702 ASPHALT MATERIAL

Acceptance. Asphalt binders 702.01 and liquid asphalts 702.02, 702.03, and 702.04 may be acceptable for shipment to and

immediate use in construction projects. Acceptance is according to

Supplement 1032.

702.00 Application

Temperatures. Apply

asphalt materials, according to the temperature ranges specified in Table 702.00-1.

|

Type and Grade of Material |

Application Temperature Range °F

(°C) |

|

|

Spray |

Mix |

|

|

MC-30 |

50 to 120 (10 to 49) |

--- |

|

MC-70 |

75 to 150 (24 to 66) |

--- |

|

MC-250 |

100 to 225 (38 to 107) |

100 to 225 (38 to 107) |

|

MC-800 |

150 to 250 (66 to 121) |

150 to 225 (66 to 107) |

|

MC-3000 |

225 to 275 (107 to 135) |

200 to 250 (93 to 121) |

|

All Emulsions |

50 to 160 (10 to 71) |

50 to 140 (10 to 60) |

|

Asphalt Primer for Waterproofing |

50 to 80 (10 to 27) |

--- |

|

Asphalt for Waterproofing |

300 to 350 (149 to 177) |

--- |

|

CBAE 350, CBAE

350 SP |

100 to 150 (38 to 66) |

100 to 150 (38 to 66) |

|

CBAE 800, CBAE

800 SP |

125 to 175 (52 to 79) |

125 to 175 (52 to 79) |

|

Primer 20 |

60 to 120 (16 to 49) |

--- |

|

Primer 100 |

75 to 125 (24 to 52) |

--- |

|

Asphalt Binders |

350 (177) Max. |

325 (163) Max. |

|

Asphalt Binders Polymer modified with SB, SBR, SBS, or Elvaloy |

375 (190) Max |

350 (177) Max. |

General. According to AASHTO M 320-10 Table 1 except as follows.

PG Binders with the

suffix “M” (e.g., PG 70-22M, PG 76-22M) will meet the requirements of Table 702.01-1. When a PG 64-28 is made through modification ensure it meets the test requirements of Table 702.01-1.

An independent

laboratory will not be owned or operated, in whole or part, by the binder

supplier, Contractor, or affiliates of either.

Materials

and Manufacture. Replace the

requirements of AASHTO M 320-10 Table 1 Section 5 “Materials and

Manufacture” Section with the following:

5.1

Supply PG Binder from the refining of crude petroleum, or combination of

asphalt binders from the refining of crude petroleum, or asphalt binders and

suitable liquid from the refining of crude petroleum, and possible organic

modifiers for performance enhancement. Material from the crude refining

stream is considered neat. Liquid from crude refining may be used for

adjustments, but do not used liquid from crude refining for the purpose of

substitution of crude refined asphalt binder in a PG Binder. In the event

of a failure investigation where asphalt binders exhibit unusual properties a

supplier may be requested by the Laboratory to supply information about the

makeup of a PG Binder. Failure to cooperate will mean removal from

Supplement 1032

certification.

5.2

A modifier may be any organic material of suitable manufacture that is proven

compatible with asphalt binder (does not separate appreciably in routine

storage), and that is dissolved, dispersed or reacted in asphalt binder to

improve its performance. Performance enhancement is defined as a decrease

in the temperature susceptibility of the asphalt binder while maintaining or

improving desirable properties in a neat asphalt binder such as coatability, adhesiveness and cohesiveness. Limit

modifiers to no more than 6.0 percent by PG Binder weight.

5.3

The use of previously used materials in a PG Binder must be approved by the

Department. Since no standard test procedures exist for reprocessed

materials (and original tests were not developed with the use of such materials

in mind), appropriate test methods may be chosen by the Department for

review. Department approval does not relieve the binder supplier from

full responsibility for content and use of any previously used material in a PG

Binder nor guarantee suitable performance enhancement as defined above.

The detected presence in a PG Binder sample of any unapproved previously used

material will mean immediate removal from Supplement 1032 certification.

Limit approved reprocessed materials to 6.0 percent by PG Binder weight.

