Appendix 202 Regulated Waste Requirements

Site Specific Health and Safety Plan Requirements

Regulated Waste Designated for Removal in the Contract

Regulated Wastes Found During Construction

Other Wastes and Environmental Considerations

Typical Regulated Waste Plan Notes

Documentation and Critical Inspections

Importance

The Department has experienced contract administration problems during the disposal of regulated wastes, underground storage tanks and asbestos pipe and administrating borrow and waste areas. The main causes of these problems are: the lack of understanding of the regulations, new regulations that govern construction debris, and the infrequency that some of these items are included in the contract. The improper disposal or management of regulated materials can create substantial construction delay problems and a potential future liability to the Department.

The Department has approximately 300 projects in design, construction or completed requiring the disposal of regulated wastes; such as hazardous wastes, solid waste, special waste or petroleum-contaminated soil.

Regulated waste for the purposes of this manual will be defined as a hazardous waste, solid waste, construction and demolition debris, petroleum contaminated soil or any other regulated material denoted for removal under the contract. For further explanation about hazardous waste classifications, types and characteristics see the Hazardous Waste Management Program Manual or other Hazardous Waste Training Manuals.

This section is to be used in conjunction with the Hazardous Waste Management Program Manual (HWMPM) and the handouts and manuals received in the 24 or 40 hour Hazardous Waste Operations and Emergency Response (HAZWOPER) training or the 8 hour HAZWOPER refresher courses.

Additional references also can be found by reviewing the 8 Hour Construction Safety or Construction HAZWOPER manual.

This section does not expand on the technical environmental details explained in these other manuals. This manual should be used as a reference to other manuals when technical details are needed beyond the scope of this manual.

This section replaces the “The Handbook for the Removal of Regulated Waste” dated 04/00.

Responsibility

Project Engineer and Regulated Waste Project Engineer (RWPE)

The person in charge of the work on the construction projects is called the Project Engineer. A Supervisor or an Inspector may run the project on a daily basis depending on the District level of staffing for the project. The project engineer will randomly check in on the project and make any engineering decisions.

The Regulated Waste Project Engineer (RWPE) is in charge of all removal operations of regulated waste on the projects. The RWPE signs all manifests from the projects and ensures that all environmental documents from the project are transferred to the DEC for permanent storage. Each District will have at least two Engineers working at this function.

In some Districts, the District Environmental Coordinator (DEC) or District Hazardous Waste Coordinator (DHWC) may substitute for the RWPE if the RWPE is not available.

Administering the Contract

The RWPE has the responsibility to effectively administer all aspects of regulated waste on the construction project. They must familiarize themselves with the specifications, the contract, and Appendix 202 to perform their duties. The RWPE makes interpretations of the regulated waste contract documents and this manual to the project engineer, supervisors, or project inspectors. In addition, the RWPE insures that trained inspectors are inspecting the work.

The RWPE’s main contacts for environmental advice are the District Environmental Coordinators (DEC’s). The DEC’s coordinate environmental decision making with the District Hazardous Waste Coordinator, District Safety Representatives, Emergency Coordinators, and the Environmental Site Assessment Section in the Central Office of Environmental Services.

The following is a link to their names and numbers:

http://www.dot.state.oh.us/oes/

The list is at the bottom of the web page.

Reporting of Significant Changes

The Project Engineer is responsible for reporting any significant deviations in the contract documents to the District Construction Engineer and/or the County Manager. The Project Engineer has the authority to order the Contractor’s personnel and the environmental consultant to perform “as directed work” in all situations within the contract limits. This authority is tempered with a great deal of responsibility for their actions. If the Project Engineer orders work contrary to the recommendations of the RWPE, environmental specialist, or the environmental contractor, then the Project Engineer may become personally liable for their actions. The Project Engineer must be sure that their instructions are not contrary to any laws or regulations that govern the work before making any final decision.

Health and Safety Responsibilities

The RWPE, who has 24 hours Of HAZWOPER training, is responsible for the health and safety of the Department inspection forces.

Additional health and safety responsibilities are listed below:

- Ensures that inspections are being performed on the project with adequate personnel, equipment, and resources to complete the inspections safely.

- Ensures that telephone communications between the Department inspectors and emergency response personnel is maintained.

- Ensures that all inspectors are adequately trained and qualified to work at the site.

- Reviews the SSHSP, and ensures that the SSHSP is adapted by the Department to include ODOT inspection forces. For this review, the environmental consultant can be hired by third party billing through the Contractor or by the District Task Order Contract.

- Reviews the Contractor’s Site Specific Health and Safety Plan (SSHSP). Do not accept the SSHSP for liability reasons.

- Provides oversight of the Contractor’s operations as it pertains to the Contractor’s SSHSP.

- Reviews the SSHSP with the inspectors.

