450

RIGID PAVEMENT

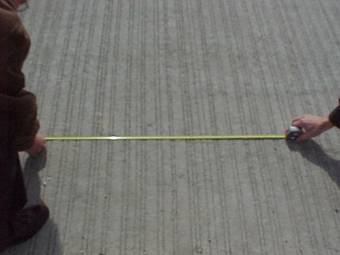

Fine Grading of Subgrade or Subbase (451.05 A and B)

Placing Reinforcement (451.07)

Documentation Requirements – 451 Reinforced Portland Cement Concrete Pavement

Portland cement concrete pavement must be constructed so that it provides a smooth-riding surface satisfactory to the traveling public and is durable when subjected to natural weathering, traffic abrasion, and chemicals used for snow and ice control. It must be capable of sustaining the traffic that it is intended to carry and be of sufficient skid resistance to eliminate slippery conditions when wet.

While the quality of the riding surface is the chief construction element by which the public either approves or condemns a pavement, this element is not more important than durability and structural strength. All desirable elements of a good pavement are a product of the workmanship of the Contractor and the engineering and inspection personnel assigned to the work.

Every step of construction, from the preparation of the subgrade and base through concrete curing and opening to traffic, has a definite effect on the rideability, durability, and structural integrity of the finished pavement.

451

Reinforced Portland Cement Concrete Pavement

Description

(451.01)

This item includes the construction of a Portland cement concrete pavement that contains reinforcing steel

Materials

(451.02)

Concrete

The concrete specified for use in reinforced Portland cement concrete pavement is Class C concrete as defined in Item 499 (Table 499.03-3). The Contractor may provide Class C concrete with one of three proportioning options specified in 499.04. If Class C with Proportioning Option 1 or Option 3 is selected, they can only be used between April 1 and October 15, unless authorized by the Director. These options allow the use of fly ash or ground granulated blast furnace slag respectively, which slows the strength gain of the concrete This characteristic is desirable during hot weather but is not desirable during cool months.

The coarse and fine aggregate used in the Class C concrete for exposed concrete pavements (Item 451 and 452) have additional requirements found in 703.02.A. The fine aggregate used in the concrete must be natural sand; therefore, sand manufactured from stone is not permitted. Coarse aggregate must be provided in accordance with 703.13 in addition to the requirements of 703.02.

Coarse Aggregate

In addition to the requirements of 703.02, the following aggregate requirements apply per 703.13.

Where gravel, crushed ACBFS, or limestone is selected and the total combined quantity of the listed items is greater than 10,000 square yards (8000 m2), the coarse aggregate must be No. 57 or 67 size. If the total combined quantity of the listed items is less than 10,000 square yards (8000 m2), the coarse aggregate must be one of the following sizes: No. 7, 78, 8, 57, or 67. If gravel or limestone No. 57 or 67 size is used in either of the above cases, the coarse aggregate must meet 703.02 and must be tested according to ASTM C 666, Procedure B.

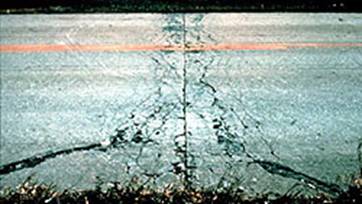

Freeze-thaw resistance testing is required for all coarse aggregate used in 451 to help eliminate the concrete pavement’s potential for D-cracking.

D-cracking is cracking caused by freeze-thaw deterioration of the aggregate within the concrete. This type of cracking can be observed as early as 7 to 10 years after construction of concrete pavement. D-cracks are closely spaced cracks parallel to transverse and longitudinal joints which multiply outward from the joints toward the center of the pavement panel. D-cracking is a function of the pore properties of certain types of aggregate particles and the environment in which the pavement is placed. Due to the natural accumulation of water under pavements in the base and subbase layers, the aggregate may eventually become saturated. Then with freezing and thawing cycles, cracking of the concrete starts in the saturated aggregate at the bottom of the slab and progresses upward until it reaches the wearing surface. This problem can be reduced either by selecting aggregates that perform better in freeze-thaw cycles or, where marginal aggregates must be used, by reducing the maximum particle size. Also, installation of effective drainage systems for carrying free water out from under the pavement may be helpful.

D-cracking in Portland Cement Concrete Pavement

Joint Sealer

Expansion joint sealer must be a 705.04 hot-applied joint sealer conforming to ASTM D 6690, Type II.

Curing materials

705.05, 705.06, 705.07 Type 2

These curing materials are burlap cloth, sheet-curing materials, and liquid membrane-forming compounds. The liquid membrane-forming compounds used on the project must be on the Department’s Qualified Products List.

Tie Bar Steel,

Epoxy Coated

Tie bar steel used in the longitudinal joints in concrete pavement must meet the epoxy coated reinforcing steel requirements of 709.00.

Reinforcing Steel

The steel reinforcing steel must comply with 709.09, 709.10, and 709.12

Dowel Bars and

Basket Assemblies

Dowel bars and basket wires used to support the dowels at the proper position must be coated with a fusion-bonded epoxy coating conforming to AASHTO M 254 with the exceptions listed in 709.13.

Equipment

(451.03)

Reinforced Portland cement concrete pavement is placed by a series of equipment called a paving train. A paving train normally consists of a concrete spreading machine, a mesh cart, a mesh depressor, a finish paving machine, a work bridge and a cure/texture machine.

The riding qualities of a pavement depend largely on the proper operation of mechanical finishing equipment. The equipment must be in correct adjustment. It is almost impossible to use hand finishing to correct a poor surface left by the equipment. Frequent checking and minor adjustments to compensate for changing conditions, will do much to eliminate surface irregularities.

The Contractor is responsible for equipment adjustments. Department personnel are not expected to adjust or advise the Contractor on how to adjust and maintain mechanical equipment, but they are expected to observe the checking of all equipment. The Inspector should be able to recognize when such equipment is out of adjustment or is not coordinated with the balance of the paving train. The following information on spreaders and finishing equipment is given to provide some knowledge on the operation of the equipment.

General Equipment

Requirements

The equipment used must be self-propelled spreading and finishing machines that are capable of consolidating and finishing the concrete; and producing a finished surface meeting the requirements specified. The specifications give the Contractor the option of using slip-form or fixed-form pavement construction methods.

Vibrators are used for the full width and depth of the concrete slabs to provide consolidation of the fresh concrete. They must be internal type, using a tube or multiple spuds. Internal means the vibrators must be immersed in the fresh concrete. External vibration is not allowed. Vibrators may be attached to the spreader or the finishing machine; or may be mounted on a separate carriage. They must not come in contact with the joint load transfer devices, subgrade, reinforcing mesh or side forms. Multiple spuds should not be spaced further apart than 2 1/2 feet (0.76 m). Therefore, a minimum of 10 spuds is required for a full 24 feet (7.2 meter) width paving.

Internal vibrators must operate at frequency of 7,000 to 11,000 impulses per minute. The vibrators should be connected to an electronic monitoring device equipped with an automatic recorder. The monitoring device should display the operating frequency of each internal vibrator. The readout display should be located near the paving operator’s controls and must operate continuously when paving and display all vibrator frequencies with manual or automatic sequencing between individual vibrators. The automatic recorder must record the following information each 25 feet (8 m) of paving or every 5-minute time interval:

· the time of day

· station location

· paving machine track speed

· the frequency of each vibrator

If the monitoring system is not equipped with an automatic recorder, the contractor must manually record the above information every 30 minutes. The Contractor must provide a record of the data to the Engineer each paving day.

Vibration is required for all concrete pavements. Small irregular areas require vibration by hand-held or machine-mounted equipment to assure that adequate consolidation for the full depth and width is achieved without segregation.

Vibrators must be connected such that they turn off when the machine on which they are mounted stops.

Transit Mix and

Central Mix Equipment

Concrete plants and hauling units must be checked for proper condition prior to paving operations, and at regular intervals during paving. Water and admixture metering devices should be checked to assure proper calibration within specified tolerances.

