506 Static Load Test

Description (506.01)

Static load tests are performed

on piles to determine the accuracy of dynamic load test results and to

determine if the capacity of the pile being tested has increased or decreased

after it has set in the ground for some period of time. The intent of performing the static load test

is to potentially reduce the driven length of pile by fine-tuning the pile

capacity determination. There must be a

substantial amount of piling at a structure to justify the expense of a static

load test. Generally, 10,000 feet of

piling (all of the same size and ultimate bearing value) is the amount required

before specifying a static load test.

Static load tests are not

performed very often and can be complex and must be performed properly for the

results to be useful. Always contact the

Office

of Construction Administration or the Office

of Geotechnical Engineering for assistance before performing a static load

test.

With the 2013 C&MS, the

Department adopted the ASTM

Quick Load Test method for static load testing. The duration of the static

load test using this method is generally 8 to 10 hours. Using the previous method, the test could

take longer than 24 hours. The other significant change with the 2013 C&MS

is that the Contractor is responsible for taking the readings. Previously, the Department was responsible

for taking readings during the test.

Determination of Need

The Office

of Construction Administration or the Office

of Geotechnical Engineering must be consulted before non-performing the

static load test. Consult either of

these two offices to determine if a subsequent static load test should be

performed.

Static load tests are not

performed on piles driven to refusal on bedrock.

General (506.02)

Pile Wall Thickness

Most static load tests are

performed on cast-in-place piles (also called pipe piles or tube piles). The static load test will place a load on the

test pile that is twice the Ultimate Bearing Value (UBV);

therefore, the test pile may need a thicker wall than that required by 507.06

or the Contractor will have to fill the pile with concrete and allow the

concrete to cure for 5 days.

For test piles, if the wall

thickness is less than the required wall thickness given by the equation below,

then the Contractor must fill the pile with concrete and allow the concrete to

cure for 5 days before performing the static load test.

![]()

Where:

t =

Shell wall thickness (inches)

R =

Ultimate Bearing Value, UBV (pounds)

D =

Diameter of pile (inches)

If the test pile wall

thickness is equal to or greater than the wall thickness given by the above

equation, the Contractor can perform the static load test 72 hours (3 days)

after he has finished driving the test piles and anchor piles. Generally, piles with a diameter of 16 inches

or greater will meet the minimum wall thickness requirement for the test pile. Depending on the UBV,

12-inch and 14-inch piles may not be available with the minimum wall thickness

for test piles. These piles will have to

be filled with concrete before the static load test.

Driving Test Piles

The test pile can be, and

usually is, a production pile. The test

pile must be vertical. Sometimes people are concerned about “failing” a

production pile. This should not be a concern.

In fact, it is desirable to “fail” the test pile as when this happens,

we determine the true capacity of the pile and achieve the most value from the

test. In the case where a test pile,

which is also a production pile, “fails” during the static load test at a

capacity lower than required, the solution is usually as simple as splicing on

more pile length and driving the pile deeper.

The standard plan note for a

static load test requires the Contractor to drive four piles, not including the

anchor piles. The first two driven piles

are test piles. Each one is driven to

the required UBV as determined by the dynamic load

test. This means both of these piles are

dynamic load tested (that is one dynamic load test item). Do not overdrive these first two piles. Perform the static load test on one of these

two piles. If the first pile is not

suitable to use for the static load test, the second pile is driven as a

backup. The dynamic load test on the

second pile gives additional data that can be used to interpret the static load

test results. The third and fourth piles

are driven to reduced blow counts 75 and 85 percent of the driving criteria.

For example, if the driving criteria from the dynamic load

test is 40 blows per foot (bpf), then the

third pile is driven to 30 bpf (0.75 × 40), and the

fourth pile is driven to 34 bpf (0.85 × 40). It is important that the third and fourth

piles be shorter than the test pile, so the person interpreting the test data

can make an accurate evaluation. The

exact method of determining shorter length is not critical. They can also be driven to 75 and 85 percent

of the length, or some other lengths shorter than the test pile. The third and fourth piles are also dynamic

load tested (one more dynamic load test item).