- Serves as the primary contact to review ODOT health and safety matters that may arise on the project.

- Informs the inspectors of revised or new safety protocols for the field operations.

- Informs the inspectors of revisions to the SSHSP.

- Reviews accident reports and the results of the inspections.

Project Inspector

The Project Inspector is responsible for the detailed inspection of the work and to follow the directions given by the RWPE, Project Engineer, and the SSHSP.

Contractor’s Responsibilities

The Contractor is responsible for prosecuting the work according to the plans and specifications. The 2002 CMS section 107.01 page 36, explicitly states that the Contractor shall comply with the construction safety rules and regulations. Employers are always responsible for the safety of their employees.

District Environmental Coordinator (DEC)

The DEC is responsible for giving technical advice to the RWPE, reviewing or hiring an environmental consultant to review the Health and Safety Plan for ODOT workers, and coordinating matters of safety and hazardous waste with the District Hazardous Waste Coordinator and District Safety Representative.

Construction Geotechnical Engineer (CGE) and Advisory Construction Engineers (ACE)

The CGE and ACEs in the Office of Construction Administration are responsible for giving technical contract administration advice to district construction personnel, updating this manual, and performing Quality Assurance Reviews and Training.

Training

General

Where the disposal of regulated wastes is necessary during construction, the District Construction staff must have knowledge beyond the plan note requirements in order to make appropriate and legally correct decisions when facing actual field mandated changes to the contract.

An understanding of the requirements of the Comprehensive Environmental Response, Compensation and Liability Act (CERCLA), the Resource Conservation and Recovery Act (RCRA), and Occupational Safety and Health Administration (OSHA) requirements is essential during the construction phase.

Training is available through the Office of Environmental Services in Central Office, Environmental Site Assessment Section (614-466-7942); Bureau of Workman Compensation, Division of Safety and Hygiene (800-644-6292); or through a variety of private training sources. The private training may be charged against the project on third party billing through the Contractor.

The following is a link to the Bureau of Workman Compensation, Division of Safety and Hygiene for some ‘free’ training courses:

http://www.ohiobwc.com/employer/programs/safety/SandHCourses.asp

Nothing in this manual requires ODOT project personnel to enter a hazardous waste site without the consent of the employee. All regulated waste removal work is performed by the Contractor, and no ODOT personnel should actively participate in this work.

The majority of the regulated waste removal operations on highway construction projects consist of the removal of solid waste or petroleum-contaminated soil. The minimum training requirements listed below should be observed for all regulated waste or underground storage tank removal projects.

Project Engineers

All Project Engineers are required to have the 8-hour ‘Construction Safety Awareness Class and 8 hour Construction HAZWOPER Awareness Class’. This training will be given every three years. This training will be enough to recognize hazards or conditions that require further investigation by other more specialized personnel.

Regulated Waste Project Engineer (RWPE)

The District will designate at least two Project Engineers with 24-hour Construction HAZWOPER training. These RWPE’s will deal with all regulated waste issues that arise on the projects. An 8-hour annual refresher course is required.

Project Inspector

All Project Inspectors are required to have the 8-hour Construction Safety and 8-hour HAZWOPER Awareness Training. Students completing this training will be able to recognize hazards or conditions that require specialized training.

Some consideration should be given to having a project inspector for inspecting underground storage tanks removals. Certified Underground Storage Tank Inspector training can be obtained from BUSTR. See 202 ‘Removal of Structures and Obstructions’ in this manual.

Specialized Inspection

Additional environmental consultant inspectors may be hired through the Districts or Central Office Environmental Site Assessment Task Order Contract to provide specialized inspection. The RWPE should contact the District Environmental Coordinator to obtain these services. The procedure is further explained in the section, ‘Obtaining Technical Advise or Inspection’ of this manual.

Medical Monitoring

Medical monitoring is required for employees working on hazardous waste projects who are:

- Exposed to contaminants above the permissible exposure limits (PEL) for more than 30 days per year.

- Wear a respirator for 30 days or more per year.

- Injured or become ill due to exposure to hazardous substances.

OSHA 29 CFR 1910.120 covers this requirement. The SSHSP, the District Safety Coordinator and the District Environmental Coordinator should be consulted to determine the need for medical monitoring of an employee. Medical monitoring is rarely needed due to the type of contaminates, solid wastes, or petroleum contaminated soil normally encountered on highway construction projects.

Changes to the Training Requirements

The SSHSP may alter the above requirements because of the particular contaminants on the project. Review Site Specific Health and Safety Plan Requirements and the project SSHSP.

Training and Medical Records

All training and medical records shall be kept according to sections 1105 and 1106 in the Hazardous Waste Program Manual (HWMPM).

Construction Safety Training

Confined Space, Trenching, Excavation Safety, and other construction related issues are covered by the 8-hour Construction Safety Awareness class. The 8-hour Construction Safety Awareness Training will be offered to all construction personnel every 3 years.

Additional training can be taken ‘free’ through the Bureau of Workman Compensation at 800-644-6292. Any personnel wanting extended training should take the following courses:

Trenching and Excavation Course SAF112

Confined Space Assessment and Work Course IHY214

These courses are offered all around the state at various times. Construction personnel can sign up for the courses at the following web site:

http://www.ohiobwc.com/employer/programs/safety/SandHCourses.asp

Site Specific Health and Safety Plan Requirements

The Contractor is required by OSHA and the contract documents to have a Site Specific Health and Safety Plan (SSHSP) when working within the exclusion or contamination zones of a construction project. Depending on the material contents of an underground storage tank, these exclusion zones may include the areas around the removal of underground storage tanks.

The Contractor is responsible for the health and safety of their personnel. The Contractor is required to have the SSHSP available at the project site for inspection. In no case will the Department accept or approve a Contractor’s SSHSP.

Under CMS 105.10, the Contractor must provide access to Department personnel to perform work inspections. The Contractor cannot restrict the inspection of the work when the inspection forces meet the minimum training requirements of the SSHSP.

The RWPE is responsible the health and safety of the inspection personnel. See “Health and Safety Responsibilities” in the Responsibility section of this manual. The RWPE may forward the Contractor’s SSHSP to the District Environmental Coordinator (DEC) for review. The DEC will note how the SSHSP affects the qualifications of the inspection forces. The RWPE, in consultation with the DEC, will determine whether department forces or consultant forces should inspect the work. If consultant inspectors are used, the consultant will be responsible for the health and safety of its employees.

Minimum Contents of the SSHSP

The SSHSP will contain the following information:

- Safety and Health Risk or Hazard Analysis

- Employee Training Assignments

- Personal Protective Equipments Requirements

- Medical Surveillance Requirements

- Frequency and Types of Air Monitoring

- Site Control Measures

- Decontamination Procedures

- An Emergency Response Plan

- Confine Space Entry Procedures (if necessary)

- Spill Containment Program

Further information about the SSHSP is detailed in the 24-hour training for the Regulated Waste Project Engineer.

Obeying the SSHSP Requirements

All construction personnel, including ODOT project personnel, will work under and obey the requirements of the SSHSP during the inspections. The project personnel should thoroughly review the SSHSP to become familiar with all the aspects of this document.

All ODOT personnel entering the contamination zone must wear the personal protective equipment (PPE) listed in the SSHSP. The training and equipment may be obtained by contacting the District Environmental Coordinator or Safety Coordinator. If the required equipment and training are not available to ODOT personnel, then this training may be paid for under third party billing through the Contractor.

Absence of a SSHSP

In the absence of a project SSHSP, the RWPE should contact the District Environmental Coordinator to determine the need for a SSHSP. There will be instances where an SSHSP is not required. Some solid waste or petroleum contaminated soil operations will generally not require a SSHSP.

Regulated Waste Designated for Removal in the Contract

General

Most hazardous waste sites are identified through environmental site assessment during the preliminary development process. These sites are avoided where possible. When these sites cannot be avoided, plans or notes will be placed in the contract to instruct the project personnel how to safely remove, cap, or remediate the contaminated material. Some typical plan notes are shown in the section “Typical Regulated Waste Plan Notes” of this manual

Projects involving the removal of regulated material may quickly become complicated from an administrative perspective. The District Planning and Production staffs should coordinate the plan notes and specialized requirements for each project with the District Construction staff to ensure that the construction inspection staff, including the Project Engineer, understands why the special notes are in the plans and what special administrative requirements are necessary. Time should be allotted to develop contracts for outside environmental inspectors if necessary and to determine if specific training is needed for ODOT inspectors.

Construction projects with complicated remediation work requiring a major amount of specific equipment, project staff, or time may be separated from the highway construction project to avoid overly complicating the project. Proper management and disposal or remediation of regulated waste and UST’s are essential to prevent future liability for the Department.

The Contractor is responsible for the proper removal of regulated waste. The project personnel are responsible to control the Contractor’s work according to the contract documents and all applicable laws and regulations.

Reference Material for Regulation Requirements

The Hazardous Waste Program Manual is an excellent reference to help the project personnel to familiarize themselves with the regulation requirements and the waste types, characteristics, and generation requirements. Also, consult the 24-hour Construction HAZWOPER training manual when dealing with these regulated wastes.

Plan Notes

The plan notes and/or environmental site assessment reports are available to the project construction personnel to help familiarize them with the type of contamination that will be encountered on the project. These reports should be available through the DEC, production, or the Office of Environmental Services in central office.