Transit Mix Trucks used for Concrete Delivery

Transit mixers should be checked to determine that the counters are functioning properly. After having been mixed for not less than 70 revolutions at mixing speed, the mixer should contain concrete of uniform consistency and be able to discharge the batch without segregation. Since this determines acceptability, mixers that do not perform in this manner should not be used, and discontinued if encountered. Sources of trouble are badly-worn mixing blades and leaky valves which prevent mixers from producing uniform concrete. They should not be used until corrected.

Non-Agitation Concrete Delivery Units - Dump-Crete Truck

Non-Agitation Concrete Delivery Units Dump Truck

Central mix plants should be checked to see that the mixer drum is capable of uniformly mixing and discharging the large volume of concrete. During paving, the Contractor or ready mix supplier must keep mixer blades free from concrete build up and excessive wear.

When the concrete is transported to the paving site in dump trucks or other non-agitating units, check the bodies to see that they are water-tight and free of objectionable corners or internal ribs where concrete may accumulate. Canvas covers to shield concrete from sun and wind shall be provided when required by the Engineer.

Concrete Batch

Plants

Aggregate stockpiles should be placed on areas which are paved, prepared by using sheet metal, wood plank, etc., or they may be placed directly on the ground. When building stockpiles on existing ground, the area should be firm, cleaned of foreign material, and shaped to provide drainage. No aggregate is to be removed from the stockpile within one foot of the ground until the final clean up. Aggregate within this area should be processed to meet specifications before permitting its use.

Stockpiles should be built in such a manner that different types or sizes of aggregate do not become mixed and the aggregate does not become segregated.

In building the stockpiles of coarse aggregate, exercise continual care to prevent segregation through improper handling. A clam bucket operated by a crane of sufficient size so that the center of the pile can be reached from the edge is best for this work. In depositing the aggregate, the bucket should be lowered close to the level where the aggregate is to be deposited before releasing the aggregate. This prevents the larger aggregate from rolling to the bottom of the pile causing segregation. As the pile increases in height, each layer of aggregate should be benched back to form tiers that will help limit rolling and segregation.

Other equipment may be used in conjunction with a clam bucket. If the Contractor uses front-end loaders to build the pile, they must have clean rubber tires. As with the clam bucket, the drop should be as short as possible when depositing the aggregate. Once on the pile, the front-end loader should not be permitted to move on and off of the pile as this may cause contamination.

Pushing of large aggregate with a bulldozer is not permitted, as this causes segregation. Use of steel treads on the pile is not permitted as they tend to crush the aggregate.

Small aggregate does not segregate as easily as large aggregate because the smaller pieces are less likely to roll down the side of the pile.

Any operation which might result in segregation, degradation, or contamination is not permitted. When these conditions appear evident, run a gradation test and, if substantiated, adjust the operation.

Materials should be placed in the batch plant bins by dumping into the middle of the bin with as short of a drop as possible. Keeping the drop to a minimum reduces the chance for segregation in handling aggregate, as well as in handling concrete.

The Specifications require that concrete materials be measured by weight. The scales shall be checked for accuracy with standard test weights as outlined in Item 499.

Fixed Form

Construction (451.03.A)

This construction method requires that the Contractor furnish equipment that will spread, screed, and consolidate concrete using one or more machines operating on previously placed side forms. There must be enough equipment with capacity to perform the work at a rate equal to the concrete delivery rate. The equipment must uniformly distribute and consolidate the concrete without segregation.

The equipment must either operate on two side forms, on an adjacent lane and one side form, or on two adjacent lanes as necessary. When operating the equipment on adjacent lanes, the adjacent lanes must be protected from damage from the equipment.

Forms for use on ODOT projects must meet the following requirements:

· made of steel

· straight and must not be less than 10 feet (3 m ) in length

· have a depth equal to the pavement thickness specified

· have a horizontal joint and base width equal to the depth of the forms

· forms that are bent or damaged are not permitted

Sections of Steel Concrete Paving Forms

Fixed Forms in Place Ready for Paving

Forms must be cleaned and oiled each time they are used. If the radius of the pavement edge is 100 feet (30 m) or less, flexible or curved forms may be used as approved by the Engineer.

The Contractor must provide methods and devices that securely set forms and withstand paving equipment operation. Built up forms must not be used unless constructing less than 2,000 square yards (1,650 square meters) of pavement for the entire project. All forms must have adequate joint locks to tightly join the ends of abutting sections together.

Transverse

Finishing Machines for Fixed Form Construction

The transverse finishing machine should first be checked for its operating condition. The bearings, especially those of the cranks actuating the oscillating screeds, should fit snugly so that the screed reverses direction without slap (which would rack the forms).

The end plates that slide on the forms should be inspected for wear and reversed or replaced if necessary. The screed should be checked for straightness or crown if one is required. Perform this check by placing a block on the forms under each end of the screeds and stretching wires at both front and back across from form to form. Check the crown by measuring the offsets from the wire to the screed. Adjusting bolts can be loosened or tightened to secure proper adjustment.

The exact tilt required in each screed cannot be determined until construction begins. However, at the start of paving operations, the front edge of the forward screed should be titled about 3/16 inch (5mm) and the rear screed set level. Adjustments can be made readily by end bolts provided for this purpose.

Springs are used as shock absorbers to prevent slap at the end of the stroke. These should be checked to insure that they are in compression at all times. The screed lift chains must be long enough so that they are not tight at the end of the stroke; otherwise, the screed will be lifted off the forms at every oscillation.

Finally, the wheel scrapers should be tightened so that they will be sure to keep the wheels clean.

Operation of

Transverse Finishing Machine

The work of the transverse screed is an intermediate step in the process between placing and distribution of the concrete and the final mechanical finishing. The work performed by the screed should be as nearly complete as possible, so that smoothing and floating is the only operation required by any following equipment.

As the transverse screed begins work, the concrete before it must be distributed to approximately the correct surface level, either by mechanical concrete spreaders or by hand methods. The requirements for correct transverse screed operation are the same regardless of the method of prior distribution, except that local grading by hand work will be more irregular and will require more care in the screeding operation.

The transverse screed must leave the surface with a uniform texture and a uniform, correct elevation for final finishing. Good finish cannot be obtained if the screed does not perform this function. Deep or irregular corrugations behind the screed indicate improper operation.

Satisfactory results depend upon several critical factors. These factors must be considered at all times, and variations in the adjustments or in the operation of the screed must be made, as occasion demands, to keep the factors always in balance.

The head of concrete carried in front of the forward screed must be maintained at a uniform height, about 4 to 10 inches (100 to 250 mm), and in uniform quantity across the full width of the lane.

The concrete head carried in front of the rear screed must be uniform and about 2 to 4 inches (50 to 100 mm) high. The material being moved ahead by the rear screed should roll, not flow or tear, and the mix and timing of operations must be controlled to satisfy this requirement.

The height and tilt of the screeds must be adjusted to compact the particular mix being used and to permit a uniform amount of surge.

The traction speed, screed speed, and length of screed stroke are controlled independently. These must be combined in the proper relation to obtain optimum results. As conditions on the project vary, these relationships should be varied to produce a consistent surface.

The forms and wheels must be kept clean. If the wheels ride on an irregular surface, the concrete will show corresponding roughness. The screeds must be kept clean, so that they do not leave streaks in the concrete and do not drop lumps of hardened concrete on the fresh surface.

The amount of concrete being carried ahead of the screeds (both forward and rear) controls the amount of surge past the screeds for any given mix. If the head of concrete is too high, an excess will pass under the screed and leave an overload for following equipment. If there is a deficiency of concrete at any point in front of the screed, a low spot develops. If the head varies continually, the surge will also vary and a wavy or rough surface will be left. Therefore, a uniform roll of concrete must be maintained along the front edge of the screeds to provide a uniform amount of surge. At the beginning of a day’s work, a small amount of concrete should be placed in front of the forward screed to provide a working supply for filling in low areas. This accumulation should not be allowed to build up as the work progresses, but should be maintained uniformly. If excess builds up, the excess should be screeded off or a second pass made.

The Inspector should insist on coordination of distribution and transverse screeding to obtain continuous, acceptable results. The forward screed should compact the concrete level with the top of the form allowing for a very small amount of settlement that usually occurs before the following finisher passes. The difference in the requirements at the two screeds accounts for the difference in the size load each should carry.

Inspectors on transverse screeding work must remember that the finishing machine is not intended for heavy duty. The surface left by this work must be uniform and satisfactory. The transverse screed is capable of meeting these requirements. The Inspector should insist that the operator make full use of the machine’s capabilities in order to obtain a complete and proper integration with the entire paving process.

If one pass of the screed does not result in satisfactory surface conditions, a second pass is necessary. It is preferable that preceding operations be controlled so that a second pass is not required at intermittent points. The Contractor may elect to use two screeds or to pass over the entire area twice with one machine. Different amounts of screeding will result in variable surface conditions and are to be discouraged.

Screeds should be operated with the screed wearing plates working directly on the forms. A straight screed with no tilt results in a concrete surface at or below form level, except for surge. Adjustments in screed elevation and tilt may be required to work certain mixes properly. If the concrete mix is extremely stiff, the screeds normally will tear the surface and leave insufficient mortar for finishing. Under these conditions, the front or first screed should be tilted so that the forward edge is raised slightly. This compacts the concrete as the screed passes and forces a small amount of mortar to the surface. Extremely stiff mixes usually demonstrate an absence of surge which, with combined tearing, leaves the surface below the top of forms. The center of the screed then should be raised slightly by adjusting end screed hanger bolts, leaving the end plates to work on the forms with the remainder of the screed raised. This permits the required amount of concrete to pass the forward screed. The rear screed always should be straight along the rear edge and work directly on the forms.

The amount of tilt of the screeds must be worked out for the particular job conditions. As a starting guide, the following information will be of assistance. With standard Portland cements and with air-entrained concrete of relatively stiff consistency, less than 2-inch (50 mm) slump, the forward screed will likely require a tilt of 1/4 inch (6 mm) or less and the rear screed a tilt of 1/16 inch (0 to 2 mm).

The combination of traction speed and screed motion depends on the concrete mix and consistency, and on the grade or super elevation of the pavement. With stiff mixes, the screed speed should be rapid with a long stroke and the traction should be slow in comparison to more workable mixes. This aids in compaction and in providing enough mortar at the surface for finishing. With more fluid mixes, the screed action should be decreased; both in speed and length, and the traction speed should be increased. This will prevent over working or excessive agitation of the concrete, which might cause flowing to the low side of the forms, excessive surge past the screeds, or a pooling of wet mortar on the top. The relation of traction and screed speeds is very important. In most machines, the controls are independent and the proper combination can be made by trial without any difficulty. A change in speed of either screed or traction requires only shifting of a lever. The change of length of screed stroke requires a work stoppage and readjustment of the screed drive, but this change should not be required very often unless control of the concrete mix is poor. Poor control of the concrete mix should not be tolerated.

The screed wearing plates are rubbing continuously on the forms or on completed concrete lanes. They are made of abrasion-resisting steel, but may wear rapidly. As they wear, they have the effect of lowering the entire center portion of the screed by the amount of wear. Furthermore, the wear may not be the same for the full length of screed stroke, and may change the strike-off elevation of the screed. They should be checked at the beginning of each job. Adjustments for up to 1/8 inch (3 mm) in wear can be taken care of by adjusting the screed bolts. The plates should be replaced when wear exceeds this amount.

Exercise care when operating the finishing machine over expansion joints to avoid displacing or damaging the preformed expansion material. Any method of operation that does not interfere with the expansion material will be permitted.

Combination Float

Finisher

The combination float finisher is commonly used to provide the final mechanical finish on a pavement. The machine consists of two screeds and a float and is designed for use on a 24-foot (7.2 m) pavement.

The front screed of the machine is a conventional reciprocating screed that rides the forms. The rear screed and float, however, are suspended from an approximately 16 foot (4.9 m) beam platform and do not receive any support from the forms. The elevation of both the rear screed and the float is determined by adjustment of the hangers that connect them to the platform. As a result, variations in forms do not significantly affect the plane of operation of either the rear screed or float. The key to smooth finishing with this machine is the rear screed since it is the final screeding tool and operates from a 16 foot (4.9 m) straightedge essentially free from influence of deviations in the forms.

Spring-loaded shoes are fastened to both ends of the rear screed to keep the screed in contact with the forms. The springs are sufficiently strong so that the rails will be kept clean, but not so strong that they will cause the screed to raise when an undetected highpoint in the forms is being traversed.

The float does not oscillate but moves forward with the machine providing a smooth trowelled surface. It is approximately 30 inches (0.7 m) in length and rides on the slab between the forms. Both of the screeds and the float are provided with devices which permit rapid changes in crown. These devices make it possible to change crown at superelevated sections without delay.

Operation of

Combination Float Finisher

The combination float finisher serves both as a conventional transverse and longitudinal finisher. The transverse screeding is accomplished through the two screeds (front and rear) and the longitudinal finishing by the suspended finishing pan that rides on the slab surface.

Several details must be adhered to closely in order to obtain the best possible finish when the machine is used for the final mechanical finishing operations. These items are described in the following paragraphs.

The concrete must be accurately fed to the machine. Better results are obtained when spreaders and auxiliary screeds (when used), operating ahead of the machine, leave just enough concrete so that a uniform roll of 4 to 6 inches (100 to 150 mm) is carried on the front screed. When this condition does not exist, the equipment operating ahead of the float finisher should be adjusted so that such a concrete roll is obtained.

The screeds and float must be set accurately. Both front and rear screeds should be set flat. When the front screed is flat and carries a 4 to 6 inch (100 to 150 mm) roll, it passes sufficient concrete to form about a 2-inch (50 mm) roll on the rear screed. When this 2-inch (50 mm) roll reduces in size, fresh material should be carried back and placed to obtain a uniform roll. It is essential to keep the roll in front of the rear screed uniform for optimum results.

The rear screed cuts off any excess concrete and leaves the pavement surface at the desired crown and grade. When set to proper crown without tilt, the float just makes contact with the surface and trowels it smooth and free of screed marks. Occasionally, it is desirable to leave the front of the float about 1/16 inch (2 mm) high when greater compaction is desirable. This practice, however, generally leaves deeper transverse marks than are considered desirable.

The finishing machine is designed primarily for a one-pass operation. If all operations prior to the pass of the machine are as they should be, it is rarely necessary to make more than one finishing pass. If the forward speed is adjusted properly, the machine moves forward at a uniform rate, eliminating frequent stops that cause variations in the surface. It is true with this machine, as with other types of finishing equipment, that continuous operation provides smoother pavement.

The machine must be kept clean. The bottoms of the screeds and the pan must be absolutely smooth. Accumulations of hardened concrete (or oil and grease) that might drop on the pavement must be cleaned off continually. The machine should be cleaned thoroughly every day.

Slip Form

Construction (451.03.B)

This method of construction permits pavement placement without the use of fixed side forms. In lieu of forms, the paving machine vibrates, tamps, compresses, and strikes off the concrete within the machine’s moving forms, and extrudes the consolidated concrete slab. Consolidation is such that the vertical sides of the slab retain their shape and position after leaving the paving machine. Trailing side forms are needed only to protect the slab edges during hand straight-edging operations. The slip form paver/finishing machine has three main components: augers, vibrators, and a profile pan. The augers spread the concrete across the width of the area to be paved. The vibrators provide consolidation of the concrete as it passes under the paver. The profile pan, located at the rear of the paver, trims the concrete to the proper elevation and provides a smooth surface.

