Typical Stub Abutment Semi Integral Abutment Typical Wall Type Abutment

ABUTMENTS

Typical Stub

Abutment

Semi Integral

Abutment

Typical Wall Type Abutment

Abutments support the ends of the bridge and transfer the loads from the superstructure into the ground. The abutments also support the bearing devices and the backwalls. Abutments are usually constructed of concrete. The abutment seat is the most vulnerable part of the abutment, especially on bridges with leaking expansion joints. The abutment seat is the flat part of the abutment upon which the bearing devices rest. The abutment seat tends to collect moisture and debris which, if allowed to build up, will cause deterioration of the concrete and threaten the stability of the bearings.

There are various types of abutments including wall, stub, integral and semi-integral. The wall type abutment is generally several feet high and extends from the streambed to the bottom of the superstructure. These were generally used on single span bridges in an effort to keep the bridge shorter. Wall type abutments are generally not used now because of their expense.

The stub abutment has been used since the 1960s and is much shorter than the wall type. These are built back away from the stream and up on the back slope, well away from normal water flow. The stub abutment is generally built on piling which is not visible from above ground level. Stub abutments required that the bridge be longer than for wall type abutments, but resulted in more economical bridges that are less vulnerable to flood damage.

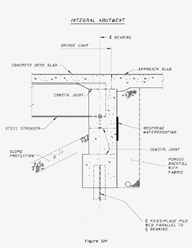

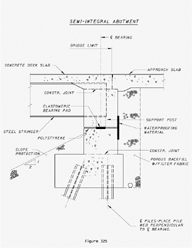

Integral and semi-integral abutments are similar to stub abutments, but instead of having seat areas which support bearings, the abutment actually encases the beam ends. The portion of the abutment which encases the beam ends is isolated from the rest of the abutment with expansion joint material (preformed expansion joint material or polystyrene).

On integral abutments, the upper part of the abutment which encases the beam ends is tied to the bottom part of the abutment with an array of reinforcing steel which allows the upper part to rotate, but not slide.

On semi-integral abutments, the upper part of the abutment is entirely isolated by the expansion material, allowing it to slide on the bottom part of the abutment. Integral abutments were first used in Ohio in the late 1970s and have performed extremely well, requiring no maintenance. Semi-integral abutments have been used in Ohio since the mid 1980s and have also performed well with only minor maintenance needs.

Integral Abutment (click for larger view). |

Semi-Integral Abutment (click for larger view). |

The advantage of utilizing integral or semi-integral abutments is the elimination of expansion joints, backwalls and bearing assemblies. There are also no abutment seats to collect debris and no damage caused by leaking expansion joints. The bridge is restrained from its normal movement due to expansion and contraction by the mass of concrete which encases the beam ends. The only notable effect of restraining the beam ends on integral abutments has been the formation of cracks in the deck at the corners of the bridge, usually at a 45 degree angle. These cracks appear early on in the life of the bridge, but generally do not progress and thus far have not been a problem even in the oldest integral abutment bridges.

Semi-integral abutments allow the upper part of the abutment to move independently of the bottom part. As a result, even though there is no expansion joint directly over the abutment, some semi-integral abutment bridges have had a problem with a joint opening and closing in the pavement at the end of the approach slab. This allows for entry of moisture and debris which may undermine the pavement or approach slab. This opening in the pavement must be kept sealed with a rubberized asphalt crack sealer.

Preventive Maintenance Recommendations:

Wall Type Abutments

- Power wash abutment seats annually after last roadway application of winter dicing salts.

- Seal abutment seats and 3' down face of abutment with silane/siloxane every 5 years, or with epoxy/urethane every 15 years.

Stub Abutments

- Power wash abutment seats annually after last salting.

- Seal abutment seats and face of abutment with silane/siloxane every 5 years, or with epoxy/urethane every 15 years.

Integral Abutments

- No maintenance is required on abutment, but look for 45 degree cracks across corners of deck and seal as part of deck maintenance.

Semi-integral Abutments

- No maintenance is required on abutment, but look for openings in pavement just beyond the approach slab and seal with rubberized asphalt.