401 Asphalt

Concrete Pavements – General

General requirements for mix

production and construction of asphalt concrete pavement courses are included

in Item 401. The Contractor

responsibilities in supplying and placing a quality asphalt pavement are

summarized in C&MS

401.01 paragraph 3.

Other specific requirements

for flexible pavement production, quality control, and mix design are included

in Item 402

Asphalt Concrete Mixing Plants, Item 403

Asphalt Concrete Quality Control and Acceptance, and Item 441

Contractor Mix Design and Quality Control - General. Requirements for the specific pavement

courses are found in the specifications under the contract item designation (301,

442,

446,

448

etc.).

The quarterly posting of Supplemental

Specification (SS) 800 on ODOT’s website is used

to update the C&MS. Plan sets list

the SS800

that is in effect for every project.

Check the plan set to ensure you are using the correct SS800

posting since specifications change over time.

Asphalt concrete is a mixture

of aggregate and asphalt material. The

asphalt material used in these mixtures has a relatively high viscosity at

normal temperatures. It is necessary to heat the aggregate and asphalt material

to permit mixing, placing, and compacting.

Asphalt concrete may be used

in new construction as the entire pavement structure or it may be used with

other materials in a layered pavement structure. Extensive use of asphalt concrete is made for

rehabilitating existing pavements by resurfacing or widening and

resurfacing. Asphalt concrete is particularly

adaptable to this type of work, where disruption of normal traffic flow must be

kept to a minimum. Although written with

reference to new construction, the instructions contained herein also apply to

rehabilitation construction.

Asphalt concrete mixtures are

produced in a central proportioning and mixing plant. At the plant, aggregate is dried and heated

to the mixing temperature and combined with the specified asphalt

material. On completion of mixing, the

asphalt mixture is discharged directly into trucks, or conveyed to surge bins

or silos, from which trucks are loaded for transport to the project.

Asphalt concrete is placed by

mechanical pavers. After it is placed, the mixture must be compacted using the

proper compaction equipment before it cools and becomes unworkable.

Item

403.03 requires

the Contractor to provide a FQCS, who is a

company employee who is at the paving site and is responsible for the quality

of the asphalt being placed. The FQCS is

responsible for identifying problems (see C&MS 401.01

paragraph 3) with the placement and immediately works to make corrections. Address all field quality issues with the FQCS and document

all problems and all corrections. When

the FQCS is not

responsive, refer the problem to the Engineer for resolution. An FQCS can have his

approval removed for failure to perform his duties. A list of approved FQCS personnel,

by contractor, can be found on ODOT’s website.

The

Inspector assigned to the placing of asphalt concrete should closely observe

the placing of each type of mixture for indications of deficiencies in the

mixture composition. If the mixture

appears to be deficient in any of the following respects, notify the District

plant monitor and the FQCS immediately,

and note on the Inspector’s Daily Report.

The Engineer should be consulted when there is mix deficiencies that

need addressed. In some cases,

production should cease immediately.

A

Job Mix Formula (JMF) is submitted by the Contractor

using the contract mix specifications for the contract asphalt concrete (446, 448, etc.). The Laboratory must provide conditional

approval of all JMFs before production of any asphalt

concrete. A JMF

is not considered “approved” until it has been used successfully in the

field. The JMF

provides the proportions of the aggregates and Reclaimed Asphalt Pavement

(RAP), Reclaimed Asphalt Shingles (RAS), and binder content, along with the

optimal compaction temperature for the asphalt mix. This information is used in quality control

for production and in field inspection.

The Contractor quality control requirements for asphalt concrete are

provided in Item 403.

Laboratory

personnel must inspect and approve the mixing plant that will be used by the

Contractor prior to the production of any asphalt concrete. Specification Item 402 and Supplement 1101

provides detailed requirements for asphalt mixing plants.

There

are specific requirements for air and surface temperatures in Item 401.06 that must

be met before paving can start. In all

cases, the existing surface to be paved must be dry and with weather conditions

that allow proper handling placement and compaction. Table 401.06-1 provides minimum surface

temperature requirements based on the thickness of the course being

placed.

The

air temperature must be 40 °F for all surface courses. For any surface course using a polymer

modified asphalt binder the surface and air temperature must be at least 50

°F.

This

specification prohibits Contractors from scheduling placement of a surface

course with a polymer modified asphalt binder after November 1, regardless of

the pavement or air temperature.

Although the Department, in certain circumstances, may allow the

placement of a polymer modified surface course after November 1, this practice

should be avoided if at all possible.

Ensure the Engineer has concurred with any decisions that conflict with

this prohibition. Where the Engineer

does allow paving after November 1, ensure the Contractor is taking all

precautions to ensure complete roller coverage before the mix cools below the

laboratory, compaction temperature stated on the approved JMF.

Surface

temperature measurements should be taken using the following procedures:

·

When

taking a reading in the sun, place the thermometer on the pavement and then

shade that area with a clipboard, cardboard, or other available shading

material. Take the temperature reading

after approximately 3 minutes. The

intent is not to shade the area to allow it to cool, but to protect the

thermometer from obtaining a false reading due to direct exposure to the

sun.

·

The

surface temperature should not be taken under the only shade tree or at the

only sunny (unshaded) spot on the project. The surface temperature should be taken at a

representative area.

·

The

surface temperature should be taken in the lane to be paved and not the

adjacent berm.

·

On

Portland cement concrete pavements where flexible repairs have been performed,

the surface temperature of the Portland cement concrete will be the governing

temperature.

·

A

new surface temperature should be taken when the existing pavement surface

material changes (asphalt concrete to Portland cement concrete or vice versa)

to ensure that the new surface meets the minimum temperature

specification. If this specification is

not met, paving operations must be discontinued until the surface reaches

specification temperature. Paving

operations may be moved to a different area of the project where the surface

meets minimum specification temperature.

Placing

thin, surface courses at temperatures near the applicable temperature limits

may require the Contractor to employ special precautions to produce a

satisfactory surface. These precautions

include avoiding paver stops, keeping the rollers close to the paver, adding

additional rollers, and providing proper insulation for the trucks hauling the

material.

It

is the Department’s responsibility to instruct the Contractor to stop paving

operations in the event of rain. It is

the Contractor’s responsibility to stop plant production. If the Contractor will not stop placement,

notify the Engineer.

During

a rain event, a load of material in the process of being dumped into the paver

may be placed with the requirement that the rollers follow closely behind the

paver and a construction joint is formed at the end of the run. Do not allow waiting trucks to be dumped and

placed. The material in the waiting

trucks will retain sufficient heat for proper placing and compacting for an

hour or more depending on the ambient temperature. Water can be kept from accumulating on the

covers of the trucks and draining into the asphalt mixture by raising the truck

beds slightly. These loads may be placed

when conditions improve if the asphalt temperature is acceptable and the

surface being paved is in a reasonably dry condition.

The

Contractor is required to notify the Engineer at least 24 hours before starting

paving on a project. It is a recommended

practice for the Engineer to call for a meeting to discuss the material and

equipment to be used.

Included

in the specifications (401.11) are the

requirements concerning the condition of the vehicles used to haul asphalt

concrete mixtures and the distance the mixture may be transported.

Check

the trucks for compliance with the specifications as they arrive at the paving

site. In particular, look for the

following:

·

The

bed tarp is in good condition and covers the bed. Contact the testing office if any concerns.

·

Small

portions of the load are not isolated from the mass on projections such as

extensions over cabs.

·

The

load is discharged evenly, without surging in the paver hopper, and without

jogging the vehicle when it is in contact with the paver.

·

As

the bed is raised, it does not come in contact with the paver.

·

Uniform

contact between the truck and the paver is maintained as the paver pushes the

truck during unloading.

·

Excess

release agent is not being used on the truck bed.

·

Diesel

fuel is not being used as a release agent.

If diesel is smelled in a load notify your testing office.

·

Insulation

is required when the air temperatures are below 50 °F or haul length exceeds 20

miles, check to see that all trucks are properly insulated and permit only

approved trucks to be loaded.

Notify

the Contractor when deficiencies are found.

When corrections are not satisfactory and difficulties persist, the

vehicle in question should be removed from the project. Contact the testing office with any issues.

The

Contractor is to provide a place off the project for cleaning trucks when

hauling polymer modified asphalt binder mixes or when material is sticking to

the truck bed. If the sticking to the

truck bed is determined to be from excessive cooling of the mix, the Engineer

will require an insulated bed.

Each

load of asphalt is delivered to the project accompanied by a plant ticket with

the load tonnage. The plant ticket must

contain the date; project number; load gross, tare, and net weight; the JMF and material identification; producer name; producer

location or plant number; and the time the truck left the plant. When the load

is accepted at the paving site, the Inspector records the placement location

and initials the ticket.

Asphalt

pavers shall be self-propelled, mechanical spreading and finishing equipment,

provided with a screed assembly capable of distributing the material to the

full width of the lane being paved. The

type of equipment suitable for spreading asphalt concrete depends on the

particular paving operation to be performed: mainline, widening, berm,

intersections, and whether the pavement course to be placed is base,

intermediate, or surface. Spreading

equipment requirements are stated in 401.12.

The

Contractor should use means and methods approved by the asphalt spreader

manufacturer consisting of, but not limited to, any combination of chain

curtains, deflector plates, or other such devices that will eliminate

segregation.

Certain

pavers require modifications. C&MS

Item 401.12 lists the

pavers that require modification. The

Contractor must submit a certification statement to the Engineer which states

that the paver to be used is modified and approved as per 401.12.

Pavers

that leave ridges, indentations, or other marks in the surface shall not be

used. The Engineer shall determine

whether a paver is providing an acceptable asphalt mat that is ready for

compaction. See C&MS 401.01 Paragraph

3.

The

basic types of pavers found in current practice are described in the following

paragraphs.

A

standard asphalt paver consists of a tractor with a receiving hopper, a

conveying and distributing system, and a floating screed. The screed is essentially a rectangular

trowel which floats on the surface of the asphalt mixture. The tractor pulls

the screed by means of two shafts, or arms, hinged to each side of the tractor.

The thickness of placed material is regulated by adjusting the angle of the

screed with respect to the arms. This

adjustment causes the screed to rise or fall until a condition of equilibrium

is reached. Vibrating or tamping devices

on the screed maintain a uniform flow of mixture under the screed. A heating

system is provided to bring the screed to operating temperature at the

beginning of work and to maintain proper screed temperature in cool weather.

The

paver must have an automatic control system that maintains the screed in a

constant position relative to grade, profile, and cross-slope references. These references must be capable of

controlling the screed position independent of irregularities in the underlying

surface and the paver operation.

When

paving in excess of the nominal paver width, only a screed extension with full

auger extensions and the ability to heat should be used. Strike-off plates may only be used on

adjacent berm areas.

Look

for the following items when considering approval:

·

Equipment

must have sufficient size, power, and stability to receive the asphalt concrete

material without erratic operation.

·

Equipment

must be capable of placing the material accurately in regard to line and grade.

·

Asphalt

concrete must be fed uniformly across the width of the screed without surges

(which produce corresponding roughness in the finished surface).

·

Asphalt

concrete mixture behind the screed must have a uniform appearance across the

full width of the course.

It

is the Contractor’s responsibility to make any necessary adjustments in the

paver operation. The Inspector, however,

should be familiar with the working of the paver, the effect of wear on paver

operation, and the effect of various paver adjustments on the placing

operation.

Where

the use of a standard paver cannot be used due to irregular areas or size,

special paver types can be approved by the Engineer. One type is the offset blade strike-off

paver. This type of paver has a

receiving hopper that feeds asphalt to a side-mounted strike-off blade. The tractor to which the hopper is attached

operates on the surface adjacent to the area being paved. The blade is attached to the tractor and can

be adjusted for width, elevation, and cross-slope. These pavers are used to place asphalt

concrete for pavement widening, berm paving, pavement repairs, and other

applications where a relatively narrow width is to be placed.

Compaction

of asphalt concrete is governed by 401.16, 446.05, or 448.03 depending on the contract item

designation. Item 446 is accepted

by density testing and the roller selection is at the discretion of the

Contractor, not governed by 401.13. This is also the case for 448, when it is

accepted by field density testing using Supplement 1055. Acceptance by density testing allows the

Contractor to select the type and number of rollers needed to obtain proper

compaction, and thus, receive full compensation. When compliance with 401.13 is not

required, rollers must be inspected for general working condition, leaks, and

suitability. The Department retains the

right to reject the use of rollers which are not in good repair or are not

designed to do the required work fully and satisfactorily.

Where

Item 448 is not

accepted by density testing, and for Items 301 and 302 Asphalt Concrete Base,

the requirements of 401.13 apply.

For

asphalt concrete items requiring compliance with item 401.13, all rollers must be

inspected for conformance with the specifications before paving begins.

Steel

drums and rubber tires used for compaction should have the necessary

accessories to prevent adhesion to the mixture. They should be kept moistened

with water, water containing a detergent, or water containing an approved

release agent. Excessive use of liquid

should be prohibited.

Pneumatic

tire rollers must be self-propelled, reversible units with vertical oscillation

on all wheels, on at least one axle. The

Contractor should determine the tire inflation pressure necessary to meet the

specified minimum contact area and contact pressure requirements. The Contractor should furnish the tire

manufacturer’s charts or tabulations to the Engineer for verification of the

required inflation pressure. Tire

inflation pressure should be maintained within 5 pounds per square inch (35 kPa) of the required pressure.