The base must be constructed as outlined in the specifications. Stability of the base is critical for slip form construction. The base must be graded to the plan elevation by a properly designed machine. The track area for the paving train may be brought to grade using a form grader, with a subgrader on crawlers used to grade the area under the pavement. An automatic subgrader operating from a preset grade line is ideal for slip form construction and does not require the use of a form grader.

Stabilization in the paving machine track area to provide traction is permissible, provided the area is scarified after pavement construction, to avoid interference with lateral drainage of the subbase. Any method of stabilization proposed by the Contractor must be approved by the Engineer.

An approved slip form paving machine or combination of paving machines must be used to spread, consolidate, screed, and finish the concrete in one pass. The machine(s) must consolidate the full width and depth of pavement being placed, to provide a dense homogeneous pavement slab, requiring a minimum of hand finishing. Two machines may be used with the leading machine striking off the bottom course for placement of the mesh. The width of the bottom course may be 6 inches (150 mm) narrower than plan width so as not to interfere with the second paving machine.

Slip Form Construction

Preset grade lines are required for slip form paving equipment to assure acceptable riding quality of the pavement. Paving equipment must have controls that trace the grade line and automatically adjust the screeds. String lines offset from and parallel with the edge of pavement are used most often. Sensors on the paver follow the string line and automatically adjust the screed.

The use of string lines will not assure riding quality. All lines, grades, and controls should be frequently checked to avoid obvious errors. The electronic controls of the slip form paving equipment are not capable of sensing grading errors and will therefore duplicate those errors in the pavement surface. When a string line is used, the string line should be supported at intervals that eliminate sagging of the string under its own weight. Supports every 25 feet (8 m) produce the most desirable results. In addition to the intervals between supports, the stringline tension must also be taut enough that excessive sag does not occur.

The concrete slump should not exceed 3 inches (75 mm) and the nominal range is 1 to 3 inches per 499. If the slump exceeds 3 inches (75 mm), the edges may be subject to settlement after the forms have passed. Slump less than about 1-1/2 inches (40 mm) may result in an open textured surface requiring excessive hand finishing. Therefore, the slump should be maintained between 1-1/2 and 3 inches (40 and 75 mm) for best results.

Good construction results are achieved by operating the paving machine with a continuous forward motion with a minimum of starting and stopping. When the paving machine stops, all vibrating, tamping and oscillating elements must stop also.

The slip form machine must not be used like a dozer to push large quantities of concrete piles out in front of it. Therefore, some means of depositing and striking off the concrete must be used to permit smooth uninterrupted operation of the paving machine(s). The use of spreader boxes, a concrete spreader, or any technique that provides a uniform distribution of concrete is permissible.

At the end of the day’s production, pavement at construction joints may be reduced approximately 2 inches (50 mm) in overall width. This allows the Contractor to use an insert just inside each moving side form so that the paving machine(s) can be positioned at the joint when production is resumed. The trailing side forms do not bind and spall the slab edges when this leeway is provided on each side.

Inspection of slip form paving should include checking the pavement edges. Since no forms are used to screed against or to hold the edge in place, the edge can slump downward or tilt out. A straightedge can be placed perpendicular to the edge to check transversely. In addition, the straightedge can be placed longitudinally at the pavement edge to check in that direction. Areas that do not meet the tolerance must be corrected while the concrete is plastic.

Where pavement will be placed against an edge, the pavement must not vary more than 1/4 inch (6 mm) below the typical section.

Where pavement will not be placed against an edge ( outside edge) the pavement must not vary more than 1/2 inch (13 mm) from the typical section.

All pavement edges must be nearly vertical with no projections or keyways exceeding 1/2 inch (13 mm). If edge projections exceed 1/2 inch (13 mm) concrete must be removed by hand methods and the edge should be troweled smooth.

Setting Forms

Forms are a potential source of trouble because they serve as the “tracks” for the paving equipment in addition to serving as forms for the concrete. Since developments in paving equipment have provided heavier equipment, the forms play an increasingly important role in the construction of smooth pavements.

Before any forms are set on a project, they must be inspected to see that they comply with specification requirements. In addition, they must have sufficient pin pockets for setting securely so that they will withstand the operation of the paving equipment. Forms are to be set such that that they do not vary more than 1/8 inch in 10 feet (3 mm in 3 m) on the top face; or more than 1/4 inch in 10 feet (6 mm in 3 m) on the vertical face. If they cannot be reset or repaired to meet this tolerance they cannot be used. Forms are reused continuously. Therefore, inspection of forms must be continuous. Any time forms are found out of tolerance, they must be rejected. Forms that are rejected should be marked so they are not incorporated into the work.

Forms are Set in Position and Pinned to the Base

Forms are to be set true to line and grade on a thoroughly compacted base with uniform bearing throughout their entire length and width. Using loose earth pebbles or other shims to bring forms to the required grade is not permitted. Whenever adequate and uniform form support is not obtained, the forms must be removed, the base corrected and compacted, and the forms reset. At least 3 form pins are to be used in each 10-foot (3-meter) length. These pins must be long enough to hold the form in position during the placing and finishing operations.

Pin keys must be straight and free-moving in the pockets and capable of holding the forms tight against the pins. The joint locks must not be bent or worn and must be capable of holding the ends of the forms in true alignment. The pins and locks are checked when the forms are set but should be rechecked just prior to placing of concrete and tightened if necessary. Make a final visual check at the same time to insure forms are at proper line and grade. Smooth riding pavement with good surface finish is extremely difficult to obtain with poorly aligned and set forms.

The forms are to be cleaned and oiled prior to placing of the concrete. When hook bolts or wiggle bolts are fastened to the forms, the forms must be oiled prior to placing of these units.

Fine

Grading of Subgrade or Subbase (451.05 A and B)

After the embankment has been placed and compacted the subgrade is brought to the required grade, cross section, and density in accordance with 204. Base material is provided by plan for all concrete pavements with only a few exceptions. The typical plan section indicates the depth and width of compacted base materials. Generally base material is 304 Aggregate Base and must be placed, shaped, and compacted in accordance with that specification. Fine grading of the base material should be done in advance of the concrete paving operation to allow the Engineer to check the established grade for conformance to the plan elevation. After the grade has been checked and accepted, no further disturbance of the base material is allowed.

Fixed Form

Construction and Slip Form Construction

The surface of the base material is left approximately 1 inch (25 mm) above grade after compaction has been completed to the required density. Then, after forms have been set to grade for form paving or the string line is set for slip form construction, the slight excess is removed with a subgrade planer (subgrader). The fine grading operation should result in a slight removal so that the trimmed surface is compacted thoroughly without low areas. Low areas require the addition of material, compacting, and regrading resulting in a delay in progress of fine grading.

When automatic subgraders are used, they will precede the setting of forms. Grade will be maintained from a preset string line that will be parallel to the grade line. After final trimming the surface will be treated the same as for conventionally graded base.

Loose base material windrowed along the inside of the forms cannot be removed by machine so removal of this material by use of a shovel is necessary. This shall be done before re-compacting.

The trimmed surface left by the subgrader should be compacted to restore surface density. This rolling operation also smoothes the surface and reduces the friction between the base and the pavement.

For fine grading between forms the resulting base surface must be checked using a multiple pin template operated on the forms. The template must be operated behind the subgrader and roller. Any high or low spots encountered shall be corrected immediately, then rerolled and rechecked before continuing. Where the subgrader is operated on a string line, the grade will be checked based on the grade stakes for the pavement. The Inspector should record the limiting stations of the area checked and conformance to the specification requirements in project records.

The subgrader is usually one of the heaviest pieces of equipment operating on the forms. Therefore, this is an opportune time for the Inspector to observe the forms for excess movement or displacement. Areas where movement or displacement is noticed should be rechecked for compliance with requirements before placing concrete.

Moisture is controlled by spraying the base prior to fine grading, preferably in the late afternoon of the day before fine grading. This provides the uniform moisture distribution necessary for density. After removal of excess material during fine grading, moisture is present for the final surface compaction.

