202 Removal of Structures and Obstructions

Asbestos Pipe Removal Asbestos on Bridges

Buildings Demolished (Asbestos in Buildings)

Underground Storage Tanks (202.08)

General

Specification Changes

There are several specifications changes to Item 202. The main specification changes and reasons for the changes are as follows:

- All disposal requirements are in 105.16 and 105.17.

- Pavement, base, and wearing course removal Items are better defined.

- Underground storage tank removal requirements are clearly defined.

- Removing all pavements under embankment areas regardless of the embankment height.

- This provides a better embankment foundation and drainage.

- All removal Items of pipe, manhole, catch basins, and head walls are quantified for payment in the plans.

- Even when the new item is in the same location.

- Small Headwalls are paid as ‘Headwall Removed.’

- Full Height Headwalls are paid as ‘Structure Removed.’

- All removals such as pavements, curb, or sidewalks “Above” pipes, manholes, catch basins, and headwalls are quantified for payment in the plans.

- They were incidental in the past.

- Provides better bids.

- A Pay Item for Asbestos Pipe Removed was added.

- The Department has spent over a million dollars cleaning up crushed asbestos pipe.

Pipe Removed (202.04)

General

All significant removals are paid for in the contract. The Department pays for removal of existing pipe if the new installation is over an existing pipe.

When pipes are removed, all removals such as pavements, curb or sidewalks “above” pipe, manholes, catch basins, and headwalls are quantified for payment. These removals were incidental in the past.

The following link describes at least 3 plan notes (P109, P110 and P111):

http://www.dot.state.oh.us/cadd/notes/pavement.not

Plan Note P109

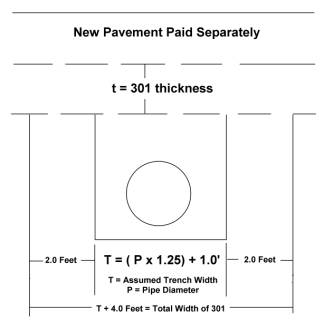

Plan note P-109 details the payment for the 301 Asphalt Concrete Base above a pipe. This note is detailed in Figure 202.1, Pavement Restoration for Pipe Installations (Items 603,605 & 638). The thickness t will be detailed in the plan note. The width of the 301 will be calculated to quantify the 301 for payment.

Figure 0.1 - Plan Note P109 “Pavement Restoration for Pipe Installations (Items 603, 605, & 638)”

Plan Note P110

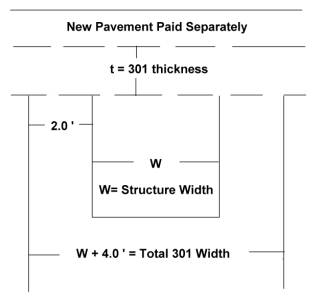

Plan note P-110 details the payment for 301 Asphalt Concrete Base above Drainage Structures. This note is detailed in Figure 202.2 Pavement Restoration for Drainage Structure Installations (Items 604 & 638). The thickness t will be detailed in the plan note. The width of the 301 will be calculated to quantify the 301 for payment. The W shown in Figure 202.2 is the perimeter of the drainage structure.

Figure 0.2 - Plan Note P110 “Pavement Restoration for Drainage Structure Installations (Items 604 & 638)”

Plan Note P111

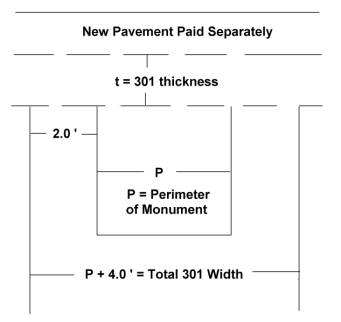

Plan note P-111 details the payment for 301 Asphalt Concrete Base above Monument Assembly Installations. This note is detailed in Figure 202.3 Pavement Restoration for Monument Assembly Installations (Item 604 Monument Assembly). The thickness t will be detailed in the plan note. The width of the 301 will be calculated to quantify the 301 for payment. The P shown in Figure 202.3 is the perimeter of the drainage structure.

Figure 0.3 - Plan Note P111 “Pavement Restoration for Monument Assembly Installations (Item 604)”

All of these notes pay for the asphalt restoration over an installation. The Contractor will be paid for definitive widths in and around these installations. The Department will not pay for the work outside these limits.

