640 Pavement Markings

641 Pavement Markings – General

This information is intended

to serve as a guide for construction personnel where the Contractor furnishes

and installs traffic control marking devices. This information may also be useful

for maintenance personnel performing the same functions.

As per 641.06, the Contractor shall establish

reference points to ensure proper placement of restored markings on projects

where resurfacing or other operations will result in obliteration of the

existing pavement markings.

Please refer to the Traffic

Engineering Manual for a complete list of forms and supplementary

information. Updates are available on the following ODOT website:

Pavement Marking Materials (641.02)

Pavement marking materials

used on the construction projects shall be as listed on the Approved

List.

The Approved List for

pavement marking materials is maintained by the Office of Material Management (OMM) and is available on the website.

http://www.dot.state.oh.us/Divisions/ConstructionMgt/Materials/Pages/PAVEMENT-MARKING-MATERIALS.aspx

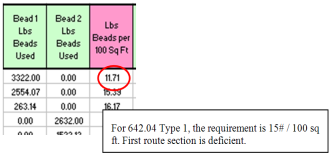

The appropriate type of glass

beads shall be applied according to C&MS 740.09 for different types of pavement marking

materials.

Application of Pavement Marking Materials (641.03)

Pavement marking materials

shall be applied according to C&MS Items 640

and 740.

Data Logging System (DLS)

(641.04)

The Data logger System can be

verified in the field by using the following method:

DLS Verification

Testing

This section provides

information on the Data Logger System (DLS) for

long-line striping trucks, the reports generated by DLS,

and how to use the reports to verify compliance with specifications.

DLS Requirements

The requirements for DLS are contained in C&MS Section 641.04.

According to Item 641.04, long-line striping equipment

for traffic paint, polyester, epoxy, and work zone markings (Item 642) shall be equipped with a computerized

Data Logger System (DLS) to document long-line

markings as follows:

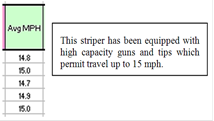

1. Measure and record application vehicle speed to nearest

0.1 mph.

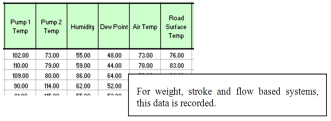

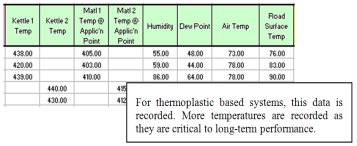

2. Measure and record weight and/or volume amount of

material used by color.

3. Measure and record weight of glass beads.

4. Measure and record pavement surface temperature.

5. Measure and record air temperature.

6. Measure and record dew point.

7. Measure and record humidity.

8. Calculate and record average material application

rates and film thickness over the section painted.

9. ODOT provides

standard DLS spreadsheets which prescribe the

correct DLS report format and content.

DLS are not required for any markings applied by hand,

with push carts, for channelizing lines, or Class II work zone markings.

When the Striping Truck Arrives on the

Project

·

Each district

should establish one individual as District DLS

Contact to receive DLS Reports for all striping

activities. Check with the District Construction Office for the email address

of the District DLS Contact to provide to the

Contractor.

·

Make sure every

vehicle in the striping train has the correct maintenance of traffic equipment

and signs. See SCD

MT-99.20 and plan notes.

·

Check the

driver’s door or the door of the DLS unit to confirm

the presence of the DLS calibration sticker. It

should be signed and carry a date no more than one-year-old. Every DLS must be calibrated once every year.

·

Make sure that

there are adequate TE-24s to cover all materials needed for the job.

·

Make arrangements

with the Contractor’s crew foreman to get DLS Short

Reports for each day’s work. DLS Short Reports are to

be provided to ODOT the next working day or, when requested by ODOT personnel,

any time route sections are completed on any given day. ODOT should receive a

report from the Contractor for each day worked. The DLS

specification requires the Contractor to furnish ODOT with a paper copy of the DLS Short Report which should be retained to compare to the

electronic file that will be received later.

·

The Data Logger

System shall be verified by field personnel.

Field personnel shall randomly verify the components of the DLS. The purpose of

this is to verify that the striping truck places the material shown on the DLS printout. Field

personnel should try to verify the DLS of every paint

contractor at least once per construction season. If field personnel believe that the DLS printouts are not accurate, then more field checks can

be taken.

How to Field Verify the Data Logger System

Figure 640.A – Striping

Truck with DLS System

Figure 640.B – Electronic

Control Box

Figure 640.C – Sensors

Sensors such as temperature sensors,

located at appropriate locations on the striping truck, provide temperature

data.

Figure 640.D – Gauges

Gauges provide data and help monitor the temperatures of striping material

in the tanks.