It is good practice to recheck the alignment and grade of forms, the form locks, and the pin keys after fine grading. Some Contractors assign employees to this job. The Inspector should check these items regardless of the Contractor’s operation to assure that any irregularities have been corrected. Since the paving equipment relies on the forms for support, it cannot be expected to produce a quality-riding surface when yielding or improperly set forms are encountered.

Placing Concrete (451.06)

Prior to placing concrete, the subbase must be thoroughly moistened with water. This keeps the subbase material from absorbing water from the plastic concrete affecting its workability and decreasing its set up time. Different moisture levels throughout the depth of concrete can build in stresses that lead to cracking.

The concrete must be placed as close to the paving and finishing operation as possible to limit rehandling. Excessive handling of plastic concrete can reduce the air entrainment and thus long term durability of the pavement.

Even distribution of concrete on the base, or in each course being placed, is the first step toward an acceptable job. The most even distribution in initial placing results in minimum variation in final surface settlement. If concrete is deposited in piles, or windrows, unequal consolidation may take place before finishing operation are begun. This never will be overcome throughout the finishing procedure and can be the cause of unequal settlement and rough surfaces after finishing has been completed. In the case of transmit mixer or dump truck delivery, use discharging methods that spread each batch as evenly as possible. Better results are obtained when a hopper-type spreader is used with either transit mixer or dump truck delivery.

Workers should not walk in the concrete unless they are wearing clean boots that do not have dirt, earth, clumps, or other foreign matter on them.

Concrete must not be allowed to displace dowel bar assemblies or expansion joints.

A separate concrete spreader is required when the width of

pavement being placed in one operation is 12 feet (3.6 meters) or more and the

area of any given width exceeds 10,000 square yards (8,300 square

meters). Concrete spreaders must be separate, standard

manufacture, self-propelled machines that receives concrete into a hopper

adjacent to the area to be paved and delivers the concrete in front of the

slipform paver and uniformly spreads the concrete at the proper thickness for

the full width being paved. Spreaders

must be adjusted to leave the proper amount of concrete for the required slab

thickness. The amount of concrete

left is determined by the elevation of a strike-off plate located behind the

screw augers, paddle, or hopper that distributes the concrete.

Concrete Spreader

The elevation of the bottom of the strike-off plate in relation to the top of the forms is shown on an indicator that is visible to the operator. The equipment should be checked to make sure that the indicator shows zero when the bottom of the strike-off is exactly even with the top of the forms.

Concrete spreaders are powerful pieces of equipment that will handle heavy accumulations of concrete. However, this is not a reason to permit improper distribution. When a slipform paver is equipped with a dowel bar inserter the separate spreader requirement may be waived provided the slipform paver is capable of spreading, consolidating, screeding, and float finishing the freshly placed concrete. The contractor should provide the Engineer documentation that the slipform paver will meet this specification.

The initial placing of the concrete should be just enough so that a slight excess is carried ahead of the spreader as it levels the concrete to a uniform surface. (If a spreader is not required, the concrete can be spread and leveled easily with shovels.) Unless this is done there will be an irregular surge past the strike-off of the spreader or past the finishing screed. This necessitates excessive manipulation of the surface in order to obtain specified smoothness requirements. Excessive manipulation tends to alter the quality, durability, and wear resistance of the finished pavement.

Concrete should not be mixed, placed or finished after dark without operating an adequate and approved lighting system.

When the air temperature is 35 °F (2 °C) or below, the concrete temperature must be between 50 and 80 °F (10 and 27 °C) at the point of placement.

When the air temperature is greater than 35 °F (2 °C), the concrete temperature cannot exceed 90 °F (32 °C).

Concrete cannot be placed on any surface that is frozen or has frost.

Two test beams are to be made for each 7500 square yards of concrete, or fraction of 7500 square yards that is placed each day.

Concrete Running

Yield Check

The running yield of concrete may be determined at any time during concrete paving and can provide an easy, accurate method of checking that the proper thickness is being placed. When a constant width and thickness is placed a running yield factor in cubic yards per foot (cubic meters per meter) can be calculated. This factor is determined by calculating the amount of concrete required for one foot length (one meter) of finished pavement of the width and depth being placed. This factor is computed by using Equations 451.2 and 451.3:

Yield Factor = Width (ft) x Thickness (ft) x 1 ft

27 ft3 / yd3

Equation 451.2 – Yield Factor

Yield Factor = Width (m) x Thickness (mm) x 1 m

1000 mm / m

Equation 451.3 – Yield Factor (metric)

Example:

A contractor is placing a 24-foot wide slab that is 9 inches thick. Determine the yield factor for this cross-section. Using Equation 451.2 the following calculation results:

Yield Factor = 24 ft x (9 in/12 in/ft) x 1 ft = 0.667 yd3 per foot of length

27 ft3/yd3

Once the running yield factor has been calculated, it can be used to determine the concrete volume required for any length of slab of the same dimensions. The running yield is determined by multiplying the running yield factor by the length placed as shown in Equation 451.4.

Running Yield = (Yield Factor) x Length Placed

Equation 451.4 - Running Yield

The actual quantity used is easily computed for any length of slab by multiplying the number of batches placed by the number of cubic yards (cubic meters) per batch.

Example:

Using the yield factor determined above calculate the running yield for 4,245 linear feet of concrete pavement when 360, 8-cubic yard truckloads were used. Also determine the volume used and compare the volume used to the volume required and show which is greater. Determine the difference in volume and the percent over-run or under-run.

Running Yield = (0.667 yd³/linear ft) X (4,245 linear feet)

= 2,830 yd³ (required volume)

Volume Used = (360 batches) X (8 yd³ per truck) = 2,880 yd³

2,880 yd³ (volume used) > 2,830 yd³ (volume required)

2,880 yd³ - 2,830 yd³ = + 50 yd³ difference

(50 yd³ ÷ 2,830 yd³) x 100 % = 1.77% overrun

The quantity used may be from 1 to 3 percent greater than that required, generally due to wasting over the forms, spillage, etc. An overrun of 3% or more should be investigated to determine the cause. Overruns may be caused by several factors, including inaccurate weighing, low subgrade/base, excessive waste, etc. Similarly, an under run in concrete may be due to inaccurate weighing, high subgrade/base, insufficient width, thickness of slab, settlement of forms, etc.

Hot Weather

Construction

When high air temperatures, low humidity, and winds are encountered during concreting operations the rate that concrete hydrates (hardens) increases. High temperatures, especially when accompanied by wind and low humidity, tend to cause a rapid loss of moisture from the surface of the pavement resulting in early setting and a reduction in time allowed for finishing.

Lowering the concrete temperature to 75º F (24º C) or below will help offset the effects of high ambient temperatures. Selection of a cool water supply is the most effective means of lowering the mix temperature. Sprinkling of coarse aggregate stockpiles for moisture control also aids in controlling the mix temperature.

It is a good practice when form paving, to maintain the slump of the concrete near the top limit during hot weather. Increasing the slump will help delay hydration, thereby making more time available for the finishing operations.

During hot weather operations there may be a tendency to add water to the surface of the concrete to aid in finishing. This practice cannot be allowed. Using water on the surface during finishing results in an increase in the water-cement ratio and washes out the entrained air in the concrete at the surface. Both of these changes adversely affect the long term durability of the surface of the pavement. The use of the whitewash brush to sprinkle water has probably been the cause of the majority of scaling occurring in concrete surfaces.

Under extreme drying conditions caused by high temperatures coupled with low humidity and high winds, mixing water may evaporate quickly from the surface of the concrete. This water may be restored by applying a fog spray of water on the surface, provided the surface has been completely finished and will not be screeded or straightedged. This provision should be controlled carefully and should be the exception rather than the rule.

An approved Type B or D (705.12) set retarding admixture is required when the concrete temperature exceeds 75°F. Set retarders help slow down the setting time thereby providing more time for finishing. The use of this admixture will result in less slump loss and result in higher strength concrete.

Protection from

Rain

Concrete paving must not be undertaken in rainy conditions, however in the course of paving, rain can occur and the Contractor must take steps to protect the plastic concrete from damage. If the pavement is adequately protected from rain extensive corrective work can be avoided.

A roll of polyethylene sheeting on the finishing machine or the curing machine can be quickly unrolled to protect large areas of pavement. When the concrete has not been protected and has been damaged by rain, increased attention to corrective measures will be necessary to obtain durable concrete.

Concrete that has been exposed to rain will have some mortar or paste washed from the surface resulting in a “sandy” appearance along with a speckled or splattered surface pattern. If the surface has not been machine finished, it should be screeded with the machine. This screeding will eliminate the sandy texture and force grout to the surface. For a surface which has been machine finished, the machine may be used to make a single pass over the area affected, or the surface may be dragged with the burlap to remove the sand and work grout to the surface. A broom drag may have to be used for several passes to restore the surface finish. When correcting damage to newly placed concrete surfaces, the excess surface water must first be removed; NOT worked into the concrete. Cement must not be placed on the surface in an attempt to restore cement paste washed away by the rain. Such a practice is detrimental to the concrete and must not be allowed.

When a rain persists for a lengthy period, it will be necessary to remove any protective covering to finish and texture the concrete before it sets. Membrane curing should not be applied when the surface is wet and may be delayed until paving is resumed. If polyethylene sheeting is used as a covering, curing may be delayed indefinitely provided the sheeting is maintained in accordance with the specifications. However, membrane curing should eventually be applied to provide a surface uniform in appearance.

If rain damages the curing membrane, the surface should be re-sprayed after the excess water has dissipated to restore the impervious covering and retain moisture necessary for curing.

If, for any reason, measures taken by the Contractor to produce a surface that meets specifications are unsuccessful, the affected portions of the pavement must be repaired or replaced to comply with contract requirements.

Cold Weather

Construction

During cold weather, provisions must be made to prevent concrete from freezing until it has attained adequate strength. Concrete that has been frozen prior to gaining sufficient strength may be permanently damaged; and may never achieve the design strength. Therefore, it is necessary to protect the concrete from freezing temperatures during the cure period.

The temperature of the concrete and the surrounding air directly control the rate of hardening of the concrete. As the ambient temperature decreases, the rate of hardening decreases. The rate of hardening ceases at the freezing point. If the concrete is maintained just above freezing, it will not be damaged. However, it will require a lengthy curing period before it will harden and gain sufficient strength.

The Contractor is responsible for protecting concrete during cold weather. If damage might possibly occur, the surface shall be protected by any means that prevents the concrete from freezing and retains the heat of hydration.

In order to control the rate of hardening and strength gain, it may be necessary to control the temperature of the concrete being placed and to protect the concrete thereafter to retain the heat of hydration during curing. If the air temperature is 35º F (2º C) or below when concrete is being placed, the concrete must be have a temperature from 50º to 80º F (10º C to 27º C) when placed. The Contractor is responsible for ensuring that the concrete temperature is in the required range.

If the concrete temperature is less than 50° F the mixing water or aggregates may be heated. The heated water and aggregate should be introduced into the mixer before the cement, so that the temperature is reduced before cement is added to avoid the possibility of a flash set. One further precaution is to delay the introduction of the air-entraining agent until the temperature has been reduced, because hot water tends to reduce its effectiveness.

The subgrade or base and forms must be free from frost when concrete is placed. Covering these areas usually prevents frost and avoids delays.

Any request to incorporate an accelerating admixture during cold weather construction must be submitted and approved.

Job Control Testing

and Sampling

All material being used in the production of concrete shall be sampled, tested and approved, or accepted by certification before being used. Material that has not been sampled before delivery to the project must be sampled and submitted for testing. Such material must not be used until approval has been given by the Laboratory. Sampling must be done in accordance with the specifications and as outlined in Item 499.

Concrete for use in pavements must meet the specified requirements for air, slump and yield. Tests must be conducted to check for compliance with these requirements. The test results must be within the following limits:

|

AIR |

SLUMP |

YIELD |

|

6 ± 2% |

1 – 3 inches |

± 1% |

|

8 ± 2% when using No. 8 Course Aggregate |

4 – inches maximum |

The Contractor must be notified of out of specification test results and make immediate adjustments to the mix. Production should be stopped and check tests made to confirm noncompliance of the original tests. Concrete that does not meet specification requirements must not be used unless adjustments can be made to correct the deficiency prior to incorporating it into the work. The fact that concrete has been produced and transported to the project does not justify its use unless it conforms to requirements.

Insufficient air may be corrected by the addition of an air-entraining agent and remixing the load to generate additional entrained air. Variations in yield should not be cause for rejection; however, immediate adjustments must be made in the batch weights and must be followed by additional yield tests until conformance is obtained. Slump may be increased by the addition of water provided it remains within the limits of the water-cement ratio. If slump is excessive, the concrete should not be used.

Concrete cylinders are not required for pavement concrete. However, if for some reason cylinders are desired, they should be cast from concrete obtained at the paving site and are to be made in accordance with Item 499. Cylinders are to be shipped to the Laboratory on the fourth day after casting where they are tested for compressive strength at 28 days of age.

Results of air, slump, and yield tests must be recorded on the Concrete Inspector’s Daily Report. Results of flexural tests on beams are to be recorded in the project records. Results of compression tests on cylinders (if made) will be reported by the Laboratory.

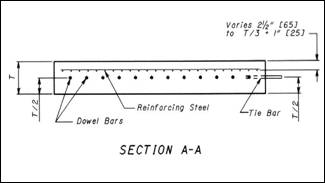

Placing Reinforcement (451.07)

Distributed steel or reinforcement used in reinforced pavement (Item 451) is generally welded wire fabric or mesh. Its principal function is to hold together the fractured faces or slabs after cracks have formed. Adequate load transmission across the crack is thus assured, and the infiltration of incompressible material into the crack is prevented or delayed. It does not increase the flexural strength of an unbroken slab. Like tiebars, steel mesh is designed to withstand tensile stresses and hold the slab together.

Mesh is usually delivered to the job in advance of paving operations and stored. It should be carefully stacked and kept clean. Before it is used, it should be inspected to see that it has not been damaged in shipment or in storage, and that it is free from dirt, oil, and mud, which will hinder the bond with the concrete. Any mesh that has been bent or has broken welds should be rejected. If the mesh is repaired, it should be rechecked before using. Mesh with rust, mill scale, or a combination of both will be considered satisfactory provided the minimum dimensions are not less than specified. Recent research indicates that tight, scaly, and pitted rust does not prevent bond, but actually improves it.

Therefore, mesh should not be rejected for rusting unless the rust is so severe that the wire dimensions are reduced to less than the minimum specified. Reinforcing mesh details for (Item 451) pavement are shown on Standard Construction Drawing BP-1.1. The longitudinal wire is designated as a W8.5 or D8.5 (MW55 or MD55) size and has a nominal diameter of 0.329 inch (8.4 mm). The longitudinal wires are to be spaced at 6 inch (150 mm) centers. A W4 or D4 (MW26 or MD26) wire is used transversely and has a nominal diameter of 0.225 inches (5.7 mm). Transverse wires are to be spaced at 12 inch (300 mm) centers. If it is suspected that the wire dimensions have been reduced, the District laboratory should be requested to check the wire dimensions with a micrometer.

Concrete Spreader with a Mesh Cart

If mesh is placed along the rough grade or the shoulder to be easily accessible during paving, it should not be done so far in advance that mud will accumulate on it. Take care to prevent the mesh from becoming badly bent.

If a mesh cart is used on the forms behind a spreader, the mesh is stacked in cart-sized piles at intervals along the grade. These stacks should be placed on wood blocks or in some manner to keep them from becoming caked with mud or soil.

