506 Static Load Test

Description (506.01)

Static pile tests are used to determine the accuracy of dynamic load test results, and also determine if the capacity of the pile being tested has increased or decreased after it has set in the ground for some period of time. As a rule, the static load test should not be non-preformed.

Determination of Need

The Office of Structural Engineering must be consulted to determine if a subsequent static load test should be performed.

Bearing

Unless instructed otherwise, the pile to be test loaded is to be driven only to the required blow count as determined by dynamic load tests. Over-driving may result in misleading data.

Anchor Piles

The Contractor determines the number of piles to be used as anchor piles and the penetration obtained. They are not to be closer than 7 feet (2.1 m) center to center to the pile to be loaded and are to be parallel to it. If the anchor piles later are to serve as service piles and are overdriven, the length driven is the pay length. If under-driven, they will need to be re-driven to the required bearing as indicated by the formula, and modified if required by test load results.

Application of Load (506.03)

Unless a longer wait is required by the plans, the test load must not be applied to the pile being tested nor any of the anchor piles until at least 72 hours have elapsed since they were driven. No other service piles for the structure are to be driven until after the results of the loading have been interpreted.

The pile to be tested should be cut off as near to the ground as practical and the jack placed in the axis of the pile with full bearing on the required load cell and bearing plate.

Instruments

The Contractor must furnish a set of gages or devices capable of accurately determining settlement of the pile to 0.001 inch (0.03 mm) and a calibrated load cell for determining the load applied.

The gages or devices used to measure the settlement of the pile should be placed opposite each other and should be placed at the sides of the pile. They should be supported from posts or fixed objects. The post or fixed objects are to be independent of the test load set up and not closer than 4 feet (1.22 m) from the pile to be loaded. However, the gages or devices should be placed as close to the pile to be test-loaded as possible. Dial gages generally are furnished and they should have sufficient travel or gage blocks capable of measuring over 1 inch (25 mm).

The load cell used to determine the load applied does not rely on hydraulic pressure within the pump to determine the load. If the hydraulic pressure within the pump was used to determine the load, and for some reason the pump should bind-up, the hydraulic pressure within the pump would increase while the load transmitted to the pile would not necessarily increase.

Loading

The load is to be applied in increments consisting of a first increment of 1/5 the required capacity of the pile (R) and 1/10 R for each increment thereafter. Measurements indicating settlement of the pile are to be observed and recorded just prior to the application of each increment and immediately after each increment is applied; then every 20 minutes as long as the reading indicates a settlement of 0.01 inch (0.3 mm) or more. Whenever a reading is less than 0.01 inch (0.3 mm) an additional increment must be applied after one hour. Readings do not need to be made during the one-hour wait. At the end of the waiting period, a reading is made and the next increment applied, then repeated as described above.

Completion of Load

The yield point is reached when the pile experiences plunging failure. Plunging failure is defined as when the settlement exceeds 0.03 inch per ton (0.8 mm per tonne) for the increment applied. Whenever plunging failure is reached before the total load exceeds 1.5R, apply an additional increment to determine if the pile again experiences plunging failure. If plunging failure is not repeated, apply additional increments until plunging failure is reached or the total load reaches 2R. If plunging failure is repeated, the yield point is considered to be confirmed.

If the yield point has not been reached and a total load of 2R has been applied, the loading is complete and no additional increments are required.

Unloading

The pile may be unloaded after loading is complete and all measurements have been recorded. Record the net settlement 3 hours after unloading.

If it is necessary to remove and reapply the load, it must be reapplied using the same procedure used to apply the initial loads (except that the load increment must be applied 15 minutes after all measurable settlement has ceased).

Yield Point Reached

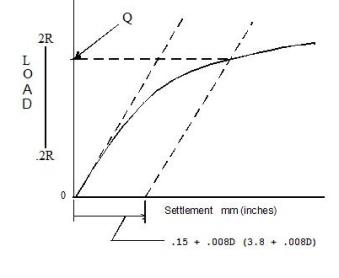

When the yield point is reached, the maximum load that the pile is able to support is the test load ultimate bearing value. To determine the value of the test load ultimate bearing value, it is necessary to plot the settlement versus the load on the pile. Then, draw a straight line parallel to the plotted line. This straight line should be drawn from the zero point and extend through the .2R load value. The straight line should then be offset by the amount derived by Equations 506.1 and 506.2:

|

|

where:

D = diameter of pile (inches)

|

|

where:

D = diameter of pile (mm)

Where the offset line crosses the plotted line, the corresponding load at this point is the ultimate bearing value. See Figure 506.A - Load/Settlement.

Figure 506.A - Load/Settlement

Yield Point Not Reached

If 2R is applied and the yield point is not reached, the test load ultimate bearing value shall be considered as 50 percent of 2R.

Application of Results

Before commencing to drive service piles based on the results of the test load, consult the Office of Structural Engineering for review and recommendations. The complete test load data and the driving log of the loaded pile should be available for this review.

The results of a test load will apply to the same type and size of piling driven with the same type of hammer to approximately the same depth with similar driving characteristics as the test loaded pile.

The hammer used for driving the test-loaded pile shall be used for driving all piles represented by the load test pile. If the Contractor subsequently finds it necessary to use a different size and type of hammer, the Office of Structural Engineering will determine if an additional test load is required; any such additional test load shall be completed at no additional cost to the State.

Records

Documentation shall consist of the driving log of the test-loaded pile identified by the pile numbering system on a piling layout and the test load report.