Asbestos Pipe (202.04)

Underground concrete pipe manufactured before 1980 can contain asbestos. Mishandling of asbestos pipe may cause significant time delays and increase the cost to the project. One District spent approximately 1.5 million dollars to clean up a crushed asbestos pipe.

Asbestos is not a hazardous waste or a solid waste; it is a special waste. This pipe is regulated and must be removed and disposed of properly. The Office of Production is working on ways to identify this type of pipe, and will try to insert the pay items in the plans. It is difficult to correctly identify these pipes prior to the actual construction excavation.

A description of the pipe removal is in section 202.04 on page 91 in the 2002 CMS.

When evaluating the potential for asbestos in the pipe, the project should look at the "Markings" on the pipe. Concrete underdrain, waterline, and sanitary sewer pipe with the following “Markings” are known to contain asbestos:

Individual utility companies and Local Planning Associations (LPA's) may have used asbestos pipe under their own specifications.

Asbestos Cement Perforated Underdrain Pipe was allowed in 706.15 in the 1970's. In addition, Asbestos Bonded Bituminous Corrugated Steel Pipe and Pipe Arches were allowed in the 1980's in 707.09.

Testing for Asbestos

Test the pipe for asbestos if there is any doubt about the pipe’s composition or identity. When a pipe is suspected of containing asbestos, the project should use the district or central office task order contract to hire a prequalified environmental consultant to test the pipe. Any prequalified consultant that has or can hire a Certified Asbestos Inspector can test the pipe for asbestos.

Asbestos inspectors in Ohio are required to have a certificate of training from an EPA accredited company for Asbestos Building Inspector and Asbestos Management Planner. The certificates are sent to the Ohio Department of Health (ODH) to obtain the required Asbestos Hazard Evaluation license. Both the EPA accredited certificate and the ODH license are required to perform inspections.

Asbestos Contractor Qualifications

There are a multitude of rules, laws, and regulations that govern asbestos operations. One of the best web sites is:

http://www.ehso.com/Asbestos/asbestreg.php

In addition, more information can be found under the Ohio Revised Code 3745-20 or the Ohio Administrative code OAC-3701-34 at the following web site:

http://onlinedocs.andersonpublishing.com/oac/

http://onlinedocs.andersonpublishing.com/revisedcode/

A ‘Certified Asbestos Contractor’ must perform the removal work once it is determined that the pipe contains asbestos. Asbestos removal Contractors need the Asbestos Abatement Project Supervisors certificate for supervisors and Asbestos Worker certification certificates for each worker on the job site.

Asbestos removal Contractors must obtain the Asbestos Hazard Abatement Specialist license or Asbestos Worker License from Ohio Department of Health (ODH). Each asbestos removal company also needs to have an Abatement Contractor license through ODH as well.

The training requirements are under CFR 1926.1101(9)(i-viii) requirements for the truck drivers to haul the asbestos. The only training required for the truckers to haul the asbestos is a two hour OSHA Awareness training.

Asbestos Pipe Removal

It is highly recommended that the Project hire a third party ‘Certified Asbestos Inspector’ to provide oversight during the removal.

Concrete pipe is non-friable asbestos. The pipe becomes friable if it is chipped, crumbles, or crushed during the removal. Therefore, the same requirements are required for friable and non-friable asbestos pipe. Cutting and crushing the asbestos pipe is strictly forbidden. Follow the instructions of the asbestos inspector or contractor.

The project may need to notify the local air quality authority and follow strict OSHA demolition and removal requirements.

The material must be taken to a solid waste facility that is licensed by the Local Health Department. See the boiler plate note listed under 202.04 at the following link:

http://www.dot.state.oh.us/construction/OCA/Specs/SS%20and%20PN%202002/default.htm

Manifesting for disposal is required. The Regulated Waste Project Engineer or the District Environmental Coordinator is required to sign the Manifest for the Department. See Appendix 202 Regulated Waste Requirements, “Manifesting” for more information.

