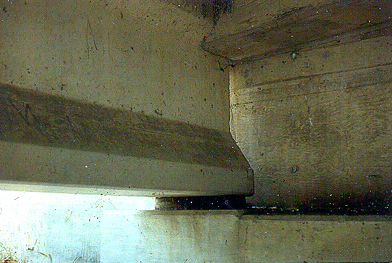

Rocker Bearing.

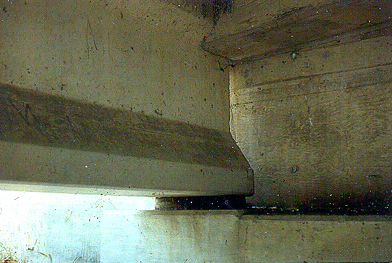

Elastomeric Bearing pad.

BEARINGS

Bearings are the devices that transfer the traffic loading and the weight of the bridge from the superstructure to the substructure. Bearings also allow the bridge to expand and contract, as well as allowing for rotation of the beams as they deflect under live loads. Bearings in Ohio have traditionally been constructed of steel or elastomeric neoprene, or a combination of both. Some bearings act as fixed bearings which anchor the superstructure to the substructure (only allowing rotation), while others allow for expansion and contraction. The ones that allow for expansion and contraction are either sliding, rocker, or roller bearings.

Rocker Bearing. |

Elastomeric Bearing pad. |

Most Interstate-era bridges are continuous over several piers, with one bearing being fixed and the others being moveable (rockers). The oldest movable bearings are generally sliding plate. The Interstate bridges usually incorporated rockers, and bridges built since the late 1970s / early 1980s have been neoprene or neoprene/steel. Some larger bridges have also incorporated Teflon and stainless steel for greater movements. Bearing devices used in Ohio have generally been relatively maintenance-free, with steel requiring the most maintenance and neoprene requiring little or none.

Preventive Maintenance Recommendations: