E Corner (front) and Slip Joints

(One on Each Side)

Handling, Storing and Shipping Panels (840.05.H)

Panels should be stored flat

and on spacers or dunnage. Spacers are

typically sent by supplier on pallets of panels. Spacers protect the galvanized soil

reinforcement connections from being bent or damaged by other panels. Panel faces should be kept away from areas

that are muddy to prevent staining of the face of the panel. The project should ensure that panels don’t

have spalling or cracking upon delivery to the site.

Correct storage is shown in

Figure 840.05.A. Note that the dunnage

height is more than the soil reinforcement connections to minimize damage.

Figure

840.05.A Proper Panel Storage with

Dunnage

Figure 840.05.B is an example

of improperly stored panels. The panels

in this case can get chipped or cracked.

Figure

840.05.B Improper Panel Storage

The soil reinforcement

connections also can get bent.

Panel Inspection

Panel Dimensions and Tolerances (840.05.G)

When the panels first arrive

at the project, the panel documentation needs to be checked. The panels come with a TE-24. The documentation required with this TE-24 is

a record of final inspection of all precast components and the measurements of

the tolerances, strength, and dimensions of all panels. As one final check, the dimensions need to be

randomly checked at the project. The

shipment paperwork, shop drawings, and the actual panel dimensions need to be

compared to ensure that issues are found in a timely manner. The earlier in the process that these

problems are found, the easier it will be to correct the issues. Some of the panel items to pay particular

attention to are:

1. Length, width, and thickness.

2. Squareness.

3. Finish.

Physical measurements of the

panels are required. The project should

use a tape and carpenters square to check the above. All of these dimensions have an effect on the

Contractor’s ability to construct the wall within the specification tolerances.

Figure

840.05.D Checking the Squareness of the

Panel

Precast Panel Rejection (840.05.J)

Damage to the Galvanized Soil

Reinforcement Connections

If the soil reinforcement

connections are damaged to the point that it inhibits the soil reinforcement from

being attached, then the panel needs to be rejected. Many times the connection is filled with

residual cement or concrete that does not allow the soil reinforcement to be

connected. If this is the case, have the

Contractor clean out the connections. Do

not cut the soil reinforcements.

If the connections are bent

more than 15 degrees from perpendicular, the panel needs to be rejected. When bent beyond 15 degrees, the galvanizing

is compromised and cannot be repaired.

Damage to the Panels

The panels also need to be

inspected for damage. Panels can be

damaged almost anywhere during the manufacturing or construction process. Many of the chips and cracks are caused by

poor handling. Chips or spalls can be

prevented by using nylon straps in the handling process. Cracks can be avoided by taking care in the

handling process. There is a list of

defects and damages in 840.05.H that are sufficient

reason for rejecting a panel. Depending

on the severity of the damage, the Contractor may propose a repair.

Figure

840.05.E Rejected Cracked Panel

Figure

840.05.F Rejected Lifting Spall

Figure

840.05.G Repairable Lifting Strap

Spalling

Figure

840.05.H Repairable Handling Spalls

Wall Erection (840.06.G)

Panel Identification

At this point, we have

constructed the foundation, added drainage, checked the materials, and

constructed the leveling pad.

There is one last step we

need to perform before we construct the wall; the wall and shop drawings must

be checked to ensure that the correct panels are being used in the correct

location along the wall. Depending on

the wall height, the panel shape, or design, the number of soil reinforcement

connections on the back of the panel may vary.

The panels with the most connections will typically be in the lower

panels of the wall. In the upper

portions of the wall, the number of connections may be less. It is important that the panels are used in

their proper position. Below is a

typical shop drawing showing the panel organization.

Figure

840.06.G.1 Typical Panel Erection Shop

Drawing

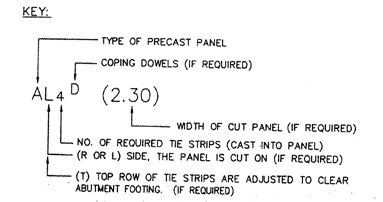

The erection drawings have a

numerical code on each panel that depicts its position in the wall. In the above shop drawing, the letter A denotes full-height panels in the

first row and the subsequent rows until the shape changes as the panel is just

below the coping. The letter B denotes half-height panels in the

first row. The codes HX, F11, L11, KX,

K, E, EX, HJJ, KJJ, LJJ, DJJ, and EJJ denote panels just below the coping. Note

the combination of letters. R or L will be used to denote the right or

left side of the wall. A number that

follows the letters denotes the number of tie strips required for the

panels. Below is a code that details the

panel letter and numerical system.

Figure

840.06.G.2 Code for Panel Placement

(Reinforced Earth)

The code that is detailed

above is for Reinforced Earth walls. The

code for other wall systems will be different, and the code for a particular

wall system may change at any time. The

codes are marked on the back of the panels for easy reference during

construction. Below is a photo of the

marking on the back of a panel.

Figure

840.06.G.3 Actual Panel Markings

The above markings show piece

A has 3 tie strips and is on the right side of the wall. Other required markings include date of

manufacturing, production lot number, and the precaster’s and accredited

manufacturer’s inspection and acceptance marks.

Placing the Panels

Picking up the panels is an

important aspect of the construction procedure.

If the panels are not properly picked up, spalling or cracking can

occur. The figure below shows the

correct method of picking up the panels.

The crane lifts the panel so that no concrete to concrete contact

occurs.

Figure

840.06.G.4 Picking up the Panels

The correct placement of the

first row or two of panels is very important.

When the panel construction is not started correctly, the finished product

is rarely satisfactory.

In the figure below, a chalk

line is placed on the leveling pad to properly align the panels along the

leveling pad. Sometimes a 2×4 is used to

align the panels. Adjust the alignment

using a crowbar as shown below. At this

point, the panel is still supported by the crane.

Figure

840.06.G.5 Proper Placement

As one last check of the

horizontal alignment, the panel to panel horizontal offset needs to be checked.

Use a straightedge across the panel horizontal joints to ensure that the panel

to panel horizontal offset does not exceed 1/2 inch.

The first row may be composed

of both half- and full-height panels. A

photo of full- and half-height panels is shown below. The panels need to be in proper alignment and

level.

Figure

840.06.G.6 Half Height Panels

Horizontal Leveling

Once the panel is placed on

the leveling pad, the panel needs to be leveled horizontally. A 6-foot level rod is placed on the top

surface of the panel to determine if it is level.

Figure

840.06.G.7 Proper Horizontal Leveling

If it is not, shims are

placed under the panel in order to make the panel level. Galvanized metal washers or rubber shims are

allowed. A maximum 3/8 inch in total

shim height, at any location, is allowed.

If more shims are required, then the leveling pad is not level or the

panel bottoms are not flat. In either

case, the issue is the Contractor’s responsibility to resolve.

Figure

840.06.G.8 Metal Shims to Level the

Panels

Horizontal Joint Spacing

Without the correct joint

spacing, panel corners will crack and spall with the wall settlement. Spacing blocks must be used. As the panels are placed together, the

3/4-inch spacers are placed in the joints.

The panels are maneuvered so that there is contact between both panels

and the joint spacer. The required joint

spacing is 3/4 inch ± 1/4 inch. If this

spacing cannot be achieved, the Contractor is required to submit an action plan

to correct the problem. The spacer is

shown in the figure below. If the panel

is moved during the joint spacing adjustment, then the horizontal leveling

should be checked again.

Leave the horizontal spacers

in until half of the panel height is filled with backfill.

Figure

840.06.G.9 Wooden Joint Spacers

Vertical Alignment

The panels need to be set

with a backward batter toward the inside of the wall. The typical batter is about 1/8 inch per foot

of panel height or about 1/2 to 1 inch per panel. Compacting the backfill behind the wall

pushes the panel outward, so the panel will be vertical once the fill is placed

against it. The amount of batter is

adjusted for the site conditions, such as backfill properties; the finer sand

may require a more batter. If a fine

graded material, such as foundry sand is used, then it may require a 1-inch

batter. A well-graded, crushed limestone

may require a 1/2-inch batter.

Figure

840.06.G.10 Batter Check

A level with a batter spacer

is placed on the outside or inside of the wall.

Use the outside of the wall unless textured. The batter spacer can be used on the top or

bottom of the level. If the level is

used on the outside of the wall, the batter spacer is used on the top of the

level. If the level is used on the

inside of the wall, the spacer is used on the bottom of the level. The spacer is usually duct taped on to the

level at a thickness of the batter. In

the figure below, it shows the batter spacer being used on the inside of the

wall.

Figure

840.06.G.11 Vertical Leveling Spacer on

the Inside of the Wall

The level can also be used on

the outside of the wall as shown below.

Figure

840.06.G.12 Vertical Batter on the

Outside of the Wall

Vertical and horizontal

alignments and joint spacing needs to be checked one last time prior to

temporarily locking the panel in place.

For the entire time the horizontal leveling, joint spacing and vertical

alignment is being adjusted, the panel is still suspended from the crane so

that the panel is not damaged.

Triangular Wedges and Wood Blocks

Wooden triangular wedges are

used to lock the panel into vertical alignment once the wall is battered with

the level. The wedges are shown below on

the leveling pad.

Figure

840.06.G.13 Wooden Wedges for Vertical

Alignment

No more than three levels or

rows of the wooden wedges should be placed in the wall without removing the

lower row. If more than three levels of

wedges are used they may become bound in the wall making them very difficult to

remove and can cause the panel to spall.

Wooden clamps are used to

hold the panels together. Wooden clamps

are two pieces of wood held together with a long bolt. The bolt is tightened to hold the panels

together.

Figure

840.06.G.14 Wooden Clamps

Triangular wedges are also

used in combination with the clamps to secure the panels as shown in the figure

below.

Figure

840.06.G.15 Triangular Wedges and Wooden

Clamps

External bracing is required

for the first row of panels to maintain stability and alignment. Typical bracing is shown below.

Figure

840.06.G.16 Proper Bracing

At this point, the geotextile

fabric and the select granular backfill are placed to the height of the wooden

clamps. These steps will be described in

detail later.

When panels are placed on one

another, a horizontal bearing pad is used to separate the panels. A minimum of two bearing pads are used. The horizontal joint should be 3/4 inch at

this point. Some Accredited Wall Systems

may supply thicker bearing pads. This is

anticipation of the bearing pads deflecting under the load of the wall. Check the accepted wall shop drawings to

ensure that the thicker pads are allowed.

Figure

840.06.G.17 Bearing Pads on the Second

Row

Subsequent panel rows are

placed between panels that were previously placed. The ability to properly

space and align these rows relies on the proper placement of the lower

rows. All of the error produced by the

lower rows is propagated upward and is difficult to correct. The same leveling, joint spacing, vertical,

and horizontal alignment applies to all the rows.

Figure

840.06.G.18 Panel Placement

Panel-to-panel vertical

offset needs to be checked as soon as the next row of panels is placed. Use a straightedge across the vertical joints

to ensure that the offset between panels is less than 1/2 inch.

Figure

840.06.G.19 Second Row of Panels Placed

The process starts all over

again as crow bars are used to align the next row of panels.

Figure

840.06.G.20 An Existing Joint Offset

Problem

Alignments need to be checked

periodically to ensure proper alignment.

This will ensure that problems are spotted early and corrections can be

made before the panels get too far out of alignment.

Figure

840.06.G.21 Wall Alignment

As stated before, the panels

are battered back so that the fill placement can move them forward into a

vertical position. After the fill is

placed, check the vertical position of the wall. After the third row of panels

is placed, use a plumb bob to check the vertical alignment. Hold the plumb bob at the top of the panel

and measure the out of plumbness, as shown below.

Figure

840.06.G.22 Checking Vertical Alignment

with a Plumb Bob

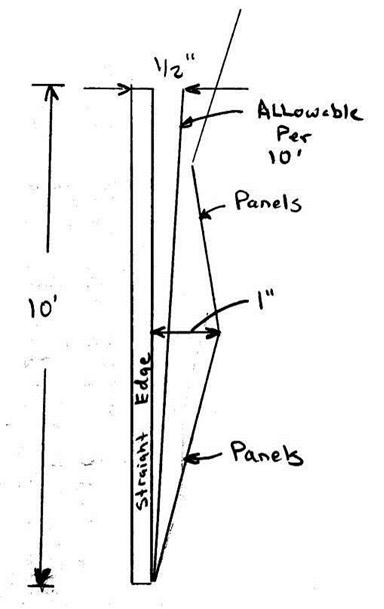

The tolerance is 1/2 inch in

10 feet. By using a 10-foot straightedge

and a level or a plumb bob, this tolerance can be measured. At no point along the straightedge can any

portion of the panel be more than 1 inch away from the string or straightedge.

Figure

840.06.G.23 Measure from the Wall to the

String (Out of Plumb Here)

A summary of the wall

erection tolerances are listed below:

1. Vertical Tolerance: 1/2 inch overall and 1 inch at any

point.

Use a 10-foot straightedge,

2. Horizontal Tolerance: 1/2 inch overall and 1/2 inch at

any point.

Use a 10-foot straightedge.

3. Panel to Panel Tolerance: 1/2 inch horizontal and

vertical.

Use a 6-foot straightedge.

Figure

840.06.G.24 Panel Tolerances

Filter Fabric Placement and

Inspection

Filter fabric is placed

across the joints so that the granular backfill does not leak through the

joints to the outside of the wall. The

minimum lap on each side of the joint is 1 foot on each side of the joint and 1

foot along any cut piece of fabric along the joint. These requirements apply to horizontal and

vertical joints.

The fabric is cut in lengths

to cover the horizontal and vertical joints.

Once the fabric is cut, the fabric is laid on a flat surface. An adhesive is used to hold the filter fabric

in place until the select granular backfill is placed over the joints. A thick bead of the adhesive, approximately

1/2 inch in diameter, is applied around the entire perimeter of the fabric,

about 2 inches from the edges of the fabric.