Asbestos on Bridges

For asbestos on bridges, the District Environmental Coordinator (DEC) arranges for an asbestos survey on the bridges. For a typical plan note, see the section, “Typical Regulated Waste Plan Notes”, Asbestos Abatement. This note is similar but not the same as 202 Asbestos Pipe Removal specification requirements in Item 202.

Buildings Demolished (Asbestos in Buildings)

All structures torn down by the Department are required to have an Asbestos Inspection. This is usually done very late in the plan preparation process and sometimes done after the project is sold.

The Office of Real Estate performs these asbestos inspections. An Ohio EPA form ‘Notification of Demolition and Renovation’ must be filled out for the Department.

This form details the type and quantity of asbestos removed and left in the building. Generally, the Asbestos Abatement Contractor performs all of the asbestos removal. In rare cases, the asbestos abatement is performed under the highway contract.

Normally, friable asbestos cannot be left in the building during demolition. In rare cases, the asbestos abatement Contractor may leave a small amount of asbestos in the structure. Of course, large amounts of asbestos cannot be crushed or rendered friable. If the amount of asbestos is small and the ‘Notification of Demolition and Renovation’ allows the building to be demolished, then this material can be hauled away to a Construction and Demolition Land Fill if allowed by the local Board of Health.

If asbestos is left in the building, the building cannot be burned. Even if the Notification of Demolition and Renovation allows the building to be burnt.

The Notice will specifically mark on the form that the building can be burnt. In addition, an Open Burning Permit would be required if the structure is burned.

Burning or disposing of the building is allowed in 105.16 and 105.17. The Contract will specifically state whether burning is restricted due to the asbestos left in the building. This restriction will be based on the ‘asbestos’ remaining in the building, and not on the Ohio Administrative Code (OAC) 3745 in 105.17.

The ‘Notification of Demolition and Renovation’ may be part of the Contract documents so that the Contractor can formulate their bid for disposal.

Ten days prior to the Demolition the Contractor or the District needs to complete this Notice of Demolition form and send it in to the local EPA. The instructions and more details can be found at the following link:

http://www.epa.state.oh.us/dapc/atu/atu.html#Asbestos

Contact the Office of Real Estate, Regulated Waste Project Engineer or District Environmental Coordinator for a clear recommendation on the disposal.

Underground Storage Tanks (202.08)

General

Underground storage tanks (USTs) are one of the most common contamination problems encountered during construction. Section 202.08 of the 2002 CMS details the contract requirements for UST removals. There are four types of UST’s detailed in the specifications:

- Regulated USTs

- Tanks Regulated by the Bureau of Underground Storage Tank Regulation (BUSTR).

- State Fire Marshall regulated tanks.

- Ohio EPA regulated tanks.

- USTs

- Local Board of Health Requirements.

Inspection Services

It is highly recommended that the project hire a BUSTR Certified Inspector to help with the work inspection. This is specialized work, the cost is minimal, and there are environmental requirements that may have changed. The project may need an environmental consultant to review the contractor’s closure report, risk assessment, or remedial action plan. These specialists may be hired by using the district environmental task order contract or by using third party billing through the Contractor.

Contact the District Environmental Coordinator for more specific advice.

BUSTR Requirements

The state fire marshal and OEPA generally follow BUSTR regulations. The State Fire Marshals Office, Bureau of Underground Storage Tank Regulations (BUSTR), controls the vast majority of the installations, uses, and removals of underground storage tanks in Ohio.

See the BUSTR Web site for more information. Valuable information can be found by looking up ‘download’ documents. Additional information can be found by looking at the fact sheets at the following web location:

https://www.com.state.oh.us/odoc/sfm/bustr/Downloads.htm

Project personnel must review the fact sheets and this section of the manual to become familiar with the UST removals.

The types of tanks regulated by BUSTR are detailed on the Fact sheet entitled “What Type of Tanks does BUSTR Regulate”.

If an unidentified underground storage tank is encountered, the Project Engineer should notify the Regulated Waste Project Engineer, District Environmental Coordinator, local fire authority, or BUSTR immediately.

The majority of the UST found in construction are identified in the contract for removal.

Specification and BUSTR Requirements

All required permits, testing, and closure reports are part of the work and are to be included in the bid item price.

Below is a summary of the BUSTR and the specification requirements. The Bureau of Underground Storage Tank Regulations fact sheets should also be used.