In some soil, piles will gain

capacity with time. This is called pile set-up or sometimes, pile freeze. The reduced capacity piles are driven to see

if the pile will gain enough capacity with time to meet the Ultimate Bearing

Value requirement. If there is some

increase in capacity, but not enough to meet the UBV,

then we can still estimate the appropriate driving criteria if we know the

amount of pile set-up. To do this, we

need to know the capacity at the end of the initial pile driving, which we can

determine from the dynamic load test.

This is why we dynamic load test the reduced capacity piles.

Anchor Piles

Production piles can be used

as anchor piles. Vertical piles are

preferred for the anchor piles, but the Contractor may use battered piles for

the anchor piles as long as the battered piles are symmetric around the test

pile. The Contractor determines the

number of piles to use as anchor piles and the required length of

penetration. Anchor piles must be at

least 8 feet (2.5 m) from the test pile, measured from center-to-center. If the anchor piles are also production

piles, they may need to be re-driven to the required driving criteria after the

static load test, depending on the test results.

Generally, the test pile

should be driven before the anchor piles, but this is not required. If the anchor piles were driven first and

there was a problem with the first test pile so that the backup test pile had

to be tested, then the Contractor would have to drive additional anchor piles

around the backup test pile.

No other production piles are

to be driven until after the results of the static load test have been interpreted.

However, the Engineer can allow the Contractor to proceed with pile driving at

his own risk, with the understanding that the Department will not pay for

piling driven deeper than required based on an evaluation of the static load

test results.

Application of Load (506.03)

The Contractor must wait at

least 72 hours (3 days) after driving the test pile and anchor piles before

applying the test load. If the

Contractor has filled the test pile with concrete because it does not meet the

minimum wall thickness requirement, then the Contractor must wait 5 days before

applying the test load. The plan notes

may require a longer waiting period.

The test pile should be cut

off as near to the ground as practical and the jack placed along the axis of

the pile with full bearing on the required load cell and bearing plate.

Instruments

The Contractor must furnish a

set of gauges or devices capable of accurately determining settlement of the

pile to 0.001 inch (0.025 mm) and a calibrated load cell for determining the

load applied. Dial gauges must have

graduations every 0.01 inch (0.25 mm) or less.

The gauges used to measure

the settlement of the pile should be placed opposite each other and should be

placed at the sides of the pile. They

should be supported from posts or fixed objects. The post or fixed objects are to be

independent of the test load set-up and at least 4 feet (1.25 m) away from the

test pile. However, the gauges should be

placed as close to the test pile as possible.

Dial gauges are furnished and should have sufficient travel to measure

up to 2 inches (50 mm). A backup system

is required in case of problems with the gauges. The backup system usually consists of a ruler

applied to the test pile, with a mirror and string line for measuring

settlement.

The primary means of

determining the applied load is a calibrated load cell. The pressure gauge on the hydraulic jack can

be used as a backup load measuring system.

The pressure gauge alone is not accurate enough for the static load

test. Also, if the jack should bind up,

the hydraulic pressure would increase while the load transmitted to the pile

would not necessarily increase.

Loading

The load is to be applied in

increments consisting of a first increment of 1/10 the UBV

of the pile (R). The Contractor records

the dial gauge readings for each gauge 1, 2, 4, 8, and 15 minutes after each

load increment is applied. Calculate the

average pile settlement from the gauge readings. Apply the next load increment after the 15

minute reading.

Maintain the test load during

each load increment. Due to settlement

of the pile, the load and pressure in the jack may decrease with time. The Contractor should run the hydraulic pump

as necessary to maintain the load on the pile.

Continue to increase the test

load until the load is twice the UBV or the pile

reaches plunging failure. Plunging

failure is defined when continuous jacking is required to maintain the test

load.