The specialized plan notes may require department or consultant environmental inspectors to field screen samples, and analyze soils excavated from areas of environmental concern. Contractors may be required to stockpile, containerize, or dispose of contaminated soils. The plan notes should allow the project to efficiently manage the disposal of the regulated wastes and/or UST’s encountered on the project.

The plan notes will outline who is responsible for what operation on the project. The RWPE should review the plan notes before the Contractor starts work. The following is a general outline of responsibilities.

Pre-Excavation Checks

The regulated wastes are usually located on the plans. Work can begin in these areas once the Project Engineer is satisfied that all of the following are complete:

- The SSHSP is present on the project.

- The Department has appropriate environmental inspectors.

- The Contractor has the appropriate work force to proceed with the work.

- The Contractor has set up the appropriate zoning as noted in the SSHSP.

The zoning includes but is not be limited to all of the following: Contamination Zone, Decontamination Zone, and the Safe Zone. These areas must be secured at all times, and are usually separated by a construction fence.

Excavation

Contamination areas are sometimes marked in zones designated as hazardous, solid, or other waste classifications. This gives the Project Engineer an insight into the general classification of the material in the contamination zones. This classification is generally not used for final disposal. The environmental inspector may field screen the regulated material prior to the stockpiling, but all materials are stockpiled and tested prior to the final disposal of the material.

In some cases, and with the permission of the regulatory agency and the District Environmental Coordinator (or as allowed by the plan notes), the material may be excavated and directly placed in trucks for disposal at the landfill. This may require additional testing of the excavation area. Substantial savings can be obtained when changing to this method on the project.

The plans generally call for the removal of enough material to build the highway. Unless otherwise called for in the plans, the Department does not clean up all the regulated material in the right of way. Contact the District Environmental Coordinator for cleanup instructions, unless a regulatory authority is overseeing this portion of the project.

Temporary Storage

The contract documents give general details about the temporary storage methods. The RWPE should review the Contractor’s proposed storage method and determine if the proposed method meets the intent of the plans. The project should review the storage locations daily to ensure the work is progressing satisfactorily while the work is in progress. A sample inspection form is in the Hazardous Waste Management Program Manual (HWMPM) in appendix k. All storage areas must be inspected weekly as per section 507 in the HWMPM when the work is not in progress.

Material Sampling

The contract or plan may require that the state’s environmental consultant or Contractor’s environmental specialist test the regulated waste after it is stockpiled. The testing amount and location will be detailed in the plan or determined by the environmental consultant.

ODOT employees should not be testing or sampling suspect hazardous waste material; this should be done by an environmental consultant. The Contractor is responsible for any other testing required by the landfill for disposal purposes. The Contractor is required to give all the testing results to the project.

The testing results shall be kept according to section 1104 in the HWMPM.

Evaluation

Once the material is tested and the results are known, the material may be classified into a regulatory category such as hazardous waste, solid wastes, petroleum contaminated waste, special, or non-regulated wastes. The material may be shipped to the appropriate landfill or onto other areas of the project if allowed. Petroleum contaminated soil is allowed under 203.02.K to be used as fill.

Manifesting

The manifest documents must be filled out and completed prior to the disposal of any hazardous waste material. Manifest documents are prepared by the Contractor and signed by the RWPE on behalf of the Department. The RWPE receives one copy of the manifest; the remaining copies go out with the trucker.

The Destinies of the various copies of the Manifest are as follows:

- Landfill: Original signed copy

- Project: 1st copy signed by Landfill

- Contractor: 2nd copy signed by Landfill

- Trucking Company: 3rd copy signed by Landfill

- Project: 4th copy kept by the Regulated Waste Project Engineer (RWPE) after they sign the manifest; it does not go with the load. The RWPE matches it with the Landfill signed 1st copy that is returned to the Project. The RWPE verifies that the two copies match.

The manifest form has these terms for the various parties:

|

Party |

Form Term |

|

Landfill |

DESTINATION |

|

ODOT Project |

GENERATOR |

|

Contractor |

OPERATOR |

|

Trucking Company |

TRANSPORTER |

There are four (4) carbon copies, so the RWPE needs to sign the forms with a lot of pressure.

One copy of the manifest comes back to the project when the regulated material is disposed at the regulating facility. The RWPE must ensure that all copies and material quantities are accounted for in a timely manner. See section 603 in the Hazardous Waste Management Program Manual for information about the action to be taken when a manifest does not come back to the project.

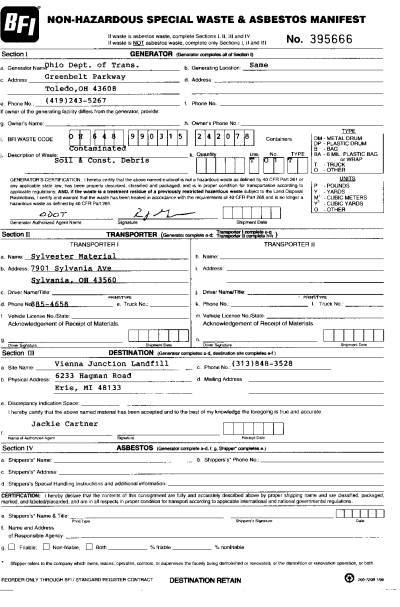

Examples of Manifests and a full description are shown in the Hazardous Waste Management Program Manual (HWMPM) in section 602. Most of the regulated material removed from construction projects will be either petroleum contaminated soils or a solid waste. Manifesting is required but there will not be an RCRA generator number on a solid waste manifest. An example of one is on Figure 202.APP.1.

Figure 202.APP.1 – Non-Hazardous Manifest

For more information regarding manifesting see sections 603 and appendix I of the HWMPM.

Pre-Transportation Requirements and Placarding

The Hazardous Waste Management Program Manual (HWMPM) is an excellent resource to determine the pre-transportation and placarding requirements. Sections 504, 605 and appendix P of the HWMPM provide a pre-transportation requirements and checklists. The Contractor is required to provide all of the material and manpower to provide for the proper identification, transportation, and disposal of the regulated waste. The RWPE must ensure that the packaging, labeling, and placarding are done according to the regulations.

Records of the Disposal

All documentation of the regulated waste operations should be recorded on CMS 1 or 2 and in the daily diaries. All records should be kept with the project files. The Regulated Waste Project Engineer needs to ensure that the records are kept in the District for future reference. The records need kept by the District Environmental Coordinator in the District.

If the regulated waste is classified as a hazardous waste, then all of the records keeping requirements listed in section 1101 in the HWMPM apply.

Weekly Project Inspections

When the project is conducting hazardous waste removal operations, then the RWPE will perform the weekly inspection requirements in 1107 in the HWMPM.

Regulated Wastes Found During Construction

General

Special procedures must be followed when the Contractor encounters potential regulated materials that were not anticipated by the plans. Section 203.04 of the 2002 CMS (page 102) describes the process for notifying Contractors and Department personnel of these special procedures.

Limit Access to the Suspect Area

Suspected regulated material must be left in place until identified by a qualified specialist. This may require the temporary discontinuance of work in the area of the suspect materials. The area in question should be secured to prevent access. This can be accomplished by cordoning off the area with rope or construction fence and posting a guard. On large projects, work may continue at locations sufficiently removed from the site in question.

Notification

The Project Engineer must be notified immediately, and should contact the RWPE. The Department will evaluate the level of risk to workers and to the public, and notify all responsible parties and regulatory agencies as required. The District will determine a course of action based on consultation with the appropriate environmental regulatory agencies and ODOT staff with specialized expertise in the hazardous waste field in the Office of Construction or the Office of Environmental Services. If it is determined that the area in question is or may be contaminated with environmentally regulated substances, the District will initiate the evaluation and remediation of the problem area as described below.

In the event of a life-threatening situation to human health outside the project, contact the Local Fire Department and the Local Police. Report the incident to the District Construction Engineer and the Highway Manager to determine if local involvement is required. When local involvement is required, notify the County Emergency Manager Director listed in the current version of the Incident Management System Responders Listing.

Releases

If a Hazardous chemical in excess of its reportable quantity is released to a water body or leaves the project site, all of the following must be notified:

- RWPE or DEC

- Local Fire Department

- The Ohio EPA at 800-282-9378

Reportable chemicals may be between 1 and 500 pounds depending on the chemical. The following web site refers to the Code of Regulation (CFR) that gives the reportable quantities limits. In addition, it gives explicit instructions about what action should be taken by the project personnel.

http://www.epa.state.oh.us/derr/ersis/er/er.html

At some point, the project should hire an environmental consultant to help with the required paperwork and technical advice.

Obtaining Technical Advise or Inspection

“It is imperative that “Action” be taken to mitigate the problem in a timely manner.”

If required, the District may seek the services of a qualified consultant specializing in regulated waste assessment and remediation, or third party billing through the Contractor, through the district or central Office task order contract.

The District or Central Office Environmental Site Assessment Task Order Contract can be used to provide specific environmental expertise for the consultation, evaluation and testing in these situations. The District's Planning and/or Environmental staff can aid in developing a request for a proposal for these services when the Task Order Contract is used. This can be provided at no cost to the project.

The specific consultation, testing, or inspectors hired through the Task Order Contract or other contracts should specify the type of environmental expertise needed. For example, a project involving underground storage tanks or petroleum contaminated soils requires knowledge of BUSTR rules and regulations, operation of organic vapor analyzers, and the ability to interpret laboratory data. A good minimum qualification for these projects would be a Certified Installer or Inspector under BUSTR’s rules. Projects involving hazardous solid wastes or other types of wastes require the appropriate type of expertise.

