204 Subgrade Compaction and Proof Rolling

Importance

Over 25 million dollars of

extra work was used to stabilize unstable subgrades during the construction

seasons of 2000 and 2001. This extra work

has been minimized in recent years because of the construction and design

criteria created since that time.

This section will help the

project construct stable subgrades for pavement construction. Proper subgrade treatment ensures a

constructible pavement, enhances pavement performance over its life, and

ensures that the pavement design intent is carried through into the

construction phase. This section is

based on research performed by the Department from the 1960’s through

today. This section should not be used

as the ultimate answer to solve all subgrade problems.

This section is detailed in

such a manner so that construction personnel can easily apply information from

the field and subsurface investigation to provide reasonable adjustments to the

plan subgrade treatment.

Specification

and Plan Requirements

Item 204

requires the top 12 inches of the subgrade to be compacted. Item 204

requires the subgrade to be proof rolled.

If subgrade stabilization or undercutting is designed for the entire

project, then proof rolling is only used to verify the stability of the

stabilized subgrade. If special subgrade

treatment is provided in the plans at spot locations, proof rolling is

specified to identify these areas and then performed afterwards to verify the

undercut stability.

Proof rolling deflections and

soil conditions that are observed during construction determine if the plan

subgrade treatment must be adjusted.

Adjustment of subgrade treatment to fit field conditions is essential and

is the responsibility of the Project Engineer.

Subgrade Correction Prior to Proof Rolling

The Engineer must observe the

effect of heavy equipment, which operates on the subgrade during rough

grading. When rutting and deflection

under heavy equipment indicates unstable subgrade, the Engineer should

authorize the correction. See Elasticity

and Deformation of Soils in Section 203.02 of this manual.

Do not delay the correction

until it can be checked by proof rolling.

Investigate the extent of the problem by using the Investigation section

of this Item. Be aware that the

condition can be improved by time, drainage, and hauling as detailed in the

section, Draining and Hauling, of this item.

If needed, make the

correction by excavating and disposing of unstable soil and replacing it with

suitable material as detailed in the section, Undercut Depth and Stabilization

Determination, of this item.

Drainage and

Hauling

Excess water in fine-grained

soil is the principal cause of unstable soil conditions. The Engineer has a responsibility to ensure adequate

drainage during construction. If the

investigation indicates the need for underdrains or the cleaning of the

existing underdrain outlets, the Engineer must order the work as soon as

possible.

Some examples of these

conditions are as follows:

1. Existing underdrains with clogged outlets on

rehabilitation projects.

2. Free water in the subgrade.

3. Saturated soils of moderately high permeability, such

as sandy silt and silty clay of low plasticity.

4. Ground water seepage through layers of permeable soil.

5. Water seeping into test pits.

6. Water seeping from higher elevations into cut

locations.

7. Water flowing on the top of the rock or shale in

subgrade undercuts.

Note: It is difficult to

remove water from hard clay soils with PI’s greater than 20 with construction

underdrains.

Subgrade stability can be

significantly improved by cleaning out the existing underdrain outlets on

rehabilitation projects and by adding construction underdrains on new or

rehabilitation projects. Once the

underdrain systems are in place and functioning, the drainage system can reduce

the subgrade soil moisture content from 3 percent over optimum moisture to the

optimum moisture content in 6 to 8 weeks.

Moisture contents that exceed 3 percent over optimum must be dealt with

by other means.

For rehabilitation projects,

the Contractor should be instructed to unclog the underdrain outlets

immediately. Try to perform this work in

the time frame listed above. If the project

consists of several phases, instruct the Contractor to perform the outlet

cleaning for the entire project at the same time.

For new or rehabilitation

projects, subgrade stability can be achieved by constructing the plan or

construction underdrains as soon as the water problem is found. On new construction projects, a longer period

of time can be allowed for the underdrain system to work. Opportune times for this work are at the

beginning of construction and before winter shut down.

The plan underdrains should

be placed only when they will not be contaminated by further construction. If contamination is a concern, then

sacrificial or construction underdrains should be used on the project.

Item 605

in the C&MS details the construction of construction underdrains.

Construction underdrains are usually placed in the centerline of the roadway,

but can be placed in other locations too.

They may be placed in the ditch line if water is coming in from a cut

section at a higher elevation. The

porous backfill is extended to the subgrade elevation. The outlets for the construction underdrain

are the same pipe material and backfill as regular underdrains. The underdrains can be outlet to any

convenient location, such as catch basins, manholes, pipe, or ditches. The project should not be concerned with

contamination in the upper portion of the underdrain backfill. Construction underdrains are sacrificial

underdrains that will continue to work throughout the life of the contract and

afterwards, even though the upper portion is contaminated.