5.4

Ensure the PG Binder is homogeneous, free from water and deleterious materials,

and does not foam when heated to 350 ºF (175 ºC). Prove the asphalt

binder (before modification or after modification if liquid modifier used) is

fully compatible with a negative result by means of the Spot Test per AASHTO T 102 using standard naphtha

solvent. If standard naphtha shows a positive result, a retest

using reagent grade 35 percent Xylene/ 65 percent Heptane (volume) may be

used.

5.5

Ensure the PG Binder is at least 99.0

percent soluble as determined by ASTM D 5546 or D 2042. Ensure any

insoluble component is free of fibers or discrete particles more than 75 µm.

5.6

Ensure flash point is 500 ºF (260 ºC) minimum. Ensure mass loss on RTFO of the final PG Binder grade is 0.5 percent maximum.

5.7 Ensure that PG 64-22 has a Penetration (AASHTO T49

) of no more than 75.5.8

Direct Tension testing is not required, unless otherwise required in this

specification.

a. Pre-blended

Binder. Usea base binder of at least -22 grade or stiffer for 70-22M and

76-22M.

c. Without Direct Tension, graded with actual pass temperatures

e. ASTM D 6084, 10cm

@ 77 ºF (25 ºC), hold 5 min. before cutting, on RTFO

material

f. ASTM D 5801,

50cm/min @ 77 ºF (25 ºC)

j. ASTM D 113, @ 39 ºF (4 ºC), 1 cm/min

702.02 Cut-Back

Asphalt. Provide medium curing cut-back asphalt

according to AASHTO M 82.

Instead of viscosity on the residue, the penetration in note 2 (AASHTO M 82)

will govern.

702.03 Cut-Back Asphalt Emulsions. Prepare emulsions by compounding a suitable volatile solvent and

water with 702.01 asphalt to produce emulsions according to

Table 702.03-1.

702.04 Emulsified Asphalts. Provide

emulsified asphalts according to AASHTO M 140 or AASHTO M 208 and

specification limits will be producible for at least 30 days from project

delivery.

702.05 Asphalt Primer for Waterproofing. Provide asphalt primer for waterproofing according to ASTM D 41 Type

2.

Furnish materials according to the

Department’s Qualified Products List (QPL).

702.06 Asphalt for Waterproofing. Provide asphalt for waterproofing according to

ASTM D 312, Type

III.

Furnish materials according to the

Department’s Qualified Products List (QPL).

702.07 Asphalt Emulsion MWS. Prepare asphalt emulsion MWS from a base

material according to 702.01, except vary the penetration to meet the float

test and penetration specified below. Ensure that the emulsion coats the

aggregate readily, thoroughly, and uniformly. Ensure that the specified

characteristics do not change during transportation, normal storage and that

the emulsion is according to the following when tested according to AASHTO T 59 for at

least 30 days after application:

702.13 SBR Asphalt Emulsion. Provide material consisting of asphalt emulsion SS-1, SS-1h, CSS-1

or CSS-1h per 702.04 and

Supplement 1032, blended

with SBR emulsion per 702.14, to produce

a residual mixture of asphalt binder and SBR solids

having a composition of 97.0 ± 0.3 percent asphalt binder and 3.0 ± 0.3 percent

SBR solids by weight.

Furnish a certification to the Engineer and signed by the

contractor containing the following:

A. The weight of SBR emulsion blended with the asphalt emulsion.

B. The weight of asphalt

emulsion blended with the SBR emulsion.

C. The SBR

emulsion manufacturer certification per 702.14.

D. The percent of asphalt

binder in the asphalt emulsion (residue by distillation).

E. The percent of SBR solids in the SBR emulsion.

F. The percent of SBR solids in the mixture of asphalt binder residue and SBR solids.

G. Name of Certified asphalt

emulsion producer and asphalt emulsion.

