257 Diamond Grinding Portland Cement Concrete Pavement

Method of Measurement (257.05)

Documentation Requirements – 257 Diamond Grinding Portland Cement Concrete Pavement

Description (257.01)

This work consists of diamond grinding a rigid concrete pavement normally the full width of the lane to eliminate transverse cracking and transverse joint faulting. The work results in a longitudinal “corduroy” texture. If done properly the ride of the finished pavement surface will be improved and the skid resistance enhanced.

Final acceptance of a diamond ground pavement is done by surface measuring equipment that is passed over the completed pavement and measures the surface profile. This equipment is called a non-contact profilometer or a profiler.

Equipment (257.02)

Figure 257.A - Types of Diamond Grinding Equipment

Figure 257.A - Types of Diamond Grinding Equipment

Equipment requirements for diamond grinding:

§ Must be power driven, self-propelled machine specifically designed to smooth and texture Portland cement concrete pavement with diamond blades or diamond impregnated cylinder rings

§ Diamond blades or diamond impregnated cylinder rings must be mounted on an arbor head that is a minimum of 3 feet long

§ Must be capable of grinding the surface in the longitudinal direction without causing spalling or other damage at cracks, joints and other locations

§ Must be capable of correcting the pavement profile and providing proper transverse cross slope

§ The effective wheelbase must be at least 12.0 feet (3.6 m) a set of pivoting tandem bogey wheels at the front of the machine and at the rear wheels that travel and track in the fresh cut pavement must be provided

§ The center of the grinding head must not be further than 3.0 feet (0.9 m) forward from the center of the back wheels

§ Must be configured such that it does not encroach on traffic movement outside of the work area in adjacent lanes

§ Must be designed to remove all grinding residue; grinding residue is not permitted to flow across lanes being used by the traveling public

Requirements for surface measuring equipment (profiler):

§ A non-contact surface measuring device conforming to Supplemental Specification 1058 along with software must be to develop an IRI.

§ All necessary supplies must be provided to fully operate and graph the smoothness test results on the diamond ground pavement.

Contractors doing diamond grinding work use water trucks to provide water to the grinding heads of each grinder to cool the diamond blades.

Construction (257.03)

The plans will designate the areas to be diamond ground. Bridge decks, bridge approach slabs and roadway shoulders are not normally diamond ground unless indicated on the plans or required to provide drainage. Diamond grinding must eliminate crack or joint faults while providing positive lateral drainage by maintaining a constant cross-slope between grinding limits in each lane. Adjacent ramp lane grinding must be transitioned as required from the mainline edge to provide positive drainage and an acceptable riding surface.

The diamond grinding operation must result in pavement that conforms to the typical cross-section and the requirements specified for the final surface finish. It is the intention of this specification that faulting at joints and at cracks be eliminated and the overall riding characteristics restored within the limits specified. To accomplish the smoothness required, diamond grinding may not be required on 100 percent of the existing pavement surface.

In faulted pavement the rear slab will be lower than the forward slab (in the direction of traffic) creating a “step” or bump. Therefore Contractors will typically grind the pavement in the opposite direction of normal traffic flow so the “step” is cut first and the remainder of the slab can be feathered out. During initial grinding operations, the profiler must be used to test the pavement surface as soon as the concrete has been ground full lane width. This initial testing is to aid the Contractor in evaluating the grinding methods and equipment being used. Subsequent to the initial testing, the contractor must run daily profiles of each day's grinding the next working day.

All dust and residue generated as a result of grinding must be immediately removed. Dust cannot be allowed to blow across traffic lanes, into gutters or drainage structures.

Final Surface Finish

The final surface finish produced should be a longitudinal corduroy-type texture. The peaks of the ridges of this corduroy-type texture are to be approximately 1/16 inch (1.5 mm) higher than the grooves. There must be 53 to 57 evenly spaced grooves per foot (174 to 187 per meter).

Figure 257.B - Surface Texture Left by Diamond Grinding

The pavement surface must be tested by the Contractor with an approved profiler device that provides electronic copies of the pavement profiles compatible with ProVAL software. The contractor must produce a riding surface that does not exceed an IRI of 95 inches per mile or any localized surface deviations in excess of 0.4 inches in 25 feet.

The Engineer is to witness testing of the pavement’s wheel paths. Wheel paths are to be located 3 feet (0.9 m) measured transversely inside all lane edges and parallel to the centerline. The profiler is to be maintained at the wheel path at all times when testing the pavement.

Figure 257.C - Profile Measuring Device

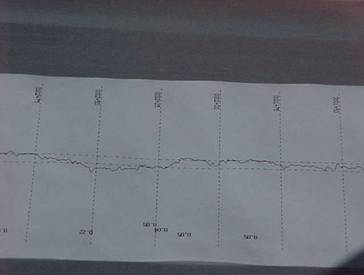

Figure 257.D - Typical Profile Trace

The Contractor must regrind any 0.10 mile section of pavement with an IRI greater than 95 inches per mile.

The contractor must provide traffic control and survey stationing necessary for all profiling. Profile measuring equipment is to stop within 1 foot (0.3m) of any existing pavement not ground, any pressure relief joint or any approach slab to a bridge.

Inspection should include spot testing the pavement to verify that transverse joints and cracks are flush with the adjacent pavement. If opposite sides of a joint or crack are within 1/16 inch of each other, it is considered flush. The cross slope should be checked with a 12-foot straightedge for deviations greater than ¼ inch. Straightedge requirements do not apply to areas that have not been ground.

Method of Measurement (257.05)

Measure pavement grinding by the square yard (square meter) of pavement ground and accepted. The quantity of pavement grinding will be determined by multiplying the width specified on the plan by the total length of the finished pavement surface measured in the field, excluding bridge decks, approach slabs and other areas designated by the Engineer.

Basis of Payment (257.06)

Payment is full compensation for furnishing all labor, materials, tools, equipment and incidentals for doing all work involved in grinding the existing surface, removing residue, cleaning the pavement, and testing with a profiler conforming to the plans and specifications.

Documentation Requirements - 257 Diamond Grinding Portland Cement Concrete Pavement

1. Check and document pavement grinding equipment prior to use to assure compliance as to width of diamond grinding head, number of grooves per foot, vacuum system, etc.

2. Check and document pavement smoothness testing equipment for compliance. Obtain ODOT certification of the equipment from the contractor.

3. Perform and document spot testing of ground pavement for surface tolerances.

4. Obtain and document profiling test results.

5. Measure length of ground pavement and use the plan width to calculate area for pay.

6. Document area calculations on CA-D-3A, CA-D-3B, or other approved form.