See the figure below.

Figure

840.06.G.25 Correct Application of the

Adhesive

Figure

840.06.G.26 Fabric Completely Covering

the Joints

Once adhesive is applied to

the fabric, it is immediately placed on the wall. Ensure that the fabric is placed on the wall

before the adhesive dries. The fabric needs to fully engage the wall at all

locations to ensure that the sand does not leak through the joints.

Figure

840.06.G.27 Wrong Application of the

Adhesive on the Wall

As shown above, randomly

placing adhesive on the wall does not ensure that the joint is properly

sealed. More adhesive is not necessarily

good. Correctly applied adhesive and the

appropriate placement of the fabric is the solution.

In the past, some projects

have only glued the top portion of the fabric applied to a horizontal

joint. This method should be

discontinued and not be allowed.

Figure

840.06.G.28 Partial Gluing (Do not Allow

this)

Small tears or wrinkles in

the fabric can cause leaking of the sand.

Any leaking of the sand through the joints is not tolerable. Leaking sand is like a leaky water pipe; it

never gets better with time, it only gets worse.

Once the fabric and the

backfill are placed, the project should go around to the front of the wall to

inspect the joint spacing and the fabric’s ability to hold the sand behind the

wall. Take a flashlight and inspect the

joints. Look to see if the fabric is in

place and holding the sand back.

Look for deposits of sand in

the horizontal and vertical joints, as shown below.

Figure

840.06.G.29 Sand in the Joints on the Outside of the Panels

Sand deposits may be caused

by sand falling over the wall during construction or the sand is leaking

through the joints. By carefully

inspecting the joints, the source of the sand deposit will be found. In the figure below, the sand is leaking out

of the joints and being deposited on the ground.

Figure

840.06.G.30 Sand Falling from Several

Joints

After further inspection of the

wall from behind, it was found that the fabric was not placed in the upper

portion of the MSE wall. This project

was about three-years-old at the time of the inspection. A thorough inspection during the construction

of the wall would have prevented this maintenance problem.

Figure

840.06.G.31 No Fabric Placed Behind the

Wall

Below is a photo of a wall,

which was taken shortly after construction.

As you can see, there are sand deposits at the bottom of the slip

joints. In this case, the fabric was

either not placed or improperly placed.

Figure

840.06.G.32 Sand Piles around Slip

Joints

In the figure below, looking

behind the wall at a typical slip joint during construction, you can see that

the fabric has to go around a bend.

Careful construction in this location is required. When placing fabric around corners or

obstructions, leave the fabric loose so that it does not tear during the

placement of the backfill in the corner.

Figure

840.06.G.33 Fabric Placement around a

Slip Joint

There are a lot of other

items of work that obstruct the proper placement of the fabric in this

situation. In the figure below, there

are the reinforcing steel, wooden clamps, and a settlement plate that the

fabric needs to go around. There is

ample opportunity for sand to leak around the fabric if we are not careful.

Figure

840.06.G.34 Obstructions near a Slip

Joint

The joint spacing needs to be

reexamined in the front of the wall. We have

previously checked and recorded the joint spacing when the panels were

constructed. There may be cases where

after the wall is constructed, the joint spacing is wider than the allowable

3/4 inch plus 1/4 of an inch.

Figure

840.06.G.35 Wide Joint and Exposed Fabric

The joint gap in the above

figure is almost 1-3/4 inch. The gap is

wider than the panel’s ship lap, therefore, exposing the fabric. The width of the ship lap is about 1-1/2

inches. In the above case, the

Contractor needs to be instructed to place expansive foam and caulk to the

joint to prevent the fabric being exposed to sunlight.

Sunlight can cause the fabric

to deteriorate with time, whether direct or indirect. A flashlight is used to minimize sunlight

exposure to the fabric. A flashlight is

held perpendicular to the joints, about 6 inches away from the joint. The described flashlight test is shown in the

figure below.

Figure

840.06.G.36 Flashlight Test

If the light from the

flashlight can be seen on the fabric, then the joint needs to be sealed. Expanding foam and caulk is used to cover the

fabric.

There have been instances where,

after the wall has been constructed, the fabric is destroyed during water

jetting operations. Water jetting is

used to clean the panels prior to sealing; therefore, examine the joints after

the sealing operation.

As a final note on the wall

construction, continue to monitor the wall throughout the duration of the

project. The wall is designed and constructed to tolerate movement. Too much movement is detrimental to the wall

and the structural items around the wall.

Select Granular Backfill Placement (840.06.I)

Material

The granular backfill

materials have special requirements that are not normally associated with

granular material in other items of work.

There are material requirements such as pH, resistivity, chloride, and

sulfate levels. These requirements

minimize the corrosion of the metal soil reinforcement. The project and district test lab need to

review and evaluate the test data for these requirements. Ensure that the test results meet the

specification requirements and that the correct tests were taken on the

materials. If the backfill material does

not meet these requirements, then there is a high probability that the metal

soil reinforcement will prematurely corrode and the life of the MSE wall will

be shortened.

Another requirement is the

internal angle of friction. The internal angle of friction is critical to the

design of the wall. The wall design and

the factor of safety are sensitive to numerical value of the friction angle. The factor of safety can change dramatically

with only a few degrees of friction angle change. The design friction angle is 34 degrees. The test ensures that the design assumption

is valid.

The specification allows the

use of granular material Type 2 which is old Item 310 material. It can be very fine sand or a coarse 304

type material. Since economics

drives the material choice, the vast majority of the time sand is used.

The specification also allows

the use of Item 304

material. This material is a well

graded and very stable material.

It is a requirement to use

the Item 304

material for the first 3 feet of backfill behind the wall. This is a stronger material and is more

resistant to the influences of water.

After the first 3 feet are placed, the sand or the 304

may be used.

Select Granular Backfill

Placement and Compaction

The below placement and

compaction procedures were developed to produce uniform compaction of the

select granular backfill (SGB). Uniform placement and compaction of this

material is essential in order to keep uniform pressure against the wall as it is

constructed. Unnecessary compaction or

non-uniform compaction of this material can create bulges in the wall or loose

areas in the backfill behind the wall.

This procedure is to be followed all the way to the top of the wall.

On the initial row of panels

(and only the initial row of panels) the backfill is not placed against the

panel until the first layer of soil reinforcement has been connected and the

initial layer of backfill is placed and compacted on top of the soil

reinforcement. This is to keep the

bottom of the panels from “kicking out.”

If the SGB cannot be compacted effectively below the first row of soil

reinforcement, because some manufacturers may have mesh that we cannot compact

through, then the wall supplier will need to design a kicker to prevent the

wall from kicking out at the bottom.

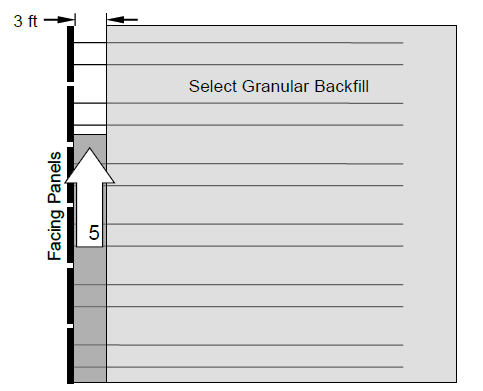

Figure

840.06.I.1 Backfilling for the First

Panel Only

Once the backfill is placed

and compacted to the elevation of the first layer of soil reinforcement as

shown in Figure 840.06.I.1, the soil reinforcement is connected. Then the next loose lift is placed on top of

the soil reinforcement 3 feet away from the wall. The material is then leveled by moving it

parallel to the wall and windrowing the material toward the soil reinforcement

ends and away from the wall. See Figure

840.06.I.2 for the spreading operation details.

This SGB material which is 3 feet away from the wall is then compacted

in the same way as it was placed.

Figure

840.06.I.2 Procedure for SGB Placement and Compaction

Once this is completed, the

void is filled and compacted next to the wall to the elevation of the soil

reinforcement. The material void left

above the soil reinforcement is then placed and compacted. Place and compact this inner most 3 feet as

detailed in Figure 840.06.I.3. Within 3

feet of the wall, the SGB is compacted with six passes of a mechanical tamper

or vibratory plate compactor. The

compaction equipment should have a centrifugal force between 1/2 to 2 tons.

Figure

840.06.I.3 Place and Compact the SGB

Next to the Facing Panels

Use the procedure detailed in

Figures 840.06.I.2 and 840.06.I.3 for the SGB placement and compaction

procedure for the remaining sections of wall.

The SGB is placed in maximum

8-inch loose lifts. It may be helpful to

mark the lift thicknesses on the back side of the wall panels. The action of moving the SGB parallel to the

wall and windrowing or compacting the material toward the reinforcement ends

and away from the wall takes out the slack in the reinforcement and locks the

reinforcement and the panels in position.

Figure 840.06.I.4 Improper Spreading Technique

(From back to front is improper)

Any slack in the

reinforcement should be removed to avoid excessive panel movement. With geogrid soil reinforcement, some tension

needs to be applied to the reinforcement by means of a kicker tension device or

a rod during this backfill placement.

Figure

840.06.I.5 Final Compaction Operation Next to the Wall

Consistent placement and

compaction of SGB are one of the keys to a good performing MSE wall.

Inspection and Compaction Testing

(840.06.N)

No compaction testing is

performed on the SGB within 3 feet of the wall. For the SGB, more than 3 feet

from the wall facing panels, smooth-drum vibratory rollers weighting between 6

and 10 tons are required to compact the material. The compaction testing is performed according

to Supplement 1015

and SS 878.

SS 878

details the general inspection and compaction testing requirements when

these services are hired through the Contractor. All of the inspection and compaction

procedures that are required for ODOT inspection personnel are required for the

Contractor’s personnel under SS 878. A trained compaction and inspection person is

required under this specification. All

of the Department inspection and compaction forms are to be used.

Supplement 1015

details the inspection and compaction procedures to be employed during the

work.

At the beginning of the work,

a test section is constructed to determine the density requirements for the

select granular backfill. The moisture requirements are determined by using the

moisture density curve for the Method A test section. For the Method B test section, the moisture

requirements are determined by constructing several test sections at different

moisture contents. For determining which

test section is used, see Supplement 1015.

The select granular material

is compacted between 3 percent below and optimum moisture content. If additional water is required after

spreading the material, then water must be added to meet these

requirements. The moisture content of

the select granular backfill material prior to and during compaction is to be

uniformly distributed throughout each layer of material. If watering is required after spreading, the

project should dig up the material to ensure that this requirement is met.

Figure

840.06.N.1 Taking a Compaction Tests

Once the moisture content is

correct, the test section is constructed to determine the density requirements

for the remaining areas of the select granular backfill. This test section is

approximately 40 square yards. This test

section is compacted until a maximum density is achieved. The number of passes and the maximum density

is used in the remainder of the work. A minimum of 98 percent of the maximum

density is required. A new test section

should be constructed if the compaction tests are not close to the maximum

value. Use the same number of passes if the material or foundation conditions

change.

In the figure below, the

compaction starts 3 feet away from the wall and proceeds to the back of the

soil reinforcement. In the background,

the area within 3 feet from the wall is compacted after the roller compaction

is complete. This procedure is detailed

in the previous section.

Figure

840.06.N.2 Smooth-drum Vibratory Compaction Equipment

Wall Drainage (840.06.F)

At the end of each day’s

operation, the Contractor is to shape the last layer of backfill to allow

rainwater to runoff away from the wall face.

The drainage system is under or in front of the wall. This will permit

the water to dissipate from the system.

The SGB of the wall can be drained laterally to dissipate out to the

sides. Drainage problems can develop

similar to the figure below.

Figure

840.06.F.1 Washout around the Soil

Reinforcement

Water ponding in front of the

wall has been a problem is the past. In the

figure below, you can see the ponding of the water in front of the wall. This is not acceptable.

Figure

840.06.F.2 Water Ponding in Front of the

Wall

It is required to pump the

water out of this area immediately after the water is ponded. In addition, once the wall is erected up to

the ground elevation, this void is filled with embankment material. This will further stabilize the wall.

If water is ponding behind

the wall during construction as shown below:

Figure

840.06.F.3 Water Ponding Behind the Wall

Then collect the water by

using a drainage curtain as detailed below:

Figure

840.06.F.4 Drainage Blanket

Side slope erosion has been a

problem in the past. One solution has

been to construct 2 feet of embankment on the side slopes. This will bury the highly

erosive select granular material and erosion can be minimized.

Figure

840.06.F.5 Protection of the Erosive Side Slopes with Embankment

Soil Reinforcement Installation (840.06.H)

Soil Reinforcement Storage

The soil reinforcement is

used to tie the wall to the soil. Like

the panels, the soil reinforcement should be stored on dunnage and carefully

handled to prevent damage. Damage may

include bending of the metallic reinforcement and damaging the

galvanization. The geogrid soil

reinforcement should not be torn, cut, left in the sun, or otherwise damaged.

No equipment should be

allowed to run directly on the reinforcement.

Figure 840.06.H.1

Reinforcement Storage on Dunnage

The project should check for

required length and gauge of steel reinforcement. Check the condition of steel reinforcement

upon delivery to the site. Below is a

typical plan view of the soil reinforcement on a project. The length of the reinforcement from the wall

is directly proportionate to the height of the wall. The wall height below is the highest in the

center and the length of the reinforcing is the longest. The length of the reinforcing cannot change

from the bottom to the top of the wall.

It can only change along the wall due to changes in the height or design

changes.