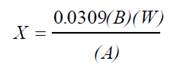

X = pounds (kilograms) of SBR emulsion

A = percent SBR

solids in the SBR emulsion

B = percent of asphalt residue of the

asphalt emulsion

W = pounds (kilograms) of the asphalt

emulsion

702.14 SBR

Emulsion. Ensure the SBR

emulsion is a cold polymerized Styrene Butadiene synthetic rubber (SBR) in latex form specifically compounded for use in

asphalt binders and asphalt emulsions. Ensure the manufacturer of the SBR emulsion furnishes a written certification of the total

SBR solids content of the SBR

emulsion and actual test results showing compliance with both of the following

requirements:

B. Combination of 3.0 – 4.0

% SBR solids with 96.0 – 97.0 % PG 64-22 meeting 702.01 by weight:

Toughness

inch-pounds (N×m), Minimum

133 (15)

Tenacity,

inch-pounds (N×m), Minimum

80 (9)

702.16 Polymer Emulsified

Binder. Material will meet specification requirements

of the table below for at least 30 days after application

Table 702.16 Polymer Emulsified Binder

|

Elastic

Recovery, 50 ºF (10º C), %, min AASHTO T 301,

(e),(,g) |

||

|

Toughness/Tenacity,

77 ºF (25º C), 50 cm/min, Nm ASTM D 5801 (f)

|

||

(c)

HFRS-2P, test within 20 days of project sampling.

A. Type I Crack Sealant.

Conform to 705.04

Denier; ASTM D 1577*......................................

3.0 to 6.0

Length...........................

0.25 ± 0.02 inch (6.35 ± 0.51mm)

Crimps; ASTM D 3937.............................................

None

Tensile str, min. ASTM D2256*.....

70,000 psi (483 Mpa)

Specific

gravity................................................ 1.32 to 1.40

Minimum melting

temperature................... 475 ºF (256 ºC)

Ignition

temperature......................... 1000 ºF (538 ºC) min.

*This data must be obtained prior to

cutting the fibers.

The fiber and fiber manufacturer must

be on the Qualified Products List.

Strength (at break) at 72 ºF (22 ºC) 350 psi (2.4 MPa)

min.

.... at 0 ºF (-18 ºC) ......................... 500 psi (3.5 MPa) min.

Elongation (at break) at 72 ºF

(22 ºC) 50 percent min.

.... at 0 ºF (-18 ºC) ..................................... 20

percent min.

Denier; ASTM D 1577*...........................................

15 ±3

Length,........................... 0.39 ± 0.08

inch (9.91 ± 2.0 mm)

Crimps; ASTM D 3937.............................................

None

Tensile strength, min, ASTM D 2256*

40,000 psi (276 MPa)

Specific

gravity................................................. 0.91 ± 0.04

Minimum melting

point............................. 320 ºF (160 ºC)

* This data must be

obtained prior to cutting the fibers.

The fiber and fiber manufacturer must

be on the Qualified Products List.

Strength (at break) at 72 ºF (22 ºC) 350 psi (2.4 MPa)

min.

.... at 0 ºF (-18 ºC).......................... 500 psi (3.5 MPa) min.

Elongation (at break).................................. at 72 ºF (22 ºC)

50 percent min.

.... at 0 ºF (-18 ºC) ..................................... 20

percent min.

Cone

penetration, 77 ºF (25 ºC)................................ 50-90

Flow, 140 ºF

(60 ºC)........................................ 1.0 cm max

Resilience,

77 ºF (25 ºC)............................... 25-60 percent

Ductility, 77

ºF (25 ºC)...................................... 40 cm min

Bond, 0 ºF

(-18 ºC), 100 percent ext. Pass ........... 5 cycles

Impact, 0 ºF

(-18 ºC)................................................... Pass

Compression

recovery.......................................... 0.40 min

Recommended

pour temperature............... 380 ºF (193 ºC)

Safe heating

temperature............................ 410 ºF (210 ºC)

Safe heating temperature............................

400 ºF (204 ºC)

Softening

point............................................ 190 ºF (88 ºC)

Viscosity,

400 ºF (225 0C).............................. 3000 cp min

Cone

penetration, 77 ºF (25 ºC)................................ 25-45

Flexibility*..................................................................

Pass

* 1 inch

(25mm) sample at -20 ºF (-30 ºC), 90 degree bend, 10 sec

Crack sealant

and crack sealant manufacturer must be on the Qualified Products List.