Approval

of specialized equipment proposed for compaction, in areas inaccessible to the

specified rollers, should be based on obtaining equal results.

Tables

401.13-1 through 401.13-3 list the specific requirements for rollers.

TABLE

401.13-1 ROLLER CAPACITY

TABLE

401.13-2 STEEL WHEEL ROLLERS

TABLE

401.13-3 PNEUMATIC TIRE ROLLERS

The

surface on which an asphalt concrete course is to be placed must be free from

material accumulations that would contaminate the mixture, prevent bonding, or

interfere with placing operations. The

surface of the existing pavement should be inspected before the paving

operation begins, and should be cleaned of all foreign material, particularly

dust, in accordance with 401.14. The surface should be checked a short

distance in front of the paver to ensure that the surface has not become

contaminated during the construction operation.

A dirty or very dusty surface reduces the ability of the tack coat to

bond, resulting in a potential slippage plane between the existing surface and

the asphalt overlay.

Prior

to placing asphalt concrete on a pavement course constructed under the same

contract, the condition of this previously approved work should be

inspected. Where the approved subgrade

or pavement course has become loosened, rutted, or otherwise defective, the

deficiency must be corrected before the placing of a subsequent course is

permitted. Hauling of materials over an

asphalt concrete base course, for example, may cause cracking when there is not

sufficient pavement thickness to carry heavy loads or where excessive

deflection occurs over soft areas developed in the subgrade. Where cracking of the pavement occurs in such

a case, the strength due to slab action is destroyed, and the affected material

must be removed and replaced after correcting the cause of the failure.

A

tack coat is applied to an existing surface and to a new asphalt surface in

preparation for the next course. Tack

materials are asphalt emulsions conforming to C&MS Item 702. The following types are allowed 702.04 RS-1,

SS-1, SS-1H, CRS-1, CSS-1 or CSS-1H, or 702.13.

The

plans will indicate where tack is to be placed.

In the case where the plans do not specify tack between an intermediate

and surface course, this specification makes that application a requirement.

The

specification requires all vertical faces that will be in contact with an

asphalt course to be coated with asphalt material of a type specified in 401.03

in order to improve the bond to the new asphalt concrete course. This includes gutters, curbs, catch basin

castings, etc., and the vertical face of an existing pavement. Due to the small quantity of material

involved, approval of the asphalt material for this purpose may be based on

field inspection. The results of this

inspection are recorded on the Inspector’s Daily Report, with the material

identified as to type, grade, manufacturer, and quantity used.

In

some resurfacing contracts, a quantity of asphalt concrete may be specified in

the plans for making spot corrections, or for placing a continuous intermediate

course to correct the cross-slope and profile of the existing pavement, as

directed by the Engineer. This operation

should be controlled closely to ensure that the best possible riding quality is

obtained in the completed pavement.

Spot

corrections, when provided for in the plans, are made to correct irregularities

such as cross-slope or profile problems.

Spot corrections can include a leveling or “scratch” course. These corrections are made prior to placing

the intermediate or surface course.

Unless specifically detailed on the plans, the Engineer will locate

deficiencies in the existing surface requiring spot correction and notify the

Contractor of the required corrective measures.

Interior edges of spot patching may be irregular, but outside edges must

conform to the specified edge alignment.

All spot corrective work must be completed to the satisfaction of the

Engineer before the intermediate or surface course is placed.

Intermediate

course of asphalt concrete can be specified to correct minor irregularities in

the existing pavement surface. Spot correction may be needed prior to placing

the intermediate course. The intermediate course should not be used to correct

major deficiencies. Inspect the placing

of the intermediate course to assure that all deficiencies have been corrected

satisfactorily. For intermediate courses

where the profile or cross-slope is not specified on the plans, the profile of

the new course should provide for a smooth riding surface, and the cross-slope

should be uniform on all tangent sections and should vary uniformly in

transition sections into superelevated sections. For an intermediate course where the profile

or cross-slope is specified, the new course should conform to the required

profile and cross-slope, within the specified limits. The procedure for checking the profile and

cross-slope is given in Section 401.19.

During

asphalt paving, careful observation of the mat behind the paver and the rollers

is required to ensure a quality and durable finished pavement. The Contractor’s FQCS is

responsible for the entire paving operation from surface preparation to

paving. The Contractor is required to

control and take prompt corrective action when the mat being placed is not free

of any defect within that Contractor’s control.

Any deficiency in the mat should be brought to the attention of the FQCS. Record the deficiency and the action taken by

the FQCS. If the FQCS does not

make changes to remedy the defects, notify the Engineer. An FQCS can have his

approval removed for failure to perform his duties. The following examples are

defects or problems during pavement preparation or paving that should be

observed and corrected.

Tack

coats are used to bond asphalt layers together to create a monolithic pavement

structure. All of the pavement layers

need to act as one in order to effectively resist the shear and tensile

stresses induced by traffic. The tack

coat keeps the pavement layers from sliding over one another and prevents layer

delamination. If the tack coat is

insufficient, the pavement life will be reduced. The proper application of tack coat is often

overlooked in the field.

Tack

must be applied in a fine, even spray that covers the entire pavement. Tack application that appears “stringy,”

spider-webbed,” streaked, or ridged is unacceptable and should not be included

for pay. Refer to Item 407 in the MOP.

Pavements

to be tacked must be properly cleaned using power brooming

or street sweeping. Where surfaces have

been milled, residual dust is a major problem, thus, creating a bond breaker

between the existing asphalt and the tack coat.

This leads to excessive truck tire pick-up. Additionally, the tack coat must be given

time to “cure” so tire pick-up is minimized.

Picture

401.15.A&B – Improper Tack Application

Picture

401.15.C – Uniform Tack Coverage

Segregation

can be caused by asphalt plant processes, improper truck loading, hand placing

and raking, and paver operation. Segregated areas are susceptible to raveling

over time and rapid pavement deterioration.

Only a dense, uniform surface texture is acceptable.

When

an asphalt mat is segregated, the coated coarse and fine aggregate particles

physically separate from each other.

Segregation can appear in a cyclical pattern or randomly across the mat. The aggregate in the mat should appear to be

uniformly graded in size from coarse to fine, behind the paver, in the finished

mat.

End-of-load

segregation occurs as cyclical V-shaped or chevron type patches in the

mat. This type of segregation is a

result of improper truck loading operation at the plant that results in the

large aggregate separating from the fine aggregate in the truck bed. This generally can be controlled by changing

loading operations at the plant.

Segregation

must be controlled by the Contractor.

The FQCS is

responsible for making changes to eliminate segregation in the mat. If the FQCS does not

make changes to remedy the defects, notify the Engineer. An FQCS can have his

approval removed for failure to perform his duties.