The specifications allow three methods of installing reinforcing mesh. The allowable methods are:

1. Place one layer of concrete, place the mesh on top of this layer so that it is located at its final location without any further manipulation, and place the second layer of concrete on top of the mesh. If the pavement is being placed in two layers, the concrete for the base layer should be distributed uniformly on the base and then struck off by means of a mechanical spreader to the proper depth. The strike off should leave a plane surface without voids or high or low spots on which to place the mesh

2. The mesh may be supported on chairs at the correct elevation and securely anchored to the base and the concrete placed in one layer.

3. Place and spread one layer of concrete; while the concrete is still plastic, use a mesh depressor that vibrates or mechanically installs the mesh to the proper depth in the slab. This method eliminates the need for placing two courses of concrete and thereby eliminates the possibility of a plane of weakness (a cold joint) between two separately placed courses. Control of the mesh placement within the slab is more accurate than when placed between courses, based on measurements of cores removed for checking thickness requirements. Another advantage of this method is that a bulkhead can be placed readily and quickly in the event of breakdown since the concrete is placed full depth, and not in two separate courses.

Placing Two layers of Concrete

Mesh Supported on Chairs

Using a Mesh Depressor

Mesh is required to be located in the slab within the range of 2 1/2 inches to T/3 + 1 inch (64 mm to T/3 + 25 mm) below the finished concrete surface (where T is the thickness of the pavement). In its final position, reinforcing mesh must not touch either dowel bars or tie bars. Mesh must also be located such that there is 2 inches (50 mm) clearance from a longitudinal joint or pavement edge to the reinforcing wires and 12 ± 2 inches (300 ± 50 mm) from any transverse joint.

Location of Reinforcing Steel Mesh

If the mesh is bent, it should be straightened before it is placed; if it has a gradual bow, place it so the concave side is down. Workers placing steel must not track mud or dirt into the concrete.

Two types of machines have been approved for use in vibrating the mesh into position. One type consists of a grid of steel plates approximately 15 feet (4.6 m) in length and extending the full width of pavement being placed. The self-propelled machine is positioned over the mesh, stopped, the mesh depressed into the freshly placed concrete, and moved ahead to repeat the operation.

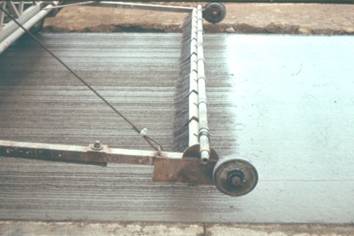

Mesh Depressors

The other type is also self-propelled and consists of long tapered longitudinal runners across the width being placed. This machine gradually depresses the mesh into position in the fresh concrete using an oscillating tamping motion while continuously moving forward.

Since there is forward movement during placing, the latter type of machine may cause movement of the mesh across transverse contraction joints when not properly adjusted. When using a machine of this type, periodic checks must be made by uncovering the mesh at joint assemblies to assure that the specified clearance of 12 ± 2 inches (305 ± 51 mm) is being maintained on each side of the center of the transverse joint. If the mesh position is found to be outside of tolerance, it should be corrected and the machine adjusted at once; or its use immediately discontinued. Production may be continued without the mesh installer by changing to the two-course method.

Both types of machines can be adjusted to control the depth of the mesh. Therefore, depth checks must be made daily to confirm that the machine is placing mesh to the required depth. Standard Construction Drawing BP-1.1 requires the mesh to be placed below the top surface of the pavement a distance of between 2 1/2 inches to T/3 + 1 inch (64 mm and T/3 plus 25 mm) where T is the thickness of the slab. When mesh depth is out of tolerance, immediate adjustments must be made by the Contractor.

The mesh is to be placed between the forms, or between the pavement edges, leaving 2 inches (50 mm) between the ends of the wires and the side forms, pavement edge, or pavement centerline. Reinforcing mesh is normally shipped in lengths of 19 feet (5.9 m) by 11 feet 8 inches (3.6 m) wide which will fit the specified joint spacing of 21 feet (6.5 m) for reinforced concrete pavement with an allowance of 12 ± 2 inches (300 ± 50 mm) from the center of each transverse joint. If shorter lengths are provided, transverse laps must be 12 inches (305 mm) and mesh sheets must be fastened at the edge of the lane and two other locations.

Usually, mesh is not fabricated for lane widths greater than 12 feet (3.6 m). Therefore, when placing pavement lanes in excess of 12 feet (3.6 m) in width it will be necessary to tie additional mesh to the standard width sheet. This is done by tying the outer longitudinal wire of adjacent sheets together. A minimum of four ties should be placed along the overlapped longitudinal wires to hold the two sections of mesh in the same plane until the concrete sets.

If the screeding operation has been done properly and the mesh placed in flat sheets and tied properly, there will be no difficulty with the steel working up into the finishing operations.

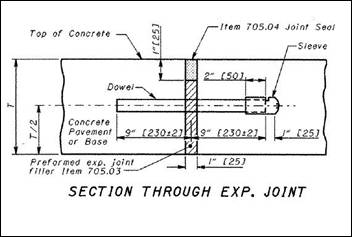

Joints (451.08)

Joints are classified as transverse and longitudinal. Transverse joints are further classified as contraction, expansion, and construction joints. Detailed instructions for joints are found in the specifications and in the standard construction drawings. See Standard Construction Drawing BP-2.1 for longitudinal joint details and BP-2.2 for transverse joint details. The Inspector should know the requirements of the specifications and the drawings before inspecting joint construction. All transverse joints are to be constructed normal to the centerline of the pavement lane unless otherwise noted on the construction plans.

Joint sawing is required to prevent uncontrolled cracking of concrete pavement and is required for all transverse contraction joints and for all longitudinal joints when concrete pavement has been placed between two lanes at the same time.

Joint openings are to be constructed in accordance with the requirements of the applicable standard construction drawings.

The timing of the sawing operation is critical. The use of HIPERPAV software is required to determine the sawing time limits to help protect from early uncontrolled cracking. The software is available as detailed in Supplement 1033 as well as the requirements for analysis. It must be noted that the use of HIPERPAV does not relieve the Contractor of his responsibilities under 451.16 regarding the repair of cracks in the completed pavement.

The HIPERPAV analyses must be run 24-hours prior to placing concrete and for every pour. The HIPERPAV files and printout must be provided to the Engineer. If HIPERPAV predicts early age slab cracking will occur, whether due to standard construction practices, joint sawing methods, mix design or curing, the contractor cannot start construction until modifications have been made to eliminate HIPERPAV’s predicted slab cracking.

If HIPERPAV predicts that joint sawing can exceed 24 hours, all joints must be cut by the 24th hour.

Sawing must be done after the concrete hardens sufficiently to support the sawing equipment and to avoid spalling and raveling. This operation cannot be tied to normal working shifts. A standby saw is required at the paving site in the event of breakdown or inability of one machine to maintain necessary progress.

Inspection should include random checking of each day’s sawing to assure the width and depth specified is achieved. Saw blades will wear with use so continued checks must be made. Since the timing of sawing is critical, inspectors assigned to this operation must be aware of the importance and document the actual time of sawing.

Sawing may be done wet or dry, and the cut must be cleaned by a jet of water (if sawed wet) or air under pressure (if sawed dry).

Longitudinal Joints

(451.08.A)

Joints between adjoining lanes of pavement or shoulders are longitudinal joints. They are necessary to control cracking in the longitudinal direction due to the warping stresses in wide concrete slabs. Joints between separately-placed adjoining lanes are longitudinal joints as well as construction joints. In general, the maximum pavement width used by the Department without a longitudinal joint is 16 feet (4.9 m) (for ramp pavements). Normal mainline pavements are 12 feet.

Epoxy coated tiebars or hook bolts are required at longitudinal joints to tie the lanes and prevent them from moving apart or from settling unevenly. Since they tie the lanes together by bond, tiebars or hook bolts are not to be oiled.