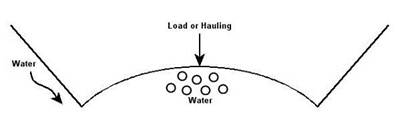

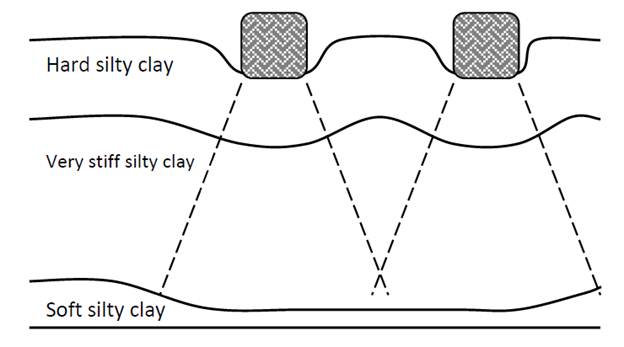

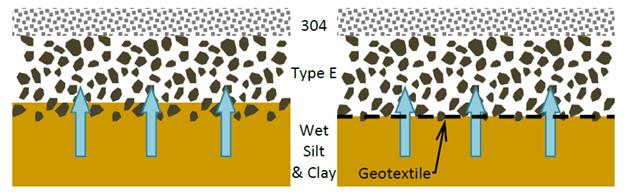

In Figure 204.A, the subgrade

is saturated and the soil acts like a waterbed when the subgrade is Proof

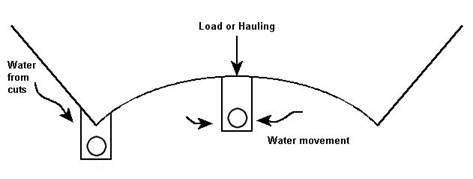

Rolled or hauled on. However, once the

underdrains are in place and the soil is loaded, as shown in Figure 204.B, then

the water has a place to go. As the soil

is loaded or hauled on, the water is squeezed out and the subgrade conditions

will improve.

Figure

204.A – Water in the Subgrade without Drainage

Figure

204.B – Water in the Subgrade with Drainage

By placing the drainage

system prior to loading or hauling on the subgrade, the water is given a

location to escape the subgrade system.

If the drainage system is not in place before hauling or loading, the

subgrade will rut or crack and have a detrimental effect on the subgrade and

not improve with loading.

Drainage and hauling can work

together to correct unstable subgrades under the above given guidelines.

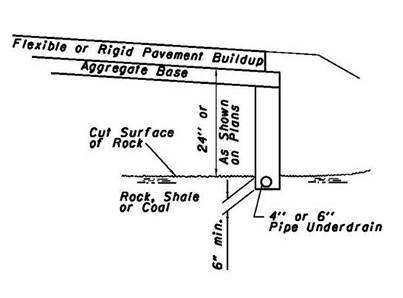

Figure 204.C, Shale and Rock

Undercuts, came from Figure 1009-10 in Location

& Design Manual – Volume 2, Drainage

Design. The specification

requirements are detailed in 204.05. Shale and rock are cut 24 inches (610 mm)

below the bottom of the pavement. This

ensures that the pavement gets uniform support and good drainage. When rock is blasted and excavated, the

resulting surface is very rough and tends to collect water. Accumulated water will cause some rock and

shale to deteriorate. By undercutting the rock, we ensure that any water that

collects in the irregular surface does not affect the pavement. In the past, pavement placed on rock and

shale started to develop problems immediately after opening to traffic.

Figure

204.C – Shale and Rock Undercuts

The underdrains in these rock

and shale cuts should extend at least 6 inches (150 mm) into the existing rock

or shale formation. If the underdrains

are too high, the water will accumulate at the rock and soil interface and

cause subgrade instability.

Construction or rock

underdrains can be placed in the ditches and other strategic locations in cut sections

to minimize water coming under the pavement.

Water under the pavement without drainage causes the subgrade to act

like a waterbed. With drainage, the

conditions improve and become more stable.

When to Proof Roll

For areas where subgrade

appears to be stable without undercutting, proof roll after the top 12 inches

(305 mm) of the subgrade meets the compaction requirements and after the

subgrade has been brought to approximate shape within 0.1 to 0.2 feet (30 to 60

mm) required by plan lines.

For areas that are obviously

unstable and require undercutting, do not proof roll unnecessarily to

demonstrate that subgrade correction is required.

The proof rolling should be

done immediately after the subgrade compaction operation, when the moisture

content of the subgrade soil is near the moisture content that was used to

achieve compaction. This minimizes the

subgrade becoming too wet or too dry for an effective proof rolling evaluation. If the subgrade is too wet, the material will

displace and rut. If the subgrade is too

dry, a hard surface crust may carry the proof roller over an undesirable, soft,

wet, underlying material without rutting or deflection, and the unstable

subgrade may not be detected.