Picture

401.15.D&E – Examples of Segregated Mats

Picture

401.15.F&G – End of Load Segregation

The

asphalt mixture should have sufficient cohesion to remain mounded in the

vehicle during hauling, but should flow freely from the vehicle when the load

is dumped. Bumping or stopping the paver

between loads, as well as uneven flow of material into the paver hopper, will

likely leave bumps in the finished mat.

Trucks backing up to the paver hopper should never bump the paver; the

paver should move to the truck and make contact with the rear tires. During paving, asphalt should flow uniformly

from the truck into the hopper with the quantity in the hopper being maintained

at a constant level. Sudden surges cause

surface irregularities.

The

mat should have a uniform appearance across the width placed. Streaks of differing texture and pulling or

tearing of the mixture generally indicate the need for adjustments to the paver

screed and extensions. Worn screed

plates can also cause streaking behind the paver. Other causes can include low mix temperatures

and mix problems. In all cases, the FQCS is required

to make changes to correct deficiencies.

If the FQCS does not

make changes to remedy the defects, notify the Engineer. An FQCS can have his

approval removed for failure to perform his duties.

Picture

401.15.H&I – Lack of Mat Uniformity and Texture Problems

Picture

401.15.J&K – Screed Mark from Stopped Paver (left) and Pulling and Tearing

of Mat (right)

The

mixture should have sufficient stability under the rollers without excessive

displacement and movement. A bow wave in

front of a roller drum is indication that the material is not stable. Resultant small, transverse cracks after

rolling are also indication that the material is tender. Roller marks may also be an indication of an

unstable mix.

Picture

401.15.L&M - Roller “Checking” Caused by Unstable Material

Picture

401.15.N&O - Roller Marks Remaining in an Unstable Material

Asphalt

binder is used to bind the aggregate particles together. The mixture should contain enough PG

(asphalt) binder without producing a glazed or flushed appearance under the

action of roller compaction. A flushed

asphalt pavement may contain too much asphalt binder.

Another

cause of a flushed or glazed surface can be a result of opening to traffic too

soon, particularly on hot summer days.

The action of traffic tires on the hot surface can draw the liquid

asphalt binder to the surface causing a shiny, glazed appearance. Traffic

should not be permitted on a completed surface course until the mixture has

cooled sufficiently.

Picture

401.15.P&Q - Glazing or Flushing

All

asphalt paving compaction must be completed before the mixture cools below a

workable temperature, generally 175 °F to 225 °F. During inspection, the temperature of the

asphalt delivered to the paver, and immediately behind the paver, must be close

to the optimal compaction temperature as listed on the approved JMF. In the case of

foamed Warm Mix Asphalt this may be, in general, 0 to 30 °F less than the JMF

compaction temperature. The breakdown

roller (first roller) must compact the mat at, or near, this temperature. Complete coverage of the breakdown roller

across the mat is required to obtain uniform density. Lower compaction temperatures are directly

related to an increase in air void content, which increase the permeability of

the pavement. A high permeability

pavement will fail prematurely unless specifically designed to be permeable.

Even with a perfect mix design, if the mix is not properly compacted in the

field, the final product will not last for its intended length of time.

Thin

lift asphalt is susceptible to rapid loss of heat, and its temperature must be

monitored very closely, particularly during cool weather paving.

Any

mixture that cools before it can be compacted properly should be removed and

replaced.

Monitor

and record the mix temperature on a regular basis throughout the paving

operation.

Asphalt

delivery trucks are not allowed to clean out truck beds on the pavement that

will be paved. The material that remains

in truck beds is cold and will not compact correctly, often causing a bump in

the pavement, and likely, a future pot hole.

Spreading or broadcasting the cold material across the pavement prior to

paving does not solve the problem.

Always have the Contractor designate a cleanout area and ensure truck

drivers are using it. If truck drivers

continue to clean out on the road to be paved, have the FQCS address the

issue.

Picture

401.15.R&S – Trucks Cleaning Out in Front of the Paver

Truck

drivers use release agents to keep asphalt from sticking to truck beds. Diesel fuel is prohibited to be used as a

release agent in truck beds, but its use still occurs on ODOT projects. ODOT allows the use of special asphalt

release agents and maintains a list of approved products on its website. Diesel fuel dissolves the asphalt binder and

causes a soft spot in the asphalt mat, which eventually becomes a pot

hole. Any truck driver using diesel fuel

must be removed from the project. Contact the testing office for assistance if

needed. The FQCS is required

to take action to prevent diesel fuel used as a release agent. Pavement areas affected by diesel fuel should

be corrected by removing the contaminated material and replacing it with

acceptable material. Note: the overuse

of approved release agents can damage new pavement. Observe truck loading at the asphalt plant to

ensure there is no free liquid draining from truck beds as a result of over

application of any approved release agent.

Picture

401.15.T&U - Soft Spots in the Mat as a Result of Diesel Fuel used as a

Release Agent

Variations

in the moisture content of the aggregate fed to the plant, or an erratic

production rate, may result in an excess of moisture in the asphalt concrete

mixture. This can cause slumped or

flattened loads accompanied by considerable bubbling or steaming of the

mixture. In extreme cases, the PG binder

material may separate from the aggregate and collect in a film over the surface

of the load. This condition is

unacceptable and is sufficient cause for rejection of the load. Excess moisture may cause streaks of excess

PG binder material to appear as the mixture is spread. Report moisture problems to the Plant Monitor

and the FQCS.

An

asphalt concrete mixture can become unsatisfactory due to contamination of the

PG binder material, the aggregate, or the mixture itself. Contamination of the PG binder material,

either in shipment or in storage at the plant, has the most serious

effects. Contamination of the PG binder

material may remain undetected until a quantity of mix is produced, at which

time a marked change in the odor, consistency, or appearance of the mixture in

the truck or in the paver hopper indicates that contamination has

occurred. When these changes are noted,

observe the mixture carefully as it is being placed and compacted. Report changes in the mixture to the FQCS and ensure

there is follow-up.

When

nighttime paving is required, no work can proceed without an approved and

operating lighting system. This work consists of furnishing, installing,

operating, maintaining, moving, and removing nighttime lighting to illuminate

construction work areas for night work.

Night work is defined as work performed from 30 minutes before sunset to

30 minutes after sunrise.

An

illuminated zone of at least 5-foot-candles is required in the immediate

vicinity of all paving equipment and at least 1-foot-candle at 25 feet. Item 401.15 provides these specific

requirements. The Engineer must approve

the lighting system based on measured luminance readings. The Contractor must provide a photometer that

can measure the luminance levels at the specified foot-candles with

measurements taken 20 inches above the roadway.

Luminance

measurements can be required by the Contractor at any time as requested by the

Engineer. The Contractor must provide

luminance readings at any change in the approved lighting configuration. Any corrections and deficiencies must be made

within 1 hour or the Engineer is required to shut down the construction.

Light

sources shall be positioned so they do not interfere with, impede, or cause

glare for motorists. Light cannot be

pointed at adjacent properties.

Luminaires must be kept clean and bulbs replaced immediately. Asphalt pavement placed during nighttime

operations should be reviewed and inspected in the daylight for mat problems

like segregation, smoothness, etc. The

results and observations of daylight reviews should be used to make corrections

and adjustments to the paving procedures in order to correct and prevent

substandard operations and unacceptable asphalt pavement.

Picture

401.15.V&W - Night Paving Lighting

Many

jobs require paving during night hours to avoid lane restrictions during peak

traffic hours. The Department maintains

a website that details those roadways that cannot have lane closures during

daylight hours. It can be difficult to

see mat deficiencies (e.g., segregation) during night paving due to limited

lighting and shadowing. Undetected segregation has been known to be a problem;

therefore, the Department requires the use of an MTV/MTD

with paver hopper insert or remixing paver for night paving under the following

conditions:

The

project plans include more than 1 mile of continuous paving (measured through

the bridges) and the surface course is being paved.

Or

for intermediate course paving when PN 401 is

included in the project proposal.

An

MTV, MTD, or remixing paver must be a machine

specifically made to eliminate segregation of asphalt mats. There are MTVs and MTDs that merely transfer material from the truck to the

paver and do not mechanically remix the material prior to discharge to the

paver hopper. These machines are not

allowed. The Contractor must provide

manufacturer’s information to prove that the MTV/MTD

proposed for use on the project has a mixer/agitator mechanism that consists of

either segmented, anti-segregation, re-mixing augers, or two full-length

longitudinal paddle mixers specifically designed for the purpose of re-mixing. Longitudinal paddle mixers shall be located

in the paver hopper insert.

Remixing

pavers specifically made to eliminate asphalt segregation are acceptable

alternatives to an MTV/MTD.

In

all cases, the selected equipment must eliminate segregation, provide a uniform

temperature throughout the mixture, and limit temperature differentials to less

than 25 °F (14 °C) across the mat.

Before

the start of paving, the Contractor shall provide a method for measuring the

mat temperature differentials, and a method of inspection for segregation, that

will be used during paving operations.

Measuring mat temperatures can be performed using an infrared thermometer

or special equipment specifically designed for this purpose, such as the Pave IR system. There

should be a regular daylight inspection of the mat placed the previous night to

ensure there are no areas of segregation that could not be seen during night

paving operations.

Equipment

that that does not consistently eliminate physical segregation and/or does not

meet the temperature differential requirement should not be used on the

project. Notify the FQCS of

deficiencies of the equipment and ensure a remedy is put in place.

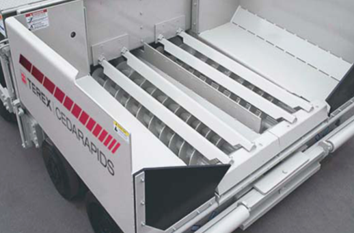

Picture

401.15.X&Y - Remixing Paver (Left) and Material Transfer Vehicle (Right)

Specification

Item 401.15 requires

the Contractor to, “Remove and replace, or otherwise correct, any portion of

the pavement course found to be defective in surface texture or composition

before or after compaction in a manner satisfactory to the Engineer.” The

Engineer will make a determination about whether a defective pavement must be

removed or can remain in place with some repairs. The following methods may produce

satisfactory results when the work is properly performed by sufficiently

skilled workers. All corrective methods

must be approved by the Engineer.

Where

removal of material is required or to correct a low area, saw the patch area to

neat lines. Remove the asphalt to the

full-depth of the defective course and coat the surface of the of the patch

area and butt joints with approved tack coat material. Place the new mixture in the prepared patch

area to the proper elevations and compact as required.

When

material must be removed to correct high areas in the surface, use a diamond

grinder. Removal and replacement of the

surface course and a portion of the underlying material may be necessary in

extreme cases.

Minor

segregated areas in which there is insufficient fine aggregate at the surface

can be corrected by a squeegee application of an asphalt binder, of the same

type, used in the mixture. An emulsion

of the asphalt material, along with added fine aggregate, is also effective. Careful use of the squeegee is necessary to

fill the surface voids without leaving a surplus of the sealer on the

surface.

The

compaction of asphalt concrete mixes is currently governed by one of two types

of specifications. A method

specification is used for some asphalt concrete (301, 302, and 448 by 2005

specification and older), while most mix types (446 and 448 by 2008

specification and newer) are governed by a density requirement (446.05 and 448.03). Supplement 1055

details the requirements of density testing for 448 mixtures.

The

Job Mix Formula (JMF) provides the optimal compaction

temperature for the design. The mixture

should be checked frequently to ensure the asphalt is being compacted at or

near that temperature. For foamed Warm

Mix Asphalt this the filed compaction temperature may be 0 to 30 °F less than

that listed on the JMF. For asphalt concrete base pavements, refer to

Items 301 and 302 for minimum allowed mix temperature. In all cases, the mixture should not be

allowed to cool below a workable temperature for adequate compaction (175 °F to

275 °F) and the majority of compaction should be accomplished before the

temperature reaches 225 °F.

This

section applies to all mixes without a density specification. Compaction of an asphalt concrete mixture

using the method specification is performed by using the rollers and methods

specified in 401.13 and 401.16.

The

number and type of rollers proposed for use by the Contractor should be checked

for compliance with 401.13. The calculation for the roller capacity (tons

per hour) should be made by the project personnel. Documentation of the calculations and the

tire manufacturer’s charts or tabulations furnished by the Contractor should be

kept in the project files. As the work

progresses, the placement rate should be checked to ensure that it does not

exceed the combined capacity of the rollers in use. If the placement rate does exceed the roller

capacity, the Contractor must either reduce the rate or use additional rollers.

For

compacting base mixtures, the specifications require at least one steel wheel

and one Type 1 pneumatic tire roller.

This requirement must be met even though the placing rate may indicate

the need for only one roller. The intent

is to ensure that each layer of base mixture will be subjected to the traffic

conditioning effects of pneumatic tire rolling while the mixture has sufficient

retained heat to respond without fracturing.

For

compacting intermediate or surface courses, the specifications require the use

of a three-wheel roller in the breakdown position. Ensure this requirement is met when using a

method specification.

Example:

Roller

capacity and placement rate.

A

contractor is using one 3-wheel roller, one vibratory roller with 66-inch drums

(both vibrating), and one Type 2 pneumatic tire roller to compact a 3-inch

thick mat using material with a Laboratory conversion factor of 2.0 tons per

cubic yard (tons/yd3).