Longitudinal Joint

- (in simultaneously placed lanes)

Both tiebars and hook bolts should be placed in accordance with requirements of standard construction drawings called out in the plans. Tiebars are 5/8-inch (16 mm) diameter, deformed reinforcing bars, 30 inches (760 mm) in length. The spacing of tiebars or hook bolts varies with the pavement thickness. The maximum spacing of tiebars is 26 inches for pavement that is 10 inches (250 mm) thick or less, and 20 inches (508 mm) for pavement that is greater than 10 inches (250 mm) in thickness. Tiebars or hook bolts must be approximately at right angles to, and placed at 1/2 the thickness of the pavement. For example if the slab is 10 inches thick the tiebars are to be placed at 5 inches as measured from the surface of the slab.

Tiebars may be set on chairs prior to concrete placement; installed in the concrete after it is placed and spread; or may be inserted in the plastic concrete using a mechanical device on a slip form paver. Chaired tiebars must be adequately anchored to the base material. A mechanical inserter must be able to install the tiebars at mid-depth in the plastic concrete. Tiebars must be inserted after the concrete has been placed to its full depth and after the reinforcing mesh is placed (mesh is not required for 452 pavement). The tiebar inserter must be located in the paving train to assure consolidation of the concrete around the tiebars. Pushing tiebars into the plastic concrete by hand is not acceptable.

Mechanical Devices for Installing Tiebars in Longitudinal Joints between Lanes Placed Simultaneously – Wheel

Mechanical Devices for Installing Tiebars in Longitudinal Joints between Lanes Placed Simultaneously –Guillotine

Tiebars Can be Chaired at Longitudinal Joints Prior to Concrete Placement

When a standard (water-cooled diamond bladed) concrete saw is used to make the longitudinal joint between simultaneously placed lanes the following applies:

· Pavement ≤ 10 inches thick; saw the joint to a minimum depth of one-fourth the specified pavement thickness.

· Pavements > 10 inches (255 mm) thick; saw the joint to a minimum depth of one-third the specified pavement thickness.

· Saw joints 1/4 ± 1/16 inch (6 ± 1.6 mm) wide as measured at the time of sawing.

When using early-entry (dry cut, light weight) saws, only use saw blades and skid plates as recommended by the manufacturer. Perform the early entry sawing after initial set and before final set as follows:

· Saw the joint 2-1/4 to 2-1/2 inches (56 to 63 mm) deep.

· Saw joints approximately 1/8 inch (3 mm) wide as measured at the time of sawing.

Longitudinal Joint

- (between separately placed lanes)

Standard 30-inch long tiebars can be installed in the slip formed edge of the pavement using a mechanical inserter at longitudinal joints when lanes are placed separately. This is normally done by a mechanical ram which pushes a tiebar 15 inches into the edge of the slab along the joint and at the center of the slab. Tiebars cannot be placed by hand. Bent tiebars are not permitted in longitudinal construction joints.

Mechanical Ram Inserts Tiebar in a Slip Formed Edge

Hook Bolts Screwed into Coupling at a Butt Joint

The epoxy coated hook bolt or an epoxy coated hook bolt alternate (wiggle bolt) may be used in longitudinal joints when using fixed form paving. An epoxy coated coupling attached to one half of the device is bolted to the side-form for the first lane placed. Before placing concrete in the adjoining lane, the other half is coupled to the embedded part after removal of the forms. The hook bolts are to be securely fastened to the forms so they are positioned properly in the slab. The right-angled hooks on each side of the coupling anchor provide the tie. The position of the hooks is not important, that is, they do not have to be turned down, up, or sideways.

The hook bolt alternate (wiggle bolt) with a coupling may be mechanically inserted into the plastic concrete through a hole in the side-form of a slip form paving machine. When this is done, the contractor normally uses a plastic cap in the threaded end of the coupling to keep concrete out of the threads. This plastic cap is removed once the concrete is set and a hook bolt is installed in the coupling.

The inside and outside edges of the paved lane must be edged to a 1/8-inch (3 mm) radius. The slab should be edged as soon as the concrete becomes stiff enough to remain firm without running back into the groove. The edge should be cut first with a small trowel and then followed by the edger. The edging tool should be held flat with the pavement surface. Tool marks left by the edging tool must be removed. Since the final texturing is to follow edging, this operation must not be permitted to lag.

Tooling with a 1/8 inch Radius Edger

Tool Marks are Removed after Edging

Longitudinal joints between separately placed lanes are to be saw cut to a minimum depth of 1/2 inch (13 mm) and a minimum width of approximately 1/8 to 1/4 inch (6 mm).

Longitudinal joints between separately placed lanes require extra care to assure that a smooth transition from one lane to the other will result. Good workmanship is necessary at these joints to obtain satisfactory results. Hand finishing and straightedging should be performed carefully so that each lane will be at the same elevation. The surface of the pavement in the joint area should not vary more that 1/8 inch (3 mm) from a 10-foot (3.0 meter) straightedge in both longitudinal and transverse directions.

Tooling a Longitudinal Joint at a Butt Joint

Tooling the Edge when Fixed Form Paving Contraction Joints (451.08.D)

Load Transfer

Devices (451.08.B)

Contraction joints in concrete pavement are constructed at right angles across a pavement lane and are also called transverse joints. These joints control cracking of concrete pavement that result from stresses from volume changes during curing of the concrete. These joints are designed to transfer the loading from traffic from one slab to the next and require the use of dowel bars to accomplish this function. These dowel bars are called load transfer devices. Dowel bars can be pre-installed using dowel bar assemblies or can be installed using dowel bar inserters during slip form paving.

In contraction joints load transfer is achieved using round, straight, smooth, epoxy-coated steel dowels that are placed across the joint. Dowels must be placed at mid-depth, parallel to the slab and be 18 inches long. The required diameter of the dowel depends on the pavement thickness. The required dowel diameter is shown in Table 451.08-1 in the specifications and below (unless otherwise specified in the plan):

Table 451.08-1 Dowel Size

|

Thickness of Pavement (T) |

Diameter of Steel Dowels |

|

Less than 8 1/2 inches (215 mm) |

1 inch (25 mm) |

|

8 1/2 to 10 inches (215 to 255 mm) |

1 1/4 inches (32 mm) |

|

Over 10 inches (255 mm) |

1 1/2 inches (38 mm) or as in the plans |

Dowels must be spaced at 12-inch (300 mm) centers beginning 6 inches (150 mm) from the longitudinal joint. The spacing between the end dowel and the outside edge of the lane may be increased up to 12 inches (300 mm). A dowel must be placed 6 inches (150 mm) from the outer edge of the pavement when the spacing between the end dowel of the basket and the outside edge exceeds 12 inches (300 mm). Contraction joints are required to be spaced in the pavement at intervals not to exceed the maximum spacing indicated in Standard Construction Drawing BP-2.2 or the plan construction drawings. The maximum contraction joint spacing for reinforced concrete pavement (Item 451) is 21 feet (6.5 m). For non-reinforced concrete pavement (Item 452) and concrete base (Item 305) the maximum spacing is 15 feet (4.6 m).

To function properly dowels must be placed parallel to the surface and parallel to the centerline of the pavement since expansion and contraction movements occur in this direction.

Dowel Basket

Assemblies

To assure proper alignment of dowels, a cage or basket is often used. This, together with the dowels, is called a dowel basket assembly. Dowel basket assembly wires as well as the dowels are required to be epoxy coated according to 709.13 of the CMS. Dowel basket assembly wires are to conform to Standard Construction Drawing BP-2.2.

Dowel basket assemblies are to be positioned not to exceed the maximum spacing for the type of pavement specified and must be perpendicular to the centerline and edge of proposed pavement or forms. Locating the transverse alignment may be by any method that assures a right angle to the centerline. On curves, the joints should be approximately on radial lines.

Transverse contraction joints must be continuous across the full width of pavement placed. Therefore, the line of a joint in a lane already placed must be continued in all other adjoining lanes.

Dowel Baskets are Pinned to the Base