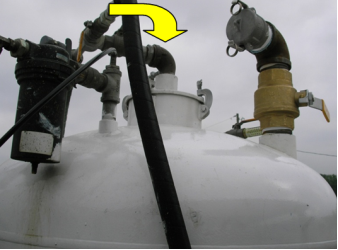

Figure 640.E – Glass Bead

Tank Load Cells

Glass bead tanks are mounted on load cells. Load cells are the basis of bead weight

calculations.

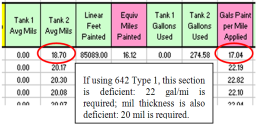

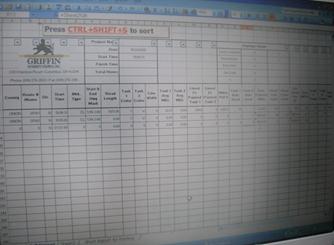

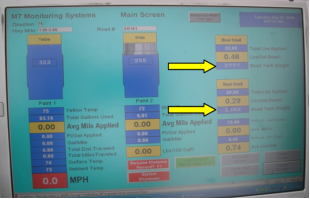

Figure 640.F – DLS Electronic Data Sheet

1. DLS data is automatically recorded and stored

electronically.

2. DLS data includes:

a. Sensor data.

b. Distance data.

c. Ambient conditions.

d. Material quantities.

3. Verification test results will be compared to the

Contractor’s electronic sheet data.

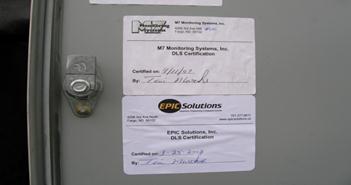

Calibration Sticker

Check

Check for the presence of the

annual calibration sticker.

Figure 640.G – Calibration

Sticker

Evidence of the annual

calibration shall be a signed and affixed sticker to the inside of the driver’s

door of each striping truck.

Yearly Calibration

1. As per C&MS 641.04,

each DLS shall have an annual calibration.

2. Items to be calibrated include:

a. All mechanical and electrical components.

b. Software.

c. Function and output.

3. Calibration will be confirmed by the manufacturer.

The Plate Test

Figure 640.H – The Plate

Test

1. Place an aluminum plate, approximately 24 inches by 8

inches under the paint gun of the striping truck. Aluminum plates are supplied

through the Office

of Materials Management (OMM), Chemical Section.

2. Allow the striping truck to stripe over the plate in

order to get a stripe of the desired thickness on the plate.

3. Send the striped plate to the OMM,

Chemical Section for film thickness testing.

After converting dry film thickness to wet film thickness, the

difference obtained from the plate should be no more than 5 percent from the DLS reading.

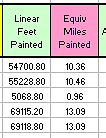

4. Send the Contractor’s DLS

average mils applied data as comparison for the film thickness testing results.

See picture below.

5. Note: Be careful not to damage the paint stripe on the

plate.

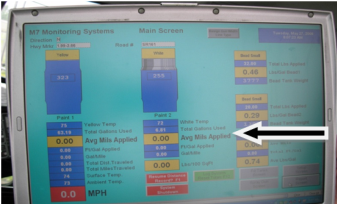

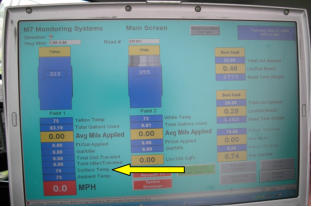

Figure 640.I – Average Mils

Applied

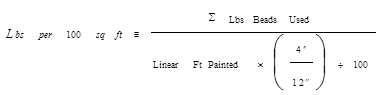

The Bead Weight Test

Figure 640.J – The Bead

Weight Test

1. Check and record the bead weight on the DLS electronic data sheet W1.

2. Obtain an object of known weight. Must be a minimum of

20 pounds (e.g., a 50 pound bag of glass beads).

3. Place the weight on top of the bead tank. Keep the

weight in position on top of the tank and check and record the new weight, W2,

on the DLS electronic data sheet.

Subtract W1 from W2 to get

the known weight of the object used.

W2 – W1 = weight of the

object of known weight used.

Correct test results confirm

the proper operation of the bead tank load cells as well as the accuracy of the

data on the spreadsheet. The difference

should be no more than 5 percent.

Figure 640.K – The Bead

Weight Test

The Infrared

Thermometer Test

Figure 640.L – The Infrared

Thermometer Test

Use a hand-held Infrared Thermometer to measure road surface temperature, air temperature, and/or striping material

temperature.

1. To operate the infrared thermometer, follow the manufacturer’s

operating procedures.

2. Compare temperature readings to the data on the

appropriate DLS electronic screen.