Figure

840.06.H.2 Typical Reinforcement Layout

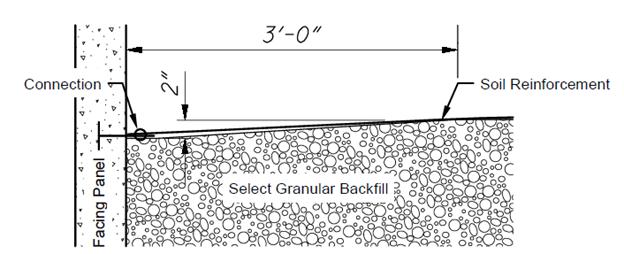

Below is a detail of a

cross-sectional view of the soil reinforcement in the same wall. Notice the soil reinforcement connection to

the wall and regular intervals. The

length of the reinforcement is the same from the bottom of the wall to the top

of the wall. Many of these walls are

placed below an abutment as detailed below.

Figure

840.06.H.3 Cross-Section of the Soil

Reinforcement Layout

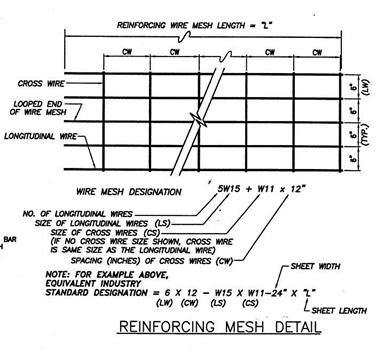

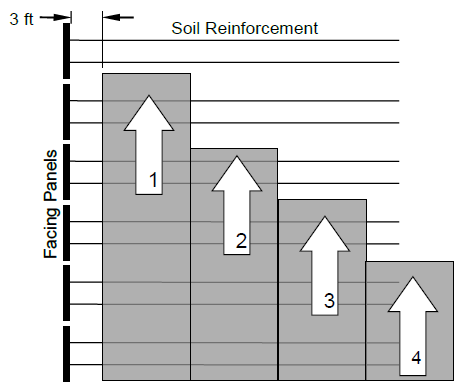

Below are the reinforcing

mesh codes for a Foster wall. These

codes were used on past projects. For

Foster walls, the reinforcing mesh will change frequently. The project should familiarize themselves

with the codes on the shop drawings and ensure that the correct mesh types are

placed in the proper location.

The figure below details the

wire mesh codes. Careful review of these

keys is required by the project.

Figure

840.06.H.4 Reinforcing Mesh Details

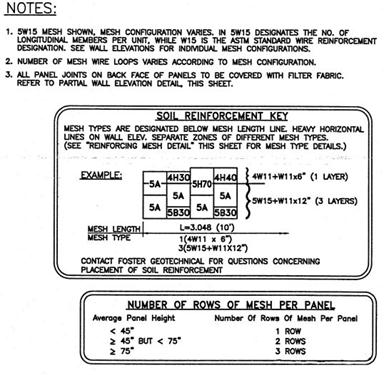

Below is a sample of how the

reinforcing mesh is laid out as it relates to the panels. The panels are numbered in the example and

the type of reinforcing mesh is detailed beside the panel type.

Figure

840.06.H.5 Reinforcing Panel and

Reinforcing Key

Typically, the reinforcement

is placed perpendicular to the wall face. Any slack in the reinforcement should

be removed. The geogrid soil

reinforcement should have some tension placed in the reinforcement. By using the placement and compaction procedure

detailed in the previous section, it will keep the tension in the soil reinforcement.

Once the fill is compacted to

the elevation of the soil reinforcement, the soil reinforcement can be attached

to the facing panels and placed perpendicular to the face of the wall on top of

the compacted material.

Connections

Connecting the soil

reinforcing to the wall is relatively simple operation. There are three connections that will be

detailed below.

Reinforced Earth Connection

A Reinforced Earth wall’s

connections and soil reinforcement consist of galvanized strips, tabs

manufactured in the wall, and nuts and bolts to connect them. There are tabs with holes that stick out of

the wall about 3 inches. The tabs have a

top and bottom and go around the strips when they are connected.

Figure

840.06.H.6 Reinforced Earth Connections

and Strips

At times, there is concrete

inside the tabs that make it difficult to place the strips inside the

tabs. The concrete needs to be cleaned

out to line up the holes. Many times the

Contractor will cut the strips instead of cleaning out the concrete. Do not allow the strips to be cut in the

field. This can reduce the strength of

the connection. Also, the galvanizing of the strip will be compromised and the

strip will prematurely rust.

Figure

840.06.H.7 Tabs for Reinforced Earth Connections

Once the holes are lined up,

the bolt is inserted from the bottom up and the nut is tightened. By placing the bolt from the bottom, it is

easy to see if the nut has been placed on the connection.

Figure

840.06.H.8 Bolted Reinforced Earth Connection

Below are multiple strips

connected to the wall for a Reinforced Earth wall. Leaving the select granular backfill lower at

the tabs is acceptable. The select

granular backfill needs to be as close to the strips as possible for all wall

types.

Figure

840.06.H.9 Reinforced Earth Multiple Connections to the Wall

Wire Mesh Connection

The connection for steel wire

mesh soil reinforcement consists of hooked eyelets in the panels and

reinforcing mesh with two transverse bars at the end. The end of the wire mesh is laid with the two

transverse bars resting on top of the hooked eyelets. A rod is inserted through the eyelets,

locking the mesh into place, as shown below.

Wooden wedges are then hammered between the wall and the mesh to put the

eyelets in full contact with the mesh and the soil reinforcement in tension.

Figure

840.06.H.10 Wire Mesh Type Connection

Below is a typical layout of

the soil reinforcement of a wire mesh wall.

Figure

840.06.H.11 Mesh Steel Laid Out

Geogrid Soil Reinforcement

Connection

The connection for geogrid soil

reinforcement consists of short sections of geogrid cast into the panels and a

plastic bodkin bar. The ribs of the

geogrid soil reinforcement are meshed with the short sections of geogrid that

are cast into the panels. The plastic bodkin is then weaved between the two

sets of ribs and the soil reinforcement is pulled tight. The completed connection is shown below.

Figure

840.06.H.12 Geogrid Soil Reinforcement Connection

Figure

840.06.H.13 Overview of Geogrid Soil Reinforcement

Obstructions

There are times when the soil

reinforcements have to go around obstructions.

It is not acceptable to simply leave out the reinforcement at that

location. This would create a weak

location along the wall.

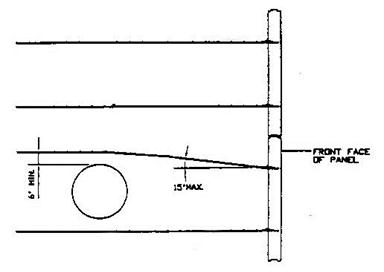

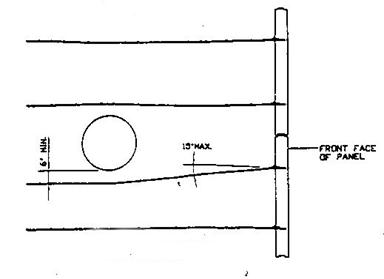

At horizontal obstructions,

such as pipes, the reinforcement should not be angled more than 15 degrees up

or down. All situations that exceed 15

degrees must be detailed on the accepted shop drawings or acceptable to the Office

of Geotechnical Engineering. The

soil reinforcement must have a 4 inch clearance above or below the

obstruction. When clearing horizontal

obstructions, the reinforcement should be smoothly curved around the

obstruction. The reinforcement should

not be kinked at any time.