Proof rolling may be done

either before or after pipe underdrains are installed. If done after underdrains are installed,

rolling should not be done directly over the underdrains. In C&MS 204.06, proof rolling must be

performed at least 1.5 feet (0.5 m) away from the underdrains because of the

potential damage to the underdrains.

Proof

Rolling

(204.06)

CA-EW-2

Proof Rolling Documentation Form is used to document the proof rolling

operation. It is imperative that the

stations, deflections, weight of the proof roller, and comments are well

documented. Digital photographs of

subgrade distress are highly recommended.

The primary purposes of proof

rolling are to locate unstable areas, check the subgrade compaction, to carry

out the intent of the design, and to provide uniform support for the pavement

structure. Unstable subgrade areas that

are located will be corrected so that the subgrade density can be maintained throughout

the construction. If done correctly, the

pavement design intent will be carried through the construction process.

One trip with a proof roller

is adequate to achieve satisfactory proof rolling results.

An over loaded proof roller

for a soil type may cause satisfactory subgrade to become unstable during proof

rolling. Conversely, unstable areas will

not be found if the proof roller is too light for the soil type.

Selection of Proof Roller Weights

and Tire Pressure

In view of the many variations

which must be expected in Ohio soil and moisture conditions, the Engineer is

given authority to vary the weight and tire pressure of the proof roller to fit

the conditions. The weights and tire

pressures for the different soils are detailed in C&MS 204.06.

It is imperative that the

project chooses the correct load for the type of soil on the project. These loads and tire pressures are soil type

sensitive when evaluating the subgrade.

For A-3, A-4, A-6, and A-7 soils use a 35 ton (32 metric ton) roller

with a tire pressure of 120 psi (820 kPa).

This load and tire pressure is used on most projects because these are

the most common soils found in the State of Ohio.

For granular soils and soil,

rock, and granular mixtures, use a 50 ton (46 metric ton) roller with 120 psi

(820 kPa) tire pressure. However, if the

granular material was placed as part of an undercut to stabilize an unstable

subgrade, then use the weight appropriate for the original subgrade materials

(35 tons).

The goal of proof rolling is

to maximize the load to locate unstable subgrade. These unstable soils could be 3 to 5 feet (1

to 2 m) deep. In rare cases, the

unstable soil may be deeper than 5 feet (2 m).

Close inspection throughout

proof rolling is necessary to observe the rolling effects and to mark unstable

subgrade locations for correction or investigation. Inadequate stability is indicated by deflection,

cracking, or rutting of the surface of the subgrade.

Failure Criteria

When is rutting from the

proof roller an indication of unstable subgrade? Technically, the maximum

allowable rutting or elastic movement of the subgrade is the amount that allows

the subgrade soil to maintain the specified density throughout the construction

process. For example, if subgrade

density can be maintained with 6-inch ruts, then this would be the allowable

maximum. In practice, when the ruts from the proof roller are deeper than 1

inch, then there is usually cause for concern.

Additionally, if the subgrade deflects more than 1 inch with substantial

cracking or lateral movement of the soil, then this is also cause for concern. Elastic deflection is when the subgrade moves

down under the weight of the proof roller and then comes backup (rebounds)

after the proof roller passes.

When rutting and deflections

are less than 1 inch, there is no assurance that overlying pavement

construction will not damage the subgrade compaction. Although subgrade density and stability can

be maintained during proof rolling, the repetitive loading, the hauling of

materials, and the base and pavement construction can still destroy the

subgrade compaction. This may be an

issue on some reconstruction projects.

On reconstruction projects, the following complications can create or

worsen subgrade problems.

1. Water accumulates under the pavement because of poor

drainage or clogged underdrain outlets.

2. Construction time frames are limited.

3. Space limits the ability to dry the material in

place.

4. Once the pavement is removed, all the drainage is

toward the subgrade. This compounds an

already poor drainage situation.

5. Alternate haul routes are limited or not available on

rehabilitation projects.

The failure criteria are used

in this section to determine the locations from which to perform a detailed

analysis. This detailed analysis

consists of methods discussed later in this section, such as rut depth, soil borings,

and test pits. If the subgrade deflects

beyond the failure limits given in this section, and the soil borings and test

pits determine that the subgrade does not need to be undercut, then the

subgrade should be considered satisfactory.

One additional area to evaluate is the moisture content of the

soil. Some soils are more prone to rut

at moisture contents greater than 3 percent below the optimum moisture

content. In fill locations, the moisture

content can be reduced to minimize this problem. If all of the above criteria are met, there

is no reason the subgrade should not perform as anticipated. If there is any debate between the Department

and the Contractor, especially if a warranty is involved, then further

nondestructive or destructive testing can be used to resolve the issue.