From

Table 401.13-1 the following is the maximum capacity of the rollers the

Contractor will use:

Three

wheel = 700 yd2/hr

Vibratory

roller = 2 drums x 66 in. x (15 yd2/hr/in.

of width) = 1,980 yd2/hr

Type

II pneumatic roller = 700 yd2/hr

Maximum

roller capacity = 700 + 1,980 + 700 = 3,380 yd2/hr

3,380

yd2/hr

x (3 in ÷ 36 yd3/in.3)

= 281.67 yd3/hr

281.67

yd3 x 2.0 tons/yd3 = 563.34 tons per hour maximum

placement rate.

Therefore,

the Contractor is limited to placing a maximum of 563.34 tons per hour using

the rollers brought to the job.

This

section applies to mixes accepted based on a density specification. The Contractor is responsible for determining

the correct roller train to ensure compaction.

For

446 and 448 asphalt

accepted by density testing, only the last four paragraphs of 401.16 are

applicable.

Item

446 mixtures

require the Contractor to meet a specified density target. To determine the density, ten 4-inch cores

are cut from the pavement for each day of paving. The District Test Lab determines the field

density from the cores. The Contractor

can receive a bonus or deduction to the pay item based on the field

densities. Refer to Item 446 for detailed

information on this process.

Supplement 1055

provides the procedure for density testing using a nuclear gauge for 448 mixtures. This process requires the cutting of cores

only to establish the correlation between core density and gauge density. Refer to Item 448 and S1055 for details

on determining density of 448 asphalt

concrete.

Picture

401.16.A – Standard Steel Wheel Vibratory Roller

This

section pertains to the compaction of asphalt concrete mixes using either the

method specification or the density acceptance specification (described

above). The Inspector should refer to

the last four paragraphs of 401.16 to review

the common part of both compaction specifications.

The

optimum compaction conditions are present immediately behind the paver, and the

greatest increase in density per roller pass occurs in this area. It is important that the breakdown roller

follows the paver as closely as possible and obtains full-coverage across the

entire mat width being placed. In

general, roller coverage should begin at the edge and move toward the

centerline, moving longitudinally, and overlapping each roller pass by one-half

of the prior pass. When a longitudinal

joint is being made (i.e., matching a previous course), this joint should be

rolled first and then preceded with the normal rolling pattern. The specified roller pattern should be

repeated uniformly, without abrupt stops or changes in direction, and the

reversing points at the end of the roller runs should be staggered to reduce

the possibility of forming transverse bumps.

Final rolling should remove all tire marks.

Asphalt

pavement joints can be confined or unconfined.

Confined joints occur when the asphalt mixture is placed directly

against a previously placed asphalt pavement or an existing pavement. Unconfined joints are considered loose since

they are not placed against any confining edge or structure. Unconfined edges of the mat should be rolled

using a steel drum roller with the roller drum hanging out over the edge approximately

6 inches.

Longitudinal

joints occur where two lanes are, or will be, joined together. For an unconfined or confined longitudinal

joint, best results are obtained by using a drum vibratory roller operated in

the vibratory mode with the frequency set at maximum. Pneumatic tire rollers should not be used to

do the first pass of an unconfined longitudinal joint.

Picture

401.16.B – Rolling the Unconfined Edge

Picture

401.16.C – Rolling the Longitudinal Joint First

Longitudinal

joints in the surface layer shall correspond with the edges of proposed traffic

lanes. Longitudinal joints in lower

layers shall be offset, as per Standard Construction Drawing

BP-3.1, alternating each side of the edges of traffic lanes

no less than 6 inches (150 mm).

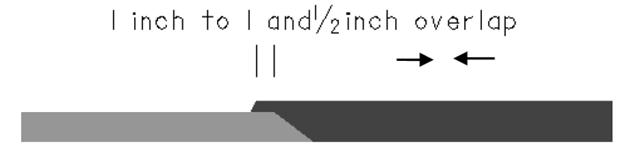

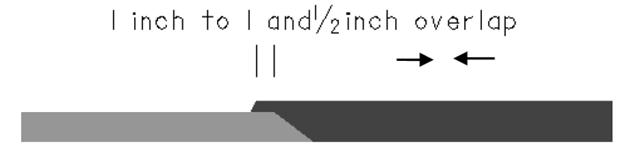

Proper

longitudinal joint construction requires the loose asphalt mixture to be placed

at an extra 25 percent thickness above the confined joint material to allow for

roll down and with a 1-inch to 1-1/2-inch overlap to permit proper

compaction. If the joint is being made

against a sawed or milled vertical edge, the overlap can be around 1/2

inch.

The

height of the new asphalt mixture over the joint must be sufficient to permit

full compaction of the material being placed before the weight of the roller

begins to be carried on the adjacent construction. This pre-compaction height must be maintained

uniformly, particularly on surface courses where raveling of an unsound joint

is likely to occur. Height uniformity is

achieved by continuous, automatic control of the strike off height.

Figure

401.17.A

The

paver should be operated in a straight line to provide a mat with a straight

edge that can be consistently overlapped.

Excessive deviations of the edge line from a straight line are

unacceptable and require trimming the edge before the adjacent material is

placed. With a good edge and proper

control of the placing operation, little or no hand work is needed to form a

good longitudinal joint. The Contractor

should not continuously rake the joint.

On surface courses, the Inspector must be sure that when hand raking

does occur, it does not produce an irregular surface texture.

On

projects where traffic is maintained, the longitudinal joints between adjacent

lanes of surface course pavement must be completed within 24 hours. Where this time limit is exceeded, the joint

should be inspected, and if the joint appears to be excessively rounded or

displaced, trim the face to vertical according to 401.17.

All

cold longitudinal joints are required to be sealed, as specified in 401.17, using a certified PG

binder or SBR Asphalt Emulsion to provide 100 percent

coverage of the joint. Ensure the

correct material is being used. Often

tack is used instead of the required material; this is not acceptable.

Picture

401.17.A – Sealing the Cold Longitudinal Joint

Transverse

joints occur at any time the paving operation is stopped for the day (or

night). When placing the last load of

asphalt for the day, the paver should move forward until all material is

spread. This leaves an irregular end

that should be squared off by hand to form the joint. This joint edge should be compacted

thoroughly, with the rollers passing over the edge, even though this may cause

some rounding or even displacement of the material in the process.

Note

that transverse joints at the beginning or completion of a project require

joint construction, as detailed in the plan sheets, or in accordance with Standard Construction Drawing

BP-3.1.

When

the paving operation resumes, locate the point where the rounding or other

departure from the profile begins, and continue the paving operation from that

location in order to assure a smooth transition from one section to the

other. In some cases, trimming the joint

face may be necessary. For all surface

courses, the transverse construction joint is required to be formed or cut to

vertical. All cold, transverse,

longitudinal joints are required to be sealed as specified in 401.17 using a

certified PG binder, SBR Asphalt Emulsion to provide

100 percent coverage of the joint, or with a certified 702.04 asphalt

material at a rate of 0.25 gallon per square yard (1 L/m2).