3. Temperature readings on the DLS

screen should be within ±5 percent of the thermometer readings.

Figure 640.M – The Infrared

Thermometer Test

The

Humidity Test

Figure 640.N – The Humidity

Test

1.

Measure the

ambient humidity with the use of a sling hydrometer.

2.

To operate the

sling hydrometer, follow the manufacturer’s operating procedures.

3.

Compare humidity

readings to the data on the appropriate DLS

electronic screen.

4.

Humidity readings

on the DLS screen should be within ±5 percent of the

hydrometer readings.

Figure 640.O – The Humidity

Test

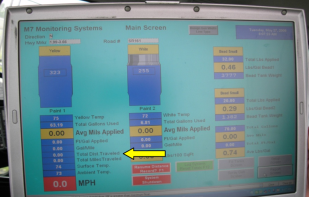

The Distance Traveled Test

Figure 640.P – The Distance

Traveled Test

1. Testing the distance traveled data on the DLS electronic data screen can be done using a distance

wheel like the one shown in the picture.

2. To operate the distance wheel, follow the

manufacturer’s operating procedures.

3. Compare distance readings to the data on the

appropriate DLS electronic screen.

4. Distance readings on the DLS

screen should be within ±5 percent of the distance wheel readings.

5. DLS distance data can also be checked using mile markers

and an accurate odometer.

Figure 640.Q – The Distance

Traveled Test

Summary

1. The specified annual calibration of the data logger

system is the primary check of the operation of the systems.

2. The tests described above are meant to be done in a

random fashion to:

a. Verify proper operation after calibration.

b. Verify correct millages are

applied.

c. Determine if the system is the cause of suspicious

developments in the field application of striping material.

3. One or all of the tests may be used to check the DLS operation.

What to Do When the DLS Fails

DLS Reports

Delivery of DLS Reports

Each district should

establish a District DLS Contact person who will

receive email copies of the DLS Reports and provide

that person’s name and email address at the preconstruction meeting.

The paper copy of the DLS Short Report covering all route sections completed each

day must be provided to ODOT personnel the next working day. A paper copy of

the DLS Short Report may be requested from the

Contractor by ODOT personnel at any time during striping operations for those

route sections completed so far that day. The paper copy of the DLS Short Report should be retained by the project and

compared to the DLS Full Report for the same route

sections, which will be provided to ODOT personnel by the Contractor at a later

time, as described below.

DLS Full Reports contain all project, application, and

environmental data and can be provided to ODOT by any one of the following

methods, which should be agreed upon at the preconstruction meeting:

·

Hand delivery of

paper report.

·

Fax delivery of

paper report.

·

E-mail

an electronic version of the Excel

spreadsheet file.

Within two weeks of the application

date of the markings which require documentation with the DLS,

the Contractor is required to furnish the District DLS

Contact with an electronic version of the Excel spreadsheet file of the DLS Report in ODOT standard DLS

Report format by e-mail at the e-mail address provided at the preconstruction

meeting. Note: This file will contain both the DLS

Full Report and the DLS Short Report on separate

sheet tabs.

At the end of the project,

the Contractor is required to furnish the District DLS

Contact with all DLS Excel spreadsheet files in ODOT

standard DLS Report format. Note: This file will

contain both the DLS Full Report and the DLS Short Report on separate sheet tabs. The Engineer

shall forward the final electronic copy containing the DLS

Long report and the DLS short report to the following

address:

DLS.Report@dot.state.oh.us

DLS Report Security

ODOT has established a method

to monitor accuracy of DLS Reports. This method is

based on comparison of the paper copy DLS Short

Reports for daily production to the DLS Full Report for the same day. Note: The DLS Short Report does not contain all project or

environmental information, but does contain all information necessary to

monitor correct application rates and speed.

The Contractor is required to

provide ODOT personnel with a paper copy of the DLS

Short Report for each day’s production the next working day. ODOT personnel may

also occasionally request a copy of the DLS Short

Report during the day for those route sections completed thus far that day. On

projects with only partial days of striping work, ODOT personnel should request

the DLS Short Report immediately after the Contractor

finishes the striping operation. Printing of the DLS

Short Report soon after completion of the striping operation will minimize the

opportunity for tampering.

ODOT will keep these paper

reports and compare them to the DLS Full Report that

is received later. Any differences in sections, lengths, quantities, or

application rates between the Short Report and Full Report should be considered

suspect and will be investigated more closely. There should be no valid reason

for any differences between these reports beyond the complete listing of route

sections between partial day and full day reports.

Pay Items

Pay items are plan quantity.