Development of the Remediation or Disposal Plan

The chosen environmental consultant must submit a sampling plan for the Department and OEPA (if applicable) for approval. Upon approval, the environmental consultant will perform the required sampling, testing, mitigation, and possible disposal.

If it is determined that no contamination exists, or that the problem has been resolved on the site, the Contractor will be directed to return to work.

If required, the environmental consultant or contractor will develop a removal or remediation plan jointly in consultation with ODOT, OEPA, or BUSTR as applicable.

Implementing the Plan

Once the contaminant is known and a plan to eliminate or mitigate the regulated material is determined, the Department may seek competitive bids from a qualified regulated waste disposal firm contractor to remove or mitigate the waste.

If the project cannot tolerate the time it would take to obtain competitive bids, the Department may request a waiver of competitive bidding from the Controlling Board and award it to an approved qualified environmental firm via third party billing through the Contractor.

Where treatment or disposal of the regulated material must be conducted concurrently with construction, it may be made a part of the construction contract.

Disposal and Remediation

A remediation contract will be initiated once all the approvals are obtained. The environmental consultant, contractor, or sub contractor will perform work according to this manual and the approved remediation plan.

The Department will keep complete records of all activities performed in the treatment, removal, transport, and disposal according to all applicable laws, rules, and regulations. These records are the same as detailed in the “Regulated Waste Designated for Removal in the Contract” section of this manual.

All of the disposal requirements of a regulated waste outlined in the Regulated Waste Designated for Removal in the Contract section still apply. A plan note similar to the ones in the Typical Regulated Waste Plan Notes section of this mannual , an excavation plan, and a SSHSP should be developed before the work begins.

Other Wastes and Environmental Considerations

General

It is important to be aware of other common construction materials that can cause environmental problems during or after construction. The most common materials are construction and demolition debris, landscape waste (buried or burned on site), and asbestos pipe. These materials were detailed in sections 105.16, 105.17 201 and 202. Other materials such as slag, scrap tires, railroad ties, and recycled materials are detailed in this section.

Slag Use on the Projects

Air-Cooled Blast Furnace Slag

Air-cooled blast furnace slag (slag made from making iron) has been known to produce a green, yellow, white, or black runoff (which can also smell like rotten eggs). The color is usually pH driven, and usually goes away in about six months but not always. The runoff may exceed the allowable pH limits under the Clean Water Act.

To minimize these problems all air-cooled blast furnace slag used for Items 203, 304, 306, 307, 503, 603, and SS-855 must pass the Sulfur Leachate Test detailed in Supplemental Specification 907 under the 1997 CMS and Supplement 1027 under the 2002 CMS.

The problems first showed up in Cleveland around 1992. The Ohio EPA wanted the slag industry to regulate themselves and change the ACBF slag chemistry by adding chemicals.

This did not work well, and in 1998 the Ohio EPA requested that the Department specify the bucket test. The bucket test was pre-2002 SS-907, and was successfully used in Chicago. The bucket test can detect if the sulfur content in the slag is too high. The bucket test was implemented by SS-907 in 1998.

Last year, the Ohio EPA found several more projects with environmental problems. One of the projects was ODOT’s. This Department project used RPCC (Recycled Portland Cement Pavement) and ACBF Slag. The RPCC was used in the undercut and the ACBF SLAG was used in the 304 material. The Department was cited for violating the Clean Water Act. This problem has cost approximately $120,000 to date, and has led the Department to hire an Environmental Consultant to remediate the problem.

The environmental problems on non-ODOT projects were clearly caused by the ACBF slag. On one of the projects, it cost millions of dollars to remove the ACBF slag because of the environmental problems. Another project is costing thousands of dollars a month to containerize and remove the runoff.

By reviewing the Ohio Administrative Code and environmental reports and performing lab tests, ODOT has developed the following solution in the 2002 version of SS-907 and S-1027:

- We have lengthened the time of the bucket test.

- We have incorporated some of the Ohio Administrative Code Water Quality requirements.

- We are testing for pH, conductivity and total dissolved solids.

These tests will minimize ODOT’s environmental liability. It is important that the Project personnel recognize these requirements and only use materials that meet these specifications.

Steel Slag

Steel slag can expand and produce tufa, which can block underdrains. All steel slag for Items 203, 304, 306, 307, 410, 411, 617 503, or 603 are restricted under Supplemental Specification 905 or in 703.14 and 703.15 in the 2002 CMS.