In Figure 204.D, the soil has

been compacted in the top foot of the subgrade and the conditions are good for

the top 3 feet (1.0 m). However, there

is a soft layer at a lower elevation.

The soft layer has no detrimental effect on the subgrade density during

the subgrade compaction.

Figure

204.D – Stage 1 Compaction of Subgrade

In Figure 204.E the proof

roller deflects because of the soft soils. The subgrade density may or may not

be affected by the proof rolling. The

loss of subgrade density is proportional to the amount of rutting or elasticity

during proof rolling and subsequent construction operations. The severity of the overall subgrade

condition can be measured by the amount of the deflection and elasticity on the

surface.

Figure

204.E – Stage 2 Proof Rolling

When the proof rolling

deflections exceed the failure criteria; the proof rolling, repetitive loading,

and pavement construction can destroy the top layers of the aggregate base and

subgrade.

In actual field conditions,

this soft layer can be just a few inches thick and at any elevation from the

top 1 foot (0.3 m) to as deep as 5 feet (2 m).

In addition, it may be an indication of an overall soil condition that

is just over optimum for the entire 5 foot (2 m) depth of the subgrade. The test pit excavation is used to identify

the layer, or layers, causing the surface distress. This is further detailed in

the section, Investigation, of this Item.

It is imperative that these conditions are correctly identified.

Crusting is a condition when

the subgrade surface appears to be dry and there is substantial cracking on the

surface with or without rutting. This

indicates a need for further investigation and usually indicates soft or wet

underlying soil at depth with the top foot or so of the subgrade being very

dry.

Variations in the Proof Rolling

Results

You should not be too

concerned with occasional or nominal deflections in excess of the above failure

criteria. If the density is checked, and

the investigation shows that good soil extends throughout the top 5 feet of the

subgrade, then the design intent will be fulfilled and the project can be

constructed. All soils will occasionally

deflect under these loads.

The pavement design is based

on an average CBR. The CBR value was

directly correlated to soil density many years ago. By using the average CBR (Density) value, the

pavement design accounts for a 30 percent, or one standard deviation variation,

in the subgrade strength from the design CBR. Fifteen percent is expected to

exceed this value and 15 percent is expected to be less than this value. Some variation in the subgrade condition is

already accounted for in the pavement design.

Another consideration is the

fact that these proof rolling loads and tire pressures are about 10 times the

final in-place stresses once the pavement is constructed. The proof rolling tire pressures are between

120 to 150 psi (820 to 1030 kPa) and the stresses, once the pavement is

constructed, are about 8 psi (55 kPa) for a thin asphalt pavement and 4 psi (27

kPa) for a thick concrete pavement.

These loads are the largest loads that the subgrade will encounter.

If the project can be

constructed while maintaining subgrade density, the subgrade design intent will

be fulfilled.

The project should not be

concerned with the “Pavement Warranty” issues that Contractors often bring

up. If the project follows these guidelines,

and properly documents the subgrade work, Central Office can defend the

warranty issue.

Once failure is established

based on the proof rolling results, the responsibility for the correction of

the failure should be determined.

Responsibility for the Unstable

Subgrade

If unstable subgrade

locations are found, take compaction tests to determine if the specifications

are met in the top 12 inches (300 mm).

The Engineer should instruct the Contractor to correct any deficiencies

found in these locations.

The

Department is responsible when the unstable subgrade is encountered in:

1.

Cuts.

2.

On reconstruction

projects.

3.

In shallow fill

locations where the unstable material is found under the contract fill.

4. When the unstable material is found at lower elevations

than the project contract work.

Subgrade stability may not be

possible by compacting the upper 12 inches (0.3 m) because of conditions at

these lower elevations.

It is the Contractor’s

responsibility to correct all unstable locations in fills. If the Contractor built the fill correctly,

the proof rolling will do nothing but verify specification work. If the fill fails then the proof rolling will

determine the location of the deficient specification work.

If the Contractor fails to

maintain the subgrade, the Engineer should instruct the Contractor to repair

the failed areas. See C&MS

203.04.A for the Contractor’s responsibility to drain and maintain the

subgrade.

Investigation

Investigate the causes of

failed locations quickly to expedite the corrective treatment. Three pieces of information are needed to

make the most economical subgrade treatment:

1. Rut depth.

2. Soil boring information.

3. Test pit data.

At this point, the rut depth

has already been determined.

Soil Boring Information

For rehabilitation projects

or cut sections, the soil borings can be examined to determine an estimated

undercut depth or stabilization methods.

Evaluate Standard Penetration

Test (SPT) results from soil borings in the failed subgrade locations. The Standard Penetration Test (SPT) is an

indicator of soil consistency or strength and measures the number of blows per

foot (N) required to drive the soil sampler through the soil. The soil data on the boring logs are

presented as the number of blows required to drive each 6-inch (150 mm) increment. The first 6 inches (150 mm) of the run is

ignored because the sampler may not be seated in the borehole or may be driven

through cuttings. For example, standard

penetration data shown as 1/2/3 has an N value of five blows per foot.

When investigating the need

for undercutting or stabilization in failed locations, look at the borings in

those locations in the upper 5 feet (1.5 m) of the subgrade. At each location, pick the lowest N value

when multiple N values are taken in the top 5 feet (1.5 m) of subgrade.

Average the N value along the

failed locations. This value provides

one part of the information needed to determine the undercut depth or

stabilization methods.

Test Pits

Once the soil borings have been

evaluated, construct test pits by excavating 3 to 5 feet (0.6 to 1.5 meter)

into the subgrade using the Contractor’s excavation equipment. Excavate at least two test pits that

represent the failed area. Use judgment

for long areas, usually about two to four test pits per mile is

sufficient. Construct the test pits

across the width of the subgrade in the failed locations. Pick locations with the highest deflections

to evaluate the most severe locations.

Warning: These trenches may

collapse on the construction personnel.

The Department offers an 8-Hour Construction Safety Class to evaluate

the trench collapse risk. In addition,

there is a trench safety class offered by the Bureau of

Workers Compensation, Division of Safety and Hygiene. These classes are given statewide, all year

around. (614-466-5563)

An examination of the soil

and moisture conditions in these test pits provides valuable information to

make the appropriate correction. Once

the pits are excavated, the Engineer must examine the trench sidewalls and the

bottom of the cut.

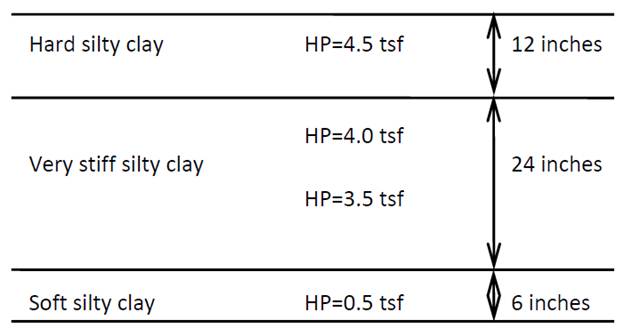

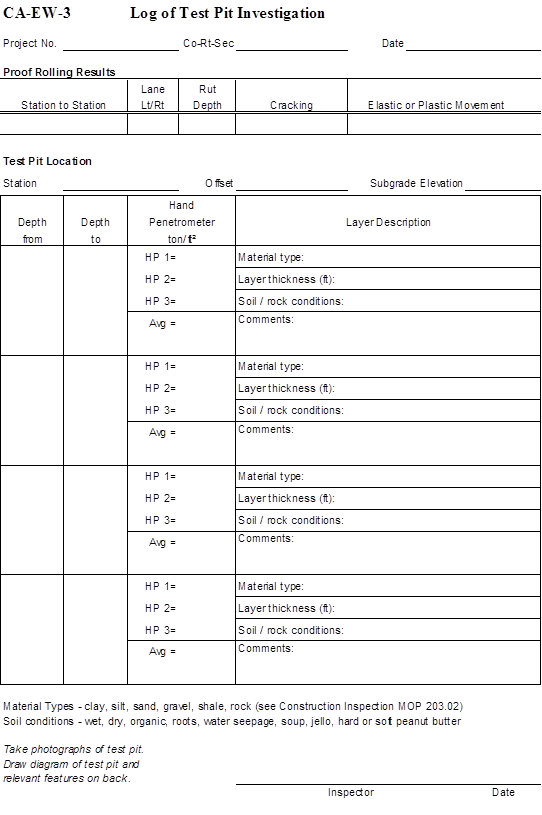

Record the test pit

information on CA-EW-3

Subgrade Test Pit Investigation form shown in Figure 204.G. The soil conditions vary with depth and must

be quantified. By examining the

sidewalls, the Engineer can determine the soil type, layer thickness, soil

condition, and soil strength by using a hand penetrometer.

Figure

204.F – Form CA-EW-3 Subgrade Test Pit Investigation

The Engineer must field

classify the soil. See 203.02 Materials,

Identifying Soil and Granular Materials in the Field, for help in the

classification.

Added soil conditions are

described on the bottom of the test pit form.

These conditions are stated in commonly-known consistencies, so that the

non-geotechnical reader can relate to the soil conditions. They are listed on the bottom of the

form. No explanation is needed for these

terms.

Hand Penetrometer Readings

A hand penetrometer can be

used to further classify the soil and to estimate its strength. A hand penetrometer can be obtained from a

test lab supply company for less than $100.