- A ‘Certified Installer’ is required for any removal of an UST regulated by BUSTR. The Certified Installers are required to have photo identification. The project engineer should check for this identification. There is a list of the Certified Tank Installers on the web site.

- A ‘Certified Inspector’ is required to inspect the work. This inspector may be from the local fire department, BUSTR, or a consultant who is a Certified Inspector. The Contractor must supply this person as part of the bid work. There is a list of these inspectors on the BUSTR web site.

- A permit must be applied for 30 days prior to the work. The Project Engineer should obtain a copy for the project records. The local fire department or BUSTR may issue the permit. A permit may be required by BUSTR and the local fire department. See the Fact Sheet entitled “The BUSTR Permit Process.” A copy of a permit application is on the web site.

- Even though the permit may be issued by the local fire department, BUSTR must receive a copy of the permit application 30 days prior to the removal.

- Tank registration may be required if the tank is not registered. See the Fact Sheet entitled “Underground Storage Tank Registration”. Since the Department typically is the owner, the District Environmental Coordinator registers the tank. In rare cases the Project Engineer can register the tank. This form is on BUSTR’s web site.

- For unidentified tanks, the owners are typically unknown.

- If a tank was last used prior to 11/8/84, then ownership is the last person who used the tank.

- The local Division of Air Pollution Control of the Ohio EPA may need to be notified because of air pollution concerns. See the Web site location Division of Air Pollution Control in the 105.16 Borrow and Waste “Open Burning”.

- The actual removal is summarized in the Fact Sheet entitled “Closure Guidelines”. See the section on permanent removal and replacement. The Certified Inspector must sign the permit and the project should keep a copy for a permanent record.

- A closure assessment and report is required after the UST removal. The Contractor is required to submit the report to BUSTR within 45 days of the closure. The Regulated Waste Project Engineer should sign the closure report for the Department. The Regulated Waste Project Engineer may elect to have this closure report reviewed by an environmental consultant.

- The District must keep the closure report “Forever”. The report should be given to the Regulated Waste Project Engineer and/or District Environmental Coordinator. The Regulated Waste Project Engineer must ensure that these records are given to the District Environmental Coordinator for final record keeping.

- Depending on the result of the closure assessment, a risk assessment and remedial action may be needed. If these two are required an Environmental Consultant will be needed to perform this work. The task order contract may be used to perform this work. See the Fact Sheets entitled “Risk Assessment”, “Remedial Action Plan Guidelines” and “Selecting an Environmental Consultant” on the web site. Contact the Regulated Waste Project Engineer and/or District Environmental Coordinator.

- The specification requirements in 202.08 do not cover risk assessment, remedial action, environmental cleanup, or the cleanup of the plume beyond a few feet outside the UST. Any of this work should be considered extra work unless additional quantities or other work is described in the plans or proposal.

Other Governing Agencies

Contact the local fire marshal for other UST’s not regulated by BUSTR. For USTs containing hazardous waste contact the Regulated Waste Project Engineer or District Environmental Coordinator (DEC). The Regulated Waste Project Engineer or the DEC needs to contact the OEPA at 614-644-2917.

Releases

The following personnel must be contacted when the UST is removed and 25 gallons or more of petroleum is released, or if the product reaches a body of water or travels off the project site. Project Personnel should use the following web site during a release:

http://www.epa.state.oh.us/derr/ersis/er/er.html

- Immediate Notification:

- Regulated Waste Project Engineer

- District Environmental Coordinator

- Local Fire Department

- The OEPA Emergency Response unit at 800-282-9378

- BUSTR Corrective Action Hotline at 800-686-2878 within 24 hours

- Contact all of the following if a Hazardous chemical in excess of its reportable quantity is released:

- Regulated Waste Project Engineer

- District Environmental Coordinator

- Local Fire Department

- The Ohio EPA at 800-282-9378

Reportable chemical quantities may be between 1 and 500 pounds depending on the chemical. The web site refers to Code of Regulation (CFR) that gives the reportable quantities limits. In addition, it gives explicit instructions about what action should be taken by the project personnel.

The Contractor and the Regulated Waste Project Engineer should know the reportable quantities prior to the UST removal.

At some point, the project should hire an environmental consultant to help with the required paper work.