The detail below shows a

horizontal obstruction lower than the soil reinforcing and connection.

Figure

840.06.H.14 Soil Reinforcement going

over a Horizontal Obstruction

The detail below shows a horizontal

obstruction higher than the soil reinforcing and connection.

Figure

840.06.H.15 Soil Reinforcement going under a Horizontal Obstruction

The photo below shows the

soil reinforcement going under a storm sewer line.

Figure

840.06.H.16 Soil Reinforcement going

under a Storm Sewer Line

At vertical obstructions,

such as piles or catch basins, if the reinforcement must be splayed more than

15 degrees for steel strips or 5 degrees for geosynthetic strips from

perpendicular to the facing panels, the accepted shop drawings should detail a

modification. All situations that exceed

the 15 or 5 degree limits must be detailed on the accepted shop drawings or

acceptable to the Office

of Geotechnical Engineering. It may

require additional reinforcement length to meet design.

Figure

840.06.H.17 Soil Reinforcement Splayed

Around Piles

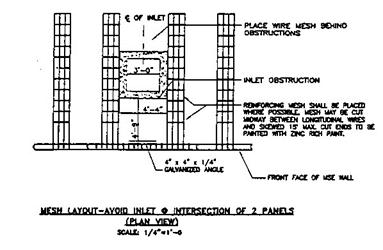

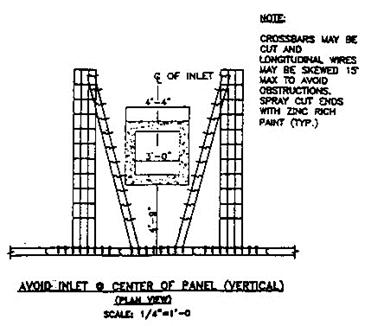

In the detail below, the soil

reinforcement was designed around the inlet by using a galvanized angle in

front of the inlet and keeping the reinforcing steel perpendicular to the

wall. Again, this would have to be

detailed on the acceptable shop drawings.

Figure

840.06.H.18 Typical Details for Obstructions

Below

is a photo of the galvanized angle in front of the catch basin to allow the

soil reinforcement to be placed around the catch basin.

Figure

840.06.H.19 Field Example of the Reinforcing Around an Obstruction

In the detail below, the

reinforcing mesh is cut and splayed around the inlet. No angle is required in front of the inlet.

Figure

840.06.H.20 Cutting the Mesh to go

around the Obstruction

Coping (840.06.K)

The coping is placed on the

top of the wall. It is used to smooth out

the appearance of the top of the wall and to connect adjacent panels at the top

of the wall. The wall is completed when

the coping is properly installed on top of the wall. The coping has to be cast in place on the top

of the wall.

Here is the typical form and

reinforcing steel for the coping.

Figure

840.06.K.1 Forming the Coping

Moment Slab

The moment slab is put on the

top of the wall to prevent vehicles from going off the roadway. It must have a large support system to resist

these loads. The reinforcing steel is

shown below.

Figure

840.06.K.2 Moment Slab Reinforcing Steel

The finished moment slab is shown

below.

Figure

840.06.K.3 Completed Moment Slab

If your project has a

concrete pavement on top of the wall, there may be a problem with crack

propagation of the barrier joints on to the pavement. Review these details carefully and make

adjustments as required.

Figure

840.06.K.4 Align the Joints of the

Barrier and the Concrete Pavement

Design Conflicts, Design and

Construction Loads

Before the actual start of

construction of the wall, the various parts of the plans (shop drawings,

drainage, lighting, etc.) need to be compared to the contract wall plans to

check for conflicts. A conflict may not

have been noticed in the design stage.

If the plans show heavy loads on the wall and the shop drawings do not

indicate it, the Office

of Geotechnical Engineering should be contacted. The Designer may have missed loadings from

various types of structures. If they did

not take these loads into consideration, the wall could bow or even fail. This also can happen for temporary loads that

the Contractor may impose, such as pile driving.

Final Checks

There are various items that

need to be evaluated at the end of the project, such as sand leaking out of the

joints, open joints, exposed fabric settlement, and more.

There are multiple PowerPoint

presentations on the ODOT website. The

websites are as follows:

http://www.dot.state.oh.us/Divisions/ContractAdmin/Contracts/Conaway/Forms/AllItems.aspx

http://www.dot.state.oh.us/Divisions/Engineering/Structures/standard/MSE/Pages/default.aspx

The following is a general checklist

to follow when constructing a Mechanically Stabilized Earth wall (MSE wall).

The answer to each of these should be yes unless the plans, specifications, or

specific approval has been given otherwise.

YES NO

¨ ¨ 1. Has the Contractor submitted wall shop

drawings?

¨ ¨ 2. Has the Contractor submitted select granular

backfill certified test data?

¨ ¨ 3. Has the Contractor supplied a wall supplier’s

construction manual?

¨ ¨ 4. Have the shop drawings been accepted?

¨ ¨ 5 Do we have the correct panels (shape, size,

and soil reinforcement connection layout) per the accepted shop drawings?

¨ ¨ 6. Do we have the correct reinforcement (proper

length and size)?

¨ ¨ 7. Have the panels and the reinforcement been

inspected for damage as outlined in the specifications?

¨ ¨ 8. If any panels or soil reinforcement were found

damaged, have they been rejected or repaired in accordance with the

specifications?

¨ ¨ 9. Are the panels and the soil reinforcement

properly stored to prevent damage?

¨ ¨ 10. Has the MSE wall area been excavated to

the proper elevation?

¨ ¨ 11. Has the foundation been properly

evaluated?

¨ ¨ 12. Has the drainage for the wall been

installed?

¨ ¨ 13. Has the leveling pad area been properly

excavated?

¨ ¨ 14. Has the leveling pad been set to the

proper vertical and horizontal alignment?

¨ ¨ 15. Has the leveling pad cured for a minimum

of 12 hours before any panels are set?

¨ ¨ 16. Is the first row of panels properly

placed? Do they have proper spacing, bracing, tilt, and where required, do they

have the spacers installed?

¨ ¨ 17. Has the proper filter fabric and adhesive

been supplied?

¨ ¨ 18. Is the filter fabric being properly

placed over the joints?

¨ ¨ 19. Is the adhesive being applied to the

fabric then onto the wall?

YES NO

¨ ¨ 20. Is the filter fabric being stored

properly (stored out of the sunlight and protected from UV radiation)?

¨ ¨ 21. Is the Contractor using the correct

panels (correct size, shape, and with the proper number of connections) for

that panel’s wall location and elevation?

¨ ¨ 22. Is the fill being placed and compacted in

8-inch loose lifts?