The

Contractor must have workers and hot material available during construction of

the transverse joint. Utilize alternate rolling, a 10-foot straightedge, and

the addition or removal of material to produce a uniform profile. Paving operations should not be permitted to

continue until a satisfactory joint has been obtained.

The

specifications require the Contractor to maintain the rate of spreading of a

uniform asphalt course to within ± 5 percent of what is required by the

plan. For a given uniform course, the

Required Placement Rate per Station (RPRS) is

calculated in tons per station and checked against the Actual Placement Rate

(APR). Determine the APR using the plant

weight tickets, which accompany each load of material, and the area covered by

a given number of loads. The area to be

used for the check should not be greater than 500 feet (150 m) in length and

should be measured from the start of a full load of asphalt concrete to the end

of a full load. The results of these

checks should be recorded on Form CA-FP-4, Bituminous Concrete

Inspection.

To

establish the RPRS, the laboratory conversion factor

(tons/yd3) is multiplied by the required volume of the asphalt

pavement per station. One station is

equal to 100 feet. The placement rate,

in tons per station, is given by the following equations:

Calculate

Required Placement Rate per Station, RPRS:

RPRS = [Volume of asphalt in cubic yards (yd3)] x [Lab Conversion

Factor, CF (ton/yd3)]

= [{100

ft. per Station) x Lane Width (ft.) x Mat Thickness (ft.)} ÷ 27 ft3/yd3] x C.F. (tons/yd3)

= tons/station

Calculate

the Actual Placement Rate (APR):

APR

= [Material

Used (Tons) ÷ (Test section length (ft.) ÷ 100 per Station)]

= tons/station

Calculate

the % Difference between the RPRS and the APR:

%

= [1 - (RPRS / APR)] x 100

Where:

RPRS is the required placement rate per station.

APR

is the actual placement rate per station.

C.F.

is the lab conversion factor (tons/yd3).

Example:

Determine

the Required Placing Rate per Station (RPRS):

A

contractor is placing a 5-inch uniform mat of asphalt concrete pavement 12 feet

wide, with a Laboratory conversion factor of 2.0 tons/cubic yard (tons/yd3). In 500 feet the Contractor used 188 tons of

material (from the truck weight tickets).

Is the APR within ± 5 percent of the RPRS?

The

required placing rate (RPRS) in tons of material per

station:

RPRS = [Volume

of asphalt in cubic yards] x [Lab Conversion Factor]

= [{100 ft./station x 12 ft. x (5 in. ÷ 12 in./ft.)} ÷ 27 ft3/yd3] x 2.0 tons/yd3

= 37.04 tons/station

This

rate should be rounded off to two digits after the decimal for control

purposes.

The

APR in tons per station:

APR =

188 tons ¸

(500 ft ¸

100 ft/station) = 37.6 tons/station

%

Difference in Spreading Rate Tolerance:

%

Difference = [1 - (RPRS / APR)] x 100 = [1 – (37.04 ¸

37.6)] x 100 = 1.49%

The

Contractor’s actual spreading rate is within ± 5 percent of the required

spreading rate.

Note: This calculation can also be made on a

tonnage basis instead of the “per station basis.” Simply determine the required tons for the

500 feet and compare it to the actual tons placed.

Tons

required = [500 ft x 12 ft x (5 in ÷ 12 in/ft) ÷ 27 ft3/yd3]

x 2.0 tons/yd3 = 185.19 tons

Tons

used = 188

%

Difference = [1 - (185.19 ¸ 188)] x 100 = 1.49%

When

variations greater than ± 5 percent of the required rate are calculated, the

Inspector should address the variance with the FQCS to determine

a cause. The Contractor should adjust

the paver operation accordingly to bring an unwarranted variation back into

tolerance. The Inspector should

immediately check the actual spreading rate when changes are made to the paving

operation. All variations in tolerance

should be recorded in the Inspector’s daily report.

Depending

on the nature of the material being placed, and quality of the placing

operation, one to four placement rate checks per day normally will represent

the material placed with a given paver.

When the work involves a series of small areas, the use of partial loads

at each location makes the check impractical.

In such cases, the Inspector should determine plan thickness is being

obtained.

The

placing of asphalt concrete should be closely controlled and kept as near as

possible at the specified rate. Even for

a well-controlled operation, both positive and negative variations will

occur. The Contractor should not place

the material at a rate greater than required since this would result in an

overrun of plan quantity for which the Contractor would not be paid. As stated in 401.21, “Method

of Measurement,” the pay quantity is limited to the total weight of the item

placed, converted to cubic yards (cubic meters), with no payment made for the

quantity of material placed which exceeds that calculated from plan lines and

dimensions.

For

all new construction, and some rehabilitation construction, the required

profile grade and pavement elevations are given in the plans. Where a profile grade is not specified for

rehabilitation construction, the profile of the finished pavement surface

depends upon the profile of the existing pavement surface. The plans may require profile correction

prior to placing an overlay pavement; however, profile elevations may or may

not be specified.

For

construction where a profile grade is specified, the Contractor is required to

set grade stakes in order to provide a reference for controlling the elevation

at which the asphalt concrete is placed.

These grade stakes should be set at intervals of no more than 50 feet

(15 m) on tangents and no more than 25 feet (7.5 m) on vertical curves and

transition lengths of superelevated curves. The stakes should be placed on both sides of

the pavement to permit easy checking of the grade; intermediate stakes should

be provided in areas of greater than normal width.

The

specifications require the completed pavement longitudinal profile does not

deviate more than 1/2 inch from the plan elevation at any point. The difference in pavement elevation may be

obtained by methods such as profile levels or differences in rod readings. Prior to placing the surface course, the

Contractor must check the profile of the preceding course at 50-foot intervals

and submit a tabulation of the results to the Engineer for approval. The results should be tabulated in a

convenient form, which list the following:

·

Station

·

Pavement

elevation

·

Plan

elevation

·

Difference

The

Engineer will evaluate the Contractor’s profile check. Approval of the profile and permission to

place the surface course should be based on satisfactory completion of any

corrective work needed for compliance with the profile requirement. The approved profile check will be part of

the project record.

For

all new construction, and some rehabilitation construction, the required cross-

or transverse slope of the asphalt concrete pavement is given either as crown

or as superelevation in the plans. Where a cross-slope is not specified for

rehabilitation construction, the cross-slope of the finished pavement depends

on the cross-slope of the existing pavement surface.

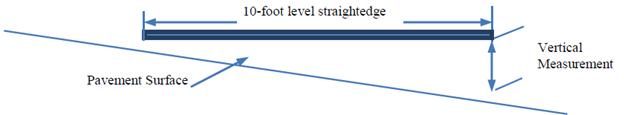

For

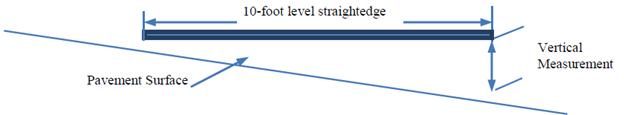

construction where the cross-slope is specified, the pavement cannot vary more

than 3/8 inch in 10 feet from the required slope. The Contractor should check the cross-slope

of the pavement course being placed during the spreading operation with a

10-foot straightedge. The Inspector

should observe this operation regularly to ensure that the pavement course is

being constructed substantially within the specified cross-slope limits.