Hand penetrometers can be obtained from the following companies:

|

Gilson |

Model # HM-500 |

|

ELE |

Model # E129-3729 |

|

Humboldt |

Model H-4200 |

The exact instructions come with

the hand penetrometer. In summary:

1. Push the hand penetrometer slowly into the soil

perpendicular to the surface.

2. Record the reading when the hand penetrometer

penetrates the soil to the 1/4-inch groove mark.

3. Record the readings to the nearest 0.25 tons per

square foot (tsf).

4. Take at least three different readings in each soil

layer.

Use the CA-EW-3

Subgrade Test Pit Investigation form to record the readings. Average the readings once three readings are

taken for the soil layer. Also, evaluate

the bottom of the test pit; this is extremely valuable information. Average the hand penetrometer readings (HP)

of all the test pits in the failed locations.

Use this number to further evaluate the undercut depth or stabilization

methods.

Consider the following when

evaluating the sidewalls of a trench:

1. Different layers of a natural formation or cut are

more noticeable than fill materials.

2. High hand penetrometer readings may be obtained with

high deflections or rolling at the surface. This is an indication of soft soil

at a lower elevation than 5 feet (2 m) or a subgrade soil that is just too wet.

Undercut Depth and Stabilization

Determination

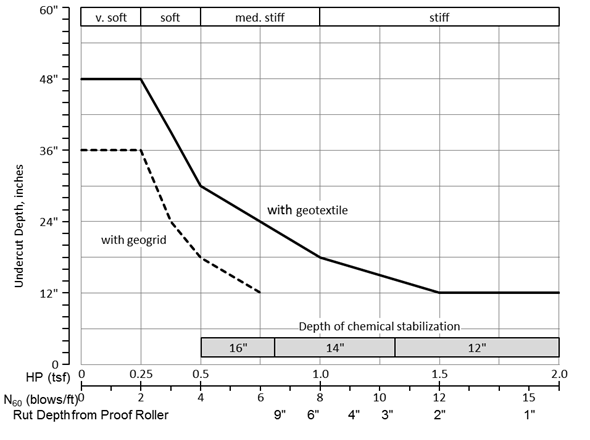

Once the proof rolling rut

depth (in inches), soil boring information (N), and hand penetrometer readings

from the test pits (HP) are obtained, use the Subgrade Treatment Chart in

Figure 204.H to determine the recommended depth of undercut or chemical stabilization. The input values (rut depth, N and HP) are on

the horizontal axis. The two curves show

the undercut depth with a geotextile and with a geogrid. The chart also shows the

stabilization depth required in inches along the bottom. Note that the results from this chart are

guidelines. The subgrade conditions might require undercuts that are less than

or greater than those shown, because subgrade conditions can be highly

variable.

Figure

204.G – Subgrade Treatment Chart

The subgrade treatment chart

takes into account some variation in test results, the anticipated loading from

the proof roller, and typical truck loading during construction.

Use the rut depth, N values,

and hand penetrometer readings (HP) to draw a vertical line to the curve. The recommended depth of the undercut is

where the vertical line intersects the curve.

For soft and very soft soils, it may be economical to use a geogrid to

reduce the depth of the undercut. The

geogrid restrains the granular material from lateral movement and makes it more

effective. Refer to Supplemental

Specification 861 for using geogrids for subgrade stabilization.

The chart does not recommend

chemical stabilization for soft and very soft soil. This is primarily because of constructability

problems. Although chemical

stabilization does improve the stability of soft and very soft soils, these

soils usually cannot support the equipment used to perform the chemical

stabilization.

It would be rare to see a

perfect alignment in the results from all three inputs. In some cases, one or two of these inputs may

not be available. In other cases, some

judgment is needed to redesign the most economical undercut that will

work. In order of hierarchy, use the

test pit data, then the N values, and then the rut depth. The rut depth is the least reliable indicator

of undercut need because it cannot determine which soil layer is causing the

deflection.

There will be cases where the

N values and unconfined values are all high, but the subgrade is rolling and

cracking, and rut depth is greater than allowable. In this case, use the rut depth as a guide to

redesign the undercut. See the last

example in the example section.

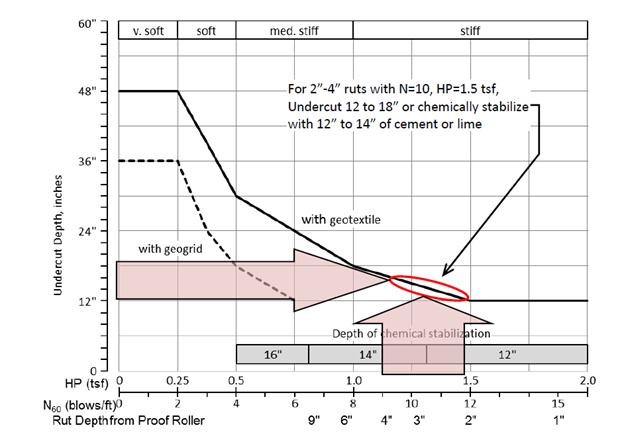

There is an example in Figure

204.I.