¨ ¨ 23. Is the equipment being kept off of the

soil reinforcement until a minimum of 8 inches of fill is placed?

¨ ¨ 24. Are the lifts being placed by the proper

method and sequence?

¨ ¨ 25. Is the fill being compacted by the

correct equipment and in the correct pattern?

¨ ¨ 26. Is the proper compaction being met?

¨ ¨ 27. Is the soil reinforcement being properly

connected (connections tight and all of the slack in the soil reinforcement

removed)?

¨ ¨ 28. Is the soil reinforcement in the proper

alignment?

¨ ¨ 29. Is the vertical and horizontal alignment

being checked periodically and adjusted as needed?

¨ ¨ 30. Is the Contractor removing the wooden

wedges as per the specifications? (The wooden wedges shall be removed as soon

as the panel above the wedged panel is completely erected and backfilled.)

¨ ¨ 31. At the end of each day’s operation, is

the Contractor shaping the last layer of backfill to permit runoff of rainwater

away from the wall face or providing a positive means of controlling runoff

away from the wall, such as temporary pipe, etc.?

¨ ¨ 32. Has the Contractor backfilled the front

of the wall?

¨ ¨ 33. Is the coping being installed correctly?

MSE Wall Construction Do’s and Don’ts

1. Review approved shop drawings.

2. Review the Section 840 in the MOP for Mechanically

Stabilized Earth (MSE) walls.

3. Verify leveling pad elevations.

4. Confirm fill material has been tested and approved

before it is brought to the job site.

5. Inspect panels.

6. Inspect soil reinforcement for damage.

7. Reject all panels that are not in compliance with the

plans and specifications.

8. Ensure panels, soil reinforcement, and filter fabrics

are properly stored to prevent damage.

9. Ensure the reinforcing can go around all obstructions

with less than 15 degrees of splay.

10. Install panels in accordance with the plans and

specifications.

11. Place and properly compact fill in accordance with

plans and specifications.

12. DO NOT use thick fill lifts. Fill lifts thicker than 8-inch loose lifts

require more energy to compact and may move the panels out of alignment.

13. Use corner panels at all corners. If corner panels are

not indicated on the plans, the designer should be notified.

14. Metallic soil reinforcement strips should not be

splayed more than 15 degrees from normal.

Geosynthetic soil reinforcement strips should not be splayed more than 5

degrees from normal. If reinforcement needs to be splayed more than the 15 or 5

degree limits, notify the designer.

15. Check the batter of the panels often. Adjust

accordingly. The vertical alignment of the panels below the panels being

installed may be affected by the compaction of the soil behind the panels being

installed.

16. Check overall batter regularly.

17. When attaching filter fabric to the back of the

panels, the adhesive shall be applied to the fabric, and then attached to the

panel.

Out of

Tolerances Conditions and Possible Causes Criteria

The following is taken out of

FHWA’s Publication, “Mechanically Stabilized Earth

Walls and Reinforced Soil Slopes Design & Construction Guidelines,” NHI

Course No. 132042.

MSE structures are to be

erected in strict compliance with the structural and aesthetic requirements of

the plans, specifications, and contract documents. The desired results can

generally be achieved through the use of quality materials, correct

construction/erection procedures, and proper inspection. However, there may be

occasions when dimensional tolerances and/or aesthetic limits are

exceeded. Corrective measures should

quickly be taken to bring the work within acceptable limits. Presented below are several out-of-tolerance

conditions and their possible causes.

Table

840.A – Out-of-Tolerance Conditions and Possible Causes

|

Distress |

Possible Causes |

|

1. Distress in wall: Differential settlement or low spot

in wall. Overall wall leaning beyond

vertical alignment tolerance. Panel contact, resulting in

spalling/chipping |

Foundation (subgrade) material too

soft or wet for proper bearing. Fill

material of poor quality or not properly compacted. |

|

2. First panel course difficult

(impossible) to set and/or maintain level. Panel-to-panel contact resulting in

spalling and/or chipping. |

Leveling pad not within tolerance. |

|

3. Wall out of vertical alignment

tolerance (plumbness), or leaning out. |

Panel not battered sufficiently. Oversized backfill placing and/or compaction

equipment working within 3 foot zone of back-of-wall facing panels. Backfill material placed wet of

optimum moisture content. Backfill

contains excessive fine materials (beyond the specifications for percent of

materials passing a No. 200 sieve). Backfill material pushed against

back of facing panel before being compacted above reinforcing elements. Excessive or vibratory compaction

of uniform, medium-fine sand (more than 60 percent passing a No. 40 sieve). Backfill material dumped to close

to free end of reinforcing elements, then spread toward back-of-wall, causing

displacement of reinforcements and pushing panel out. Shoulder wedges not seated

properly. Shoulder clamps not tight. Slack in reinforcement to facing

connections. Inconsistent tensioning of the

geosynthetic reinforcement. Localized over compaction |

|

4. Wall out of vertical alignment

tolerance (plumbness) or leaning in. |

Excessive batter set in panels for

select granular backfill material being used. Inadequate compaction of the backfill. Possible bearing capacity failure. |

|

5. Wall out of horizontal alignment

tolerance, or bulging. |

Backfill material placed wet of

optimum moisture content. Backfill

contains excessive fine materials (beyond the specifications for percent of

materials passing a No. 200 sieve). Backfill material pushed against

back of facing panel before being compacted above reinforcing elements. Excessive or vibratory compaction

of uniform, medium-fine sand (more than 60 percent passing a No. 40 sieve).

Inconsistent tensioning of the geosynthetic reinforcement. Localized over compaction. Backfill saturated by heavy rain or

improper grading of backfill after each day’s operations. |

|

6. Panels do not fit properly in

their intended locations. |

Panels are not level. Differential settlement (see Cause 1). Panel cast beyond tolerances. Failure to use spacer bar. |

|

7. Large variations in movement of

adjacent panels. |

Backfill material not uniform. Backfill compaction not uniform. Inconsistent setting of facing panels. |

Documentation

Requirements – 840 MSE Walls

1. Did the panels arrive with a TE-24?

2. Were the panels rejected or repaired as per the

specifications?

3. Was the select granular material approved?

4. If the wall was in a cut, were the sidewalls properly

protected?

5. Was the foundation properly prepared?

6. Was the drainage properly constructed?

7. Was the filter fabric properly placed?

8. Was the foundation undercut properly constructed?

9. Was the leveling pad placed as specified?

10. Were the wall panels placed according to the plan and

markings on the back of the panels?

11. Was external bracing used for the first lift of

panels?

12. Were the horizontal and vertical tolerances met?

13. Was the soil reinforcement placed perpendicular to the

wall face?

14. Was the SGB placed in 8-inch lifts?

15. Was the backfill compacted to the specification

requirements?

16. Was the backfill within 3 feet of the wall compacted

to the specification requirements?

17. Did a manufacturer’s representative inspect the site

during the wall construction?

18. Did the soils consultant properly take the compaction

tests?