Particular

attention should be given to the checking of the cross-slope on the asphalt

concrete course preceding the surface course.

Where observation of the Contractor’s checking or additional checking by

the Inspector reveals substantial deviations from the specified limits,

corrections must be made to bring the asphalt concrete course within the specified

cross-slope limits before the surface course can be placed.

Example

of cross-slope check:

The

plan specified the cross-slope as 0.016 foot per foot of pavement width (0.016

ft./ft.). For a 12-foot wide lane, the

pavement drops from the crown to the edge based on the rate of slope. This vertical drop (in inches) is calculated:

0.016

ft./ft. x 12 in./ft. x 12 ft. pavement

width = 2.3 inches

Therefore,

if the Contractor checks the slope with a 10-foot straightedge, the vertical

measurement from the pavement surface to the level straightedge is calculated:

0.016

ft./ft. x 12 in./ft. x 10 ft. straightedge = 1.92 inches

The

spec requires a tolerance of ±3/8 inches (0.375 in.) on the cross-slope, so the

vertical measurement from the pavement surface to the level straightedge can

be:

1.92

in. + 0.375 in. = 2.30 inches

1.92

in. – 0.375 in. = 1.54 inches

Figure

401.19.A

The

required smoothness of asphalt intermediate and surface course cannot exceed

1/4 inch from the testing edge of a 10-foot (3.0 m) straightedge. The Contractor is required to provide a

straightedge that is satisfactory to the Engineer. The Contractor should check the course being

placed while the Inspector observes. The

frequency of checking depends on the nature of the work being done. The surface smoothness should be checked

closely when a transverse joint is being made, when erratic paver operation

occurs, or when hand placing is required in the construction of a transverse

joint. This check is often done at the

end of a paving project since many Contractors elect to use a non-contact

profiler and software per ODOT Supplement 1058.

When

PN 420 or PN 470 is

included, the Contractor is required to check smoothness using approved

profilers and provide an analysis using ProVAL

software according to S1058.

The

project Inspector should determine at the beginning of the project which method

the Contractor will use to check smoothness when PN 402 or PN 470 do not

apply. In the case neither of these

proposal notes apply, ensure that the Contractor is regularly checking the

surface behind the paver with the 10-foot straightedge.

Asphalt

mixture is delivered to the project based on weight in tons for each load. Payment is made in cubic yards for the

specific item of work (e.g., 301, 448, or 446). A conversion from tons to cubic yards is

required. The Laboratory provides a

conversion factor (unit weight/volume) for the specific JMF

being used in tons/cubic yard (tons/yd3).

The

number of tons placed and accepted is converted to cubic yards and compared to

the quantity calculated from the plan lines and dimensions. The Department will not pay for additional

quantities over the plan calculated cubic yards.

After

the total tonnage of material used in a pavement section has been determined,

convert it to cubic yards (cubic meters) using the applicable conversion factor

established in 401.21. The conversion factor of a mix is included on

the JMF and can be obtained from the District test

lab. The tonnage of material used in a

pavement section is converted to cubic yards (cubic meters) as follows:

Cubic

Yards = [TW ÷ CF]

Where:

TW

= Total weight of asphalt placed (tons)

CF

= Conversion factor (tons/yd3)

or (tons/m3)

This

volume should be rounded off to the nearest cubic yard (cubic meter).

Keep

a daily summary that includes Reference Number (Pay Item), Item Number, paving

location, tons used (along with the conversion to cubic yards), and the

calculated pay quantity. Add the asphalt

plant tickets and keep with the daily summary.

Use an adding machine with a paper printout. On the printout write the project number,

date, Reference and Item Number, Participation Code, paving location (route,

station to station, lane, etc.), and show the conversion to cubic yards. Initial the printout and keep with the daily

summary sheet.

Complete

a final summary of the total quantity placed for each Reference Number. The final summary should provide details for

all separate pavement areas. In general,

separate pavement areas include different contract parts, different

participation codes, physically separate roadways, and pavement areas having

differing design sections (e.g., ramps).

The

pay quantity of asphalt concrete with a uniform plan depth is calculated using

the plan width and measured distance along the centerline. Paving in excess of the plan width or plan

length is not eligible for pay. Excess

quantity can only be paid if approved by the Engineer.

Where

one to two courses of asphalt concrete is placed on an existing pavement for

the correction of the profile and cross-section, the depth is variable and the

pay quantity is the quantity placed as directed by the Engineer in accordance

with the intent of the plans. Placement

rate checks, as described in Section 401.21, should be

used to verify that the Contractor is meeting the intent of the plans.

This

section contains general requirements for inspecting and documenting asphalt

concrete pavement operations. The

Inspector should record all observations regarding the placement of the asphalt

mixture, in addition to the following requirements.

1.

Obtain

JMF for the project.

2.

Verify

the FQCS for the

project.

3.

Determine

and document if paver requires modification and has been modified per 401.12.

4.

Check

and document roller capacities as outlined in 401.13 if

required by the specification item.

5.

Document

pavement surface condition, preparation, and surface and air temperatures.

6.

Document

tack or prime used along with source and quantity used versus required. Note if application is non-uniform and steps

taken to correct.

7.

Document

lift thickness, mat width, weather conditions, surface tolerance checks,

equipment problems, mat problems (segregation, tearing, tenderness, etc.),

spreading rate, roller coverage, and any other issues or observations made

during paving operations.

8.

Observe

and document trucks hauling material.

9.

Check

for secured waterproof cover (tarp).

10.

Check

for insulated truck beds for temperatures below 50 °F (10 °C)

and/or if the haul exceeds 20 miles (32 km).

11.

Observe

the asphalt mix in the truck and note any slumping, drain down, or blue smoke.

12.

Determine

compliance with compaction requirements as per 401.16.

13.

Record

asphalt mixture temperatures measured in the paver hopper and on the mat at the

time of compaction.

14.

Determine

and record required and actual placement rates and variance.

15.

Write

location (and route), date, and time on asphalt plant tickets. Tickets should be totaled daily, initialed,

and with the calculator tape attached.

16.

Ensure

samples, cores, or density readings are taken as required by item 446 or 448.

17.

Record

luminance readings for night paving operations.

18.

When

required, determine if MTV meets specification for remixing and mat temperature

differential.

19.

Determine

plan quantity for payment.

20.

Document

on CA-FP-2 through 4

or other approved forms as needed.