Given: Average N

value was 10.

Average HP= 1.5 tsf.

Average Rut Depth was 2 to 4 inches.

Answer: Use

an undercut depth of 12 to 18 inches with a geotextile or chemically stabilize

with 12 to 14 inches of cement or lime.

For very large areas, give serious consideration to the stabilization

method. It will be more cost effective.

Figure

204.H – Example using the Subgrade Treatment Chart

After making the undercut,

this depth may need to be adjusted to meet the actual conditions. See the section, “Implementation during

Construction,” of this manual.

General Rules

On new construction projects,

if all of the unstable material can be removed, and the bottom of the test pits

or cuts are stable, then soil may be used as replacement material. For reconstruction projects, soil is usually

not available in large quantities.

Therefore, soil undercuts are less effective solutions on reconstruction

projects.

If the bottom of the test pit

is unstable when conditions are highly variable or for rehabilitation projects,

use granular material, rock, geotextile, geogrid, or chemical stabilization

rather than soil.

Undercuts should be used in

small locations or in areas where spot locations are identified. Consider chemical stabilization for long

areas greater than one mile.

Only the most unusual cases

require removal to depths greater than 3 feet (1 meter). Seventy five to 90 percent of subgrade

problems can be solved with a 1 foot treatment of granular material and

geotextile or chemical stabilization.

If a project or section of a

project undercut locations are more than 30 percent of the total area, undercut

or chemically stabilize the entire area.

If you do not undercut the entire area, these locations will grow, and

the construction will be inefficient as the construction proceeds. The

Department pays a higher cost at a reduced, final quality by undercutting a

high percentage of the subgrade throughout the project. ODOT would not repair a bridge deck or

pavement with this high a percentage of repairs.

Chemical stabilization

methods speed construction because of the ability to work immediately after a

rain. Estimates indicate that the

construction production is increased by at least 50 percent by using

stabilization methods.

Examples:

The following table shows

some example solutions. The types of

material refer to 703.16.C and Item 206.

|

Given |

Solution |

|

Project with Silty A-4a material with N=15 or HP=2.0 tsf Rut Depth>1" |

12 inches of Granular Material Type B, C or D with

geotextile or 12 inches of stabilization with cement |

|

Project with Deep, weak, and wet A-4a with N = 12 or HP=1.4

tsf Rut Depth = 2" |

18 inches of Granular Material Type B, C, or D, with geotextile

or 12-14 inches of stabilization with

cement |

|

New Construction,

Deep, weak & wet A-4a, A-6 or A-7-6 combination with N = 10 or

HP=1.0tsf. Rut Depth = 4" |

18 inches of Granular Material Type B C or D with geotextile or 14 inches of

stabilization with lime or cement. (Check the PI of the soils. Use the

stabilization type according to the PI’s of the soil.)

|

|

New Construction Jell-O like consistency soil with N = 5 or

HP=0.5 tsf. Rut depth > 6" |

30 inches of Granular Material Type B, C, or D, with

geotextile, or 18 inches of granular material with geogrid and

geotextile, or 16 inches of chemical

stabilization. ( Check the PI of the soil.) |

|

Any Project with

soup like consistency soil with N =

2 or HP=0.25 tsf Rut Depth = Buried equipment |

4 feet of Granular

Material Type B, C, or D, with geotextile, or 3 feet of granular material

with geogrid and geotextile. (Use type

D Granular Material if available) |

|

Reconstruction Project Sandy, A-4a, A-6a soil, PI < 20,

N = 8 or HP=1.0 tsf Rut Depth = 6". (Long Project) |

Cement Stabilized Subgrade 14" deep at 6% |

|

New construction A-7-6 clay soil, PI > 20 N = 11 or HP=1.2 tsf Rut Depth =3".

(Long Project) |

Lime Stabilized Subgrade 12" deep at 5% |

|

Reconstruction Project A-6a silty clay PI < 20, N=30 and HP>4.5 tsf Rut depth > 2" and rolling The key here is the rolling. Probably caused by high

moisture content of the soil at a depth.

If the subgrade is rolling with one pass of a proof roller then the

subgrade condition can rapidly deteriorate during construction. |

16" of Cement at 6% or 2.5 foot undercut

with Granular Material Type B, C, or D, with geogrid and geotextile. Use Type D material if available. |

Type of Undercut Materials

Use Granular Material Types

B, C, D, E, and F. They are generally

cheaper than 304.