19. Was the coping and traffic barrier constructed

properly?

20. Were the pile sleeves constructed properly?

21. Perform all the compaction tests according to

S-1015 or SS-878.

22. Document on the CA-EW-1,CA-EW-3, CA-EW-8, CA-EW-12,

and CA-D-3. Do not duplicate the

information on all forms unless necessary.

SUPPLEMENTAL

SPECIFICATION 840

MECHANICALLY STABILIZED EARTH WALL

April 19, 2013

840.01 Description

840.02 Definitions

840.03 Materials

840.04 Design and Submittal Requirements

840.05 Fabrication and Acceptance of Precast Concrete

Facing Panels

840.06 Construction

840.07 On-Site Assistance

840.08 Method of Measurement

840.09 Basis of Payment

Appendix A

– MSE Wall Acceptance Letter

840.01 Description. This work

consists of designing for internal stability, preparing shop drawings, and

fabricating and constructing a mechanically stabilized earth (MSE) wall using an accredited MSE

Wall System. This specification

supersedes recommendations by the MSE wall system

supplier.

840.02 Definitions. For the

purposes of this specification, the following definitions are used:

A. MSE Wall System. A retaining wall system that consists of

select granular backfill, reinforcing elements, and facing elements connected

to the soil reinforcement.

B. Soil

Reinforcement. A material placed within a soil mass to increase the strength of

the select granular backfill. Soil

reinforcement for MSE walls are typically placed

horizontally and consist of steel strips, welded wire mesh, or geosynthetics (polymer mesh or strips).

C. Facing

Panels. The component of an MSE wall

used to contain the Select Granular Backfill in position at the face of the

wall. Facing panels for MSE walls are typically made of precast concrete.

D. Connection

Device. The item used to connect the soil reinforcement to the facing

panel.

E. MSE Wall System Supplier. The Contractor or Consultant

that designs the MSE wall system for internal

stability and in accordance with the plans, designs the components of the MSE wall system and prepares the shop drawings.

F. Accredited

MSE Wall System.

An MSE

wall system approved for use by the Office of Geotechnical Engineering. Each accredited MSE

wall system has specific designs for the soil reinforcement, facing panels, and

connection devices. The following table

lists the accredited MSE wall systems and the

associated MSE wall system suppliers.

Table 840.02-1

|

Accredited MSE wall system |

MSE wall system supplier |

|

Reinforced Earth |

The Reinforced Earth

Company |

|

Retained Earth |

The Reinforced Earth

Company |

|

MSE Plus |

SSL, LLC |

|

Tricon Retained Soil |

Tricon Precast |

|

ARES |

Tensar Earth Technologies |

|

EarthTrac HA |

EarthTec |

|

GeoMega |

The Reinforced Earth

Company |

|

Sine Wall |

Sine Wall, LLC |

G. Precaster. A manufacturer certified by the Department

according to Supplement 1073 to produce precast concrete products. The Precaster

furnishes the facing panels for the accredited MSE

wall system.

A. Precast Concrete Facing Panels. Furnish

materials conforming to the following:

Portland cement................................... 701.02, 701.04, or 701.05

Reinforcing steel................................................................. 709.00

Microsilica.......................................................................... 701.10

Ground granulated blast furnace slag (GGBFS)................ 701.11

Fly ash................................................................................ 701.13

Fine aggregate.................................................................... 703.02

Coarse aggregate................................................................ 703.02

Air-entraining admixture.................................................... 705.10

Chemical admixtures.......................................................... 705.12

B. Soil

Reinforcement. Furnish soil reinforcements and connection devices

conforming to the requirements for the appropriate accredited MSE wall system listed below. Provide certified test data for all of the

requirements. Refer to the shop drawings

for the shape and dimensions of soil reinforcements.

Store soil reinforcements

off the ground and protect against weather by covering with tarps. Do not bend steel soil reinforcements after

galvanizing.

1. Reinforced Earth

Furnish soil reinforcement consisting of steel strips or ladders. Furnish steel strips conforming to ASTM A 572, Grade 65 (ASTM A 572M, Grade 450). Furnish ladders conforming to ASTM A 185 (ASTM A 185M). Furnish soil reinforcement galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish connection devices consisting of tie strips or tie plates conforming to ASTM A 1011, Grade 50 (ASTM A 1011M, Grade 340) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish bolts conforming to ASTM A 325 or ASTM A 449. Furnish nuts conforming to ASTM A 563 and washers conforming to ASTM F 436. Furnish bolts, washers and nuts that are galvanized according to the requirements of ASTM F 2329 or ASTM A 153 (ASTM A 153M).

2. Retained Earth

Furnish soil reinforcement consisting of welded wire mesh conforming to ASTM A 185 (ASTM A 185M) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish connection devices consisting of clevis loops and connector rods conforming to ASTM A 82 (ASTM A 82M) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M).

3. MSE Plus

Furnish soil reinforcement consisting of welded wire mesh conforming to ASTM A 185 (ASTM A 185M) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish connection devices consisting of loop embeds and connecting pins conforming to ASTM A 82 (ASTM A 82M) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M).

4. Tricon Retained

Soil

Furnish soil reinforcement consisting of welded wire mesh conforming to ASTM A 185 (ASTM A 185M) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish connection devices consisting of panel anchors and locking rods conforming to ASTM A 82 (ASTM A 82M) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M).

5. ARES

Furnish soil reinforcement consisting of high density polyethylene (HDPE) geogrids and connection devices consisting of HDPE geogrids and bodkin bars. Furnish either UX1400MSE, UX1500MSE, UX1600MSE or UX1700MSE geogrids from Tensar Earth Technologies, that conform to the following requirements.

Table 840.03-1

|

|

UX1400MSE |

UX1500MSE |

UX1600MSE |

UX1700MSE |

|

Minimum Tensile Strength ASTM D 6637 |

4,800 lb/ft (70 kN/m) |

7,810 lb/ft (114 kN/m) |

9,870 lb/ft (144 kN/m) |

11,990 lb/ft (175 kN/m) |

6. EarthTrac HA

Furnish soil reinforcement consisting of steel strips conforming to ASTM A 572, Grade 50 (ASTM A 572M, Grade 345) and galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish connection devices consisting of either single lugs conforming to ASTM A 572, Grade 50 (ASTM A 572M, Grade 345) or double lugs conforming to ASTM A 36. Furnish connection devices that are galvanized according to the requirements of ASTM A 123 (ASTM A 123M). Furnish bolts and nuts conforming to ASTM A 325 (ASTM A 325M) and galvanized according to the requirements of ASTM A 153 (ASTM A 153M).

7. GeoMega

Furnish soil reinforcement consisting of high tenacity polyester (HTPET) geosynthetic strips encased in a polyethylene sheath and connection devices consisting of injection-molded polypropylene sleeves. Furnish either GS1, GS2, or GS3 geostraps from The Reinforced Earth Company, that conform to the following requirements.

Table 840.03-2

|

|

GS1 |

GS2 |

GS3 |

|