Unloading

After loading is complete or

plunging failure is reached, unload the pile in five equal decrements in 15

minute intervals. Record the settlement

readings at 1 and 15 minutes after each load decrement. After the entire test

load has been removed from the test pile, record the settlement after 1 and 15

minutes.

If it is necessary to remove

and reapply the load, such as a problem with the jack or load cell, reapply the

test load using the same procedure used to apply the initial loads.

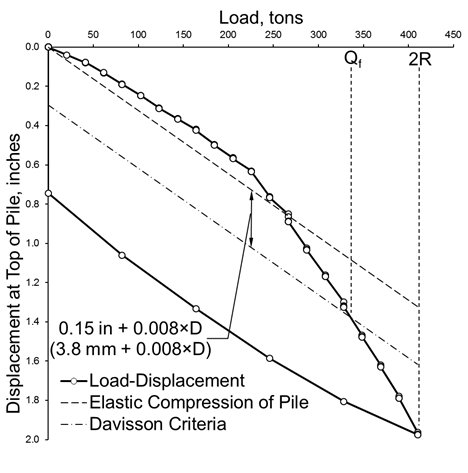

Load Test Results

The test load Ultimate

Bearing Value (Qf)

is the maximum capacity of the test pile.

To determine Qf,

it is necessary to plot the settlement of the top of the pile versus the load

on the pile. Draw a straight line

through the zero point and the theoretical elastic settlement of the pile using

the equation in the specification. This line represents the elastic compression

of the pile (the distance that the pile compresses under the test load). Draw another line parallel to the first, but

offset by the distance given in Equation 506.1. The second line is called the Davisson

criterion line.

0.15 inch + 0.008 D ( 3.8 mm + 0.008D )

Equation

506.1 – Settlement Offset

Where:

D =

Diameter of pile (inches or millimeters)

The

point where the load-settlement curve from the static load test intersects the

Davisson criterion line is the test load Ultimate Bearing Value (Qf). An example from an actual static load test is

shown in Figure 506.A.

In some cases, the slope of

the unloading portion of the curve can be used to determine the elastic

compression of the pile.

If the load-settlement curve

does not intersect the Davisson criterion line, then Qf is equal to the greatest test load

applied (2R).

Figure 506.A

– Load-Settlement Curve

Restrikes

The standard plan note for a

static load test requires the Contractor to restrike the test pile and the two

reduced capacity piles. The note may

require re-striking the backup test pile.

The restrikes are performed at least 7 days after the piles were

driven. Each restrike test consists of

dynamically testing two piles and determining the capacity of the piles. Pile set-up is the increase in capacity for a

pile from the time it was initially driven to the time it was re-struck. Ideally, the capacity from the restrike test

on the test pile should be close to the results of the static load test.

Application of Results

Either the Office

of Construction Administration or the Office

of Geotechnical Engineering will review the pile driving logs, the static

load test results, the dynamic load test results, and the restrike test

results, and then recommend the driving criteria for the production piles. Wait for the recommended driving criteria

before letting the Contractor drive the rest of the production piles. However,

the Engineer can allow the Contractor to proceed with pile driving at his own

risk, with the understanding that the Department will not pay for piling driven

deeper than required based on the recommended driving criteria after the

evaluation of the static load test results.

The static load test results

will apply to the same type and size of piling, driven with the same type of

hammer, to approximately the same depth, with similar driving characteristics

as the test pile.

The pile hammer used for

driving the test pile shall be used for driving all piles represented by the

static load test. If the Contractor

subsequently finds it necessary to use a different size and type of hammer, the

Office

of Geotechnical Engineering or the Office

of Construction Administration will determine if an additional static load

test is required; any such additional static load test shall be completed at no

additional cost to the Department.

Documentation

Requirements - 506 Static Load

Test

Documentation for the static

load test consists of the driving logs of the test piles and reduced capacity

piles, the dynamic load test report, the restrike test report, and the

load-settlement readings from the static load test. Identify the piles using the pile numbering

system on the plans if the piles tested are production piles.