Type B is a well-graded

aggregate with the gradations of Items 304, 411, or 617. Type C has a top size of 3 inches and type D

has a top size of 8 inches. Both C and D

are well-graded materials. The larger

top size material will bridge the unstable material better than the smaller

size material.

Use Granular Material Type E

when water levels are high or cannot be drained. The Type E materials are very porous. Always choke the Granular Material Type E

with Granular Material Type B or geotextile fabric.

There is a potential for

piping of soil into the Granular Material Type E as shown in Figure 204.J. In the figure on the left, when the open

graded material is placed on wet, fine-grained soil, the soil pipes into the

open graded material during construction.

In the figure on the right, the geotextile fabric blocks the

fine-grained soil from entering the open graded material. Geogrids will not perform this separation

function.

Figure

204.I – Soil Piping in Open Material

Underdrains cannot be placed

through Granular Material Types D, E, or F.

Use Granular Material Type B in the locations of underdrains. Underdrains can be trenched through

geotextile and geogrid if there is enough material above the geotextile or

geogrid to confine it. Always drain the

undercut to an underdrain, catch basin, or pipe.

The use of 712.09

Geotextile Fabric Type D is recommended in most cases. The cost is around $1.00 per square yard, and

it serves to keep the granular material and underlying soil separated. This

results in better performance of the undercut.

When the depth of the undercut is 24 inches or greater, consider using a

geogrid to reduce the depth of the undercut.

For undercuts 12 to 16 inches deep, place a geotextile in the bottom,

then the geogrid, and then the granular material. For undercuts 16 inches deep and greater,

place the geotextile in the bottom, then half the granular material, the

geogrid, and then the rest of the granular material. For severe situations, you can use multiple

layers of geotextile and geogrids.

Consult with the Office of Geotechnical Engineering in these cases.

Chemical Stabilization of the

Subgrade

Item 206

Chemically Stabilized Subgrade can be used to treat unstable

subgrades. Lime or cement is typically

used, but lime kiln dust is another option.

Lime is used for A-6b

(silty/clay) or A-7-6 (clay) soils which have a plasticity index of 20 or

greater. As a general guideline, use 5 percent lime by dry weight of the soil,

assuming a dry weight of 110 pounds per cubic foot.

Cement can be used to treat

unstable subgrades consisting of A-3 (fine sand, coarse and fine sand), A-2-4

through 7 (gravels), A-4a (sand silt), A-6a (silt and clay), A-6b (silty clay),

or A-7-6 (clay) which have a plasticity index less than 20. As a general guideline, use 6 percent cement

by dry weight of the soil assuming a dry weight of 110 pounds per cubic

foot.

Lime kiln dust can be used

for soils which have a plasticity index in the range of 10 to 20. Consult with

the Office of Geotechnical Engineering when using lime kiln dust.

See Item 206,

Chemically Stabilized Subgrade, of this manual.

Implementation during Construction

Once the type of

stabilization treatment has been chosen, constant monitoring of the construction

is required to adjust the treatment to meet the field conditions. Soil conditions always vary; they vary the

most on rehabilitation projects or in cuts.

If the undercut option is

chosen, the project should monitor the bottom of the cut and evaluate the

condition. Take hand penetrometer

readings at the bottom of the cuts and compare them to the initial test pit or

soil boring information. If the

condition changes from the earlier evaluation of the test pits or the soil

borings, then adjustments to the undercut depth are required.

For undercuts that are 2 feet

deep or greater, give consideration to using geogrid in addition to the

geotextile fabric. The need for geogrid

can be determined by placing approximately half of the undercut depth. Load the undercut with a fully loaded

truck. If the area is unstable, place

the geogrid and continue to fill the undercut.

Once the undercut or

stabilization is complete, proof roll the area to ensure that the final

subgrade meets the rut depth and density requirements as detailed earlier in

section “Failure Criteria.”

Constant vigilance is needed

in order to make the most economical correction. It is easy to over-excavate unnecessarily and

waste money. It is more difficult to

make the right economical choice to stabilize the subgrade and to meet the

design and construction needs.

Documentation Requirements - 204 Subgrade Compaction

and Proof Rolling

1. Materials.

2. Compaction according to S-1015.

3. Lift thickness and roller passes.

4. Equipment used.

5. Type of soils.

6. Verify square yardage.

7. Verify subgrade line and grade.

8. Proof roll and make corrections.

9. Subgrade Test Pit Investigations.

10. Undercut measurements.

11. Document on CA-EW-1,CA-EW-2,CA-EW-3,

CA-EW-8, CA-EW-12 and CA-D-3. Do not

duplicate the information on all forms unless necessary.