There are three types of slag detailed in these specifications, Open Hearth, Basic Oxygen Electric Arc slag. All slags are by products of making steel or iron. Open Hearth Slag (OH Slag) was produced pre-1970. Basic Oxygen Furnace slag (BOF slag) and Electric Arc (EA) are produced from a newer and faster process for making steel. The problems are worse for basic oxygen slag than for open hearth because the OH process is slower; the slower process burns more chemicals out of the OH slag. Very little Electric Arc slag was used for ODOT work but it has more detrimental effects than any of the steel slags.

Background on Open Hearth and Basic Oxygen Slag Restrictions

In the mid-1970's, the Department had severe expansion problems associated with bedding, backfill, and base material placed using OH and BOF steel slag. This problem caused the Department to spend hundreds of thousands of dollars due to premature failures.

As result of several years of research, the Department required a 6-month aging of all OH and BOF slags to solve the problem. It also eliminated the use of OH or BOF slags in confined areas such as pipe bedding and backfill, underdrains, and around structures.

In the late 1970's and early 1980's, OH and BOF slags were found clogging up underdrains systems. The use of OH and BOF slags was eliminated in Items 310 and 304.

In early 1990’s, the Department allowed the use of some OH slags if the field performance proved that the OH slag did not block underdrains.

In the 1997 specification book, the Department allowed OH slag in Items 203, 307, 306, 304, 410, 411, 603 and 617. BOF slag was allowed for Items 203, 410,411 and 617. The following is some of the reasoning behind the 1997 and 2002 specification changes.

- We consulted with Industry, Illinois, Indiana, Pennsylvania, and the Ohio Turnpike on this matter. ODOT reviewed past research and consulted with John Hurd, Stu Schwotzer and Phil Hall, who performed the majority of the research done in the past.

- The words “from sources on file at the Laboratory” have been misinterpreted in Items 304, 410, 411, and 617. The intent of this note was to verify tufa performance before the sources are used. This has been clarified.

- The expansion potential of OH and BOF slags are related to the concentrations of CaO and MgO. CaO leaches out during the aging process, while MgO may not. A test method is recommended to help determine the expansion risk. The recommended expansion test has a 20-year field performance related history.

- The risk is too great to allow BOF slag in base material. Therefore clear identification of OH slag is critical to base performance. A procedure to verify the material source as OH slag is detailed.

- Water and confining pressures cause additional expansion potential in OH and BOF slag. Therefore, all OH and BOF slag was eliminated in areas where the material is confined.

Summary

The problems found in the mid-1970's were primarily from projects built in the mid- 1960's. Tufa was not found blocking underdrains for about 10 years. Problems associated with ODOT projects built today may not arise for ten years or more.

The easy way out is to eliminate OH and BOF slag from use in all Department items of work. Certainly, the Department has documented enough bad performance related problems associated with OH and BOF slag to justify this elimination.

Most states do not allow steel slag for any base or confined areas period. Instead, we have implemented a method and procedure that allows the use of OH and BOF slag in certain applications to minimize the potential for premature failures.

The restrictions on the use of OH and BOF slag are intended to ensure we do not revisit those past expansion and tufa problems. Using materials that comply with the specifications minimizes environmental and engineering concerns.

Tufa Removal

Lime precipitant from slags used in the bases of older projects can create deposits that form on the side slopes. The deposited material will have a high pH, and may have to be taken to a solid waste landfill, if permitted. The material may be a hazardous waste if the pH is above 12.5.

When the project personnel notice these materials within the project limits, the deposits should be tested and removed as follows:

- This material should be tested under the task order contract.

- The contractor should perform the removal by force account.

Some projects may have special plan notes for the removal operations. The following plan note will be used to remove the tufa. If a large amount of tufa is on the project there may be other removal notes.

Environmental Work General Tufa Note (11/28/01)

A field review has determined that there are tufa deposits located between stations ______and stations _______ at the underdrain outlets. If these materials are encountered, manage this material according to the following.

Obtain all necessary testing for disposal, permits and approvals, and transportation of the material to a licensed (by the local health department) and permitted (by the state environmental protection agency) solid waste disposal facility.

Provide areas to stockpile the material. Stockpile the materials in a leakproof and covered container.

Ensure that all transport vehicles used for the movement of regulated material meets all applicable Local, State, and Federal requirements. Maintain records (such as manifests, landfill tickets, daily logs, etc.) to document the source, movement, and destination of each truckload of contaminated material. Submit one copy of each of these records to the Engineer.

Furnish all the labor, equipment, and materials necessary to excavate, store, test, transport, and dispose of the tufa material, including any required permits, approvals, or fees, within the aforementioned limits.

The Department will pay for this work according to 109.05 (2002 CMS) or 109.04 (1997 CMS).

Scrap Tires

Scrap Tires found on the project are transported under OAC 3745-27-56. The tires must be disposed of at a registered and permitted scrap tire facility as per OAC 3745-27-61 thru 65.