If there is a significant variance between the actual and plan quantities, meet

with the ODOT project personnel to address the issue. Please note that per

C&MS Section 641.12,

Method of Measurement, pavement markings are designed, measured, and paid

“end-to-end,” including gaps, intersections, and other sections of pavement not

normally marked. This provision applies to all types of roadways and lines.

The DLS

is used for two purposes, neither of which is to measure pay item quantities:

1. To monitor environmental conditions and material

application parameters, such as temperatures.

2. To monitor actual application rates of marking

materials and glass beads for purposes of determining deficiencies in

accordance with Section 641.11.

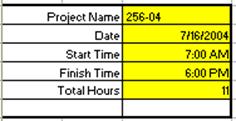

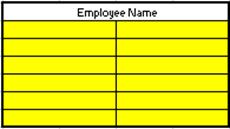

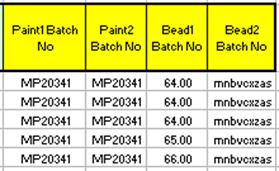

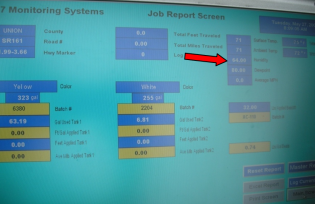

How Data Is Entered

into DLS Reports

Each report has three

different types of cells which are color-coded:

1. One type contains data which may be manually entered

during striping operations (yellow). Note that this information may also be

entered into the job screens of the DLS console and

come into the Report without additional manual entry.

2. One type contains data which must come directly from

the DLS (green).

3. One type contains values that are calculated by the

spreadsheet (rose) from data provided by the DLS.

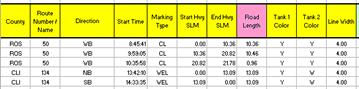

The DLS

Short Report and the DLS Full Report will have one

row for each section painted, by route and by

direction, even if the section length is less than 10 miles. (A route section

is a continuous section of highway without breaks, with the same route number

designation in one direction of travel.) A

new route section is not started at 10 miles if the route and direction stay

the same even when the section length exceeds 10 miles. Whenever material or

beads are loaded, the route section is ended. Start a new route section, for

that route, to complete the route or, if needed, until reloading.

Depending on how the

Contractor sequences work, the route sections will generally match the plan

sub-summary.

How to Read a DLS Report

Check General

Project Information

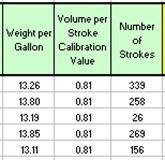

Weight per gallon, per batch,

is entered into the DLS console during job setup for

liquid materials for all DLS types and reported here

as recorded data. Note the weight per gallon may vary per batch.

For stroke-based DLS only, stroke calibration is entered into the DLS console during setup and reported here as recorded

data. The number of strokes is recorded during striping. This information is

used by the DLS to calculate gallons used.

If You Need Further

Assistance

Should it be necessary,

please contact Dan Groh at Central Office Construction, (614) 387-1162 or Maria

Kerestly at the Office of Material Management, (614) 275-1349 for further

assistance.

Construction Inspection during Pavement Marking

Installation

Before the application of

marking material, pavement surface should be clean and dry by using:

1. Power broom.

2. Air jets (guns).

Approve the pre-marking for

long lines and auxiliary markings to ensure proper layout placement.

Center lines shall be “T”

marked to establish no-passing lines.

Figure 640.R – Example of Premarking

District shall provide center

line paint logs.

As per Item 641.06,

the Contractor shall establish reference points to ensure proper placement of

restored markings on projects where resurfacing or other operations will result

in obliteration of the existing pavement markings.

Figure 640.S – Example of

Measurement of Markings

Marking lines shall be

applied to the width specified, ±1/4 inch.

Pavement markings shall be

free of uneven edges, overspray, and other visible defects.

Figure 640.T – Example of

Uneven Edge Line Placement

Pavement marking lines shall

be placed as per SCD TC-73.10 as follows:

1. Edge lines shall be applied 6 inches from the pavement

edge.

2. Lane lines shall be applied 2 inches to left of joint.

3. Center lines shall be applied 2 inches from joint.

Pavement marking lines shall

be straight or smoothly curved true to the alignment of the pavement.

1. If deviation is greater than 3 inches in 100 feet, it

shall be corrected.

Gaps shall be filled that

were not marked as a result of template use for spray-applied auxiliary

markings with marking material after the template is removed.

1. For extruded thermoplastics, gaps may be left.

Figure 640.U – Example of Retroreflectivity Check

Pavement marking lines shall

be sharp, well defined and uniformly retroreflective.

1. To check for retroreflectivity,

put sun over shoulder.

2. If it is not sunny:

a. A well beaded line in the daylight will appear dull.

b. An unbeaded line will be

shiny.

3. If possible, review lines at night for retroreflectivity.