Use the following link to the OAC:

http://onlinedocs.andersonpublishing.com/oac/

Under these requirements, the transportation company and the disposal facility are regulated by the OEPA. Shipping papers are required to ship the tires to and from the facility. The District Environmental Coordinator or 24-hour trained Regulated Waste Project Engineer will sign the shipping papers for the Department. The records must be kept for three years.

Railroad Ties

The Ohio EPA encourages the use of railroad ties as landscape materials or other uses. When they must be disposed, they are disposed of in a construction and demolition debris site or a solid waste facility.

To date, creosote in railroad ties does not pose an environmental threat.

Recycled Materials

Supplemental Specification 871 allows the use of fly ash, bottom ash, foundry sand, glass, and tires in fills.

Supplemental Specification 871 can be found at the following web site:

http://www.dot.state.oh.us/construction/OCA/Specs/SS and PN 2002/default.htm

Recycled materials are defined in the 2002 CMS on page 100 in 203.02.N Recycled materials may be fly ash, bottom ash, foundry sand, glass or tires.

The link to 203.02.N is:

Under certain circumstances, petroleum contaminated soil in 203.02.K may also be used in fills. The environmental requirements are in 203.03.I on page 101 and 102.

The recycled materials are allowed in the interior sections of the fills. The approval on existing contracts will be on a case by case basis or if SS-871 is in the contract. Recycled materials are not allowed under the terms of the contract unless SS-871 is included.

The following Designer Note should be reviewed prior to considering using Supplemental Specification 871, Embankment Using Recycled Material:

The specification was written to allow the Districts to use recycled materials in embankment construction.

It was written to safely use these recycled products without jeopardizing the embankment or pavement integrity or long-term performance. The Department does not require the use of recycled materials because this specification does not eliminate all risk or liability to the Department. It only minimizes these risks.

The utilization of SS-871 is at the District’s discretion. Districts are advised to consider all the benefits and potential problems prior to allowing these materials.

Benefits

Recycled materials can be cheaper and provide engineering improvements to the embankment construction. For example, fly ash and tires can provide lighter weight materials.

By using these materials, the Department will save landfill space in the state. The Department may minimize the potential future legislation that would require the use of these materials. (Note: A few years ago, the state legislators required ODOT to allow petroleum-contaminated soil for embankment material, now under 203.02.K)

Potential Problems

Once these materials are placed on ODOT property, then the recycled materials will become the responsibility of the Department. ODOT will assume any future liability and costs for removal and proper disposal of material according to future EPA regulations. If this embankment is repaired in the future, the material may have to be disposed of in a landfill if required by Ohio EPA regulations.

A small percentage of tire fills have spontaneously caught fire. Fly ash is a silt and may be susceptible to frost heave and capillary action. Both problems are minimized by the engineering controls in the specification.

The District may pick and choose which recycled material to use or allow all of the recycled materials.

The District may allow different materials at certain locations along the project.

No change in the cross sections is needed to include SS-871 in the plans. This specification delineates the areas in which recycled materials are allowed.

The following plan note can be used to incorporate SS 871 in the contract.

Embankment Construction Using Recycled Materials

On this project, Supplemental Specification 871 Embankment Construction Using Recycled Materials applies. ____________________________(Put in the materials wanted or needed) may be substituted for Item 203 Embankment in the contract.

The Department will measure and pay for all work detailed in SS-871 according to the unit Bid Price for Item 203 Embankment.

Typical Regulated Waste Plan Notes

Typical Plan Note for: Non Regulated Materials, Petroleum Contaminated Soil and Underground Storage Tanks

ENVIRONMENTAL WORK

1. Introduction

Soil adjacent the New Hamlet Cleaners property (SE corner of SR 132 and SR 125) was tested and contained petroleum substances. These substances are present within the excavation limits for proposed underdrains, proposed 36" storm sewer, other utilities and/or roadway construction from Station 1+50 Lt. along SR 132 Station 370+70 Right along SR 125 (see Sheet 22/57). This material must be handled by the Contractor according the following notes. In addition, the Contractor shall remove four (4) underground storage tanks located within the proposed right-of-way limits in accordance with Item 202 of ODOT's Construction and Material Specification (CMS).

1.2 Site Specific Health and Safety Plan (SSHSP)

The Contractor shall certify in writing to the Engineer within two weeks after contract execution that the Contractor has prepared a SSHSP in accordance with OSHA 29 CFR Part 1910.120 for operations involving hazardous substances within the aforementioned limits. The Contractor shall make the SSHSP available at the project site. Copies of the environmental studies are available for examination in the Office of Contracts and the ODOT District 12, Office of Planning. This information may be used by the Contractor to develop the SSHSP.

1.3 Material Sampling

The Contractor shall provide the Engineer with five (5) days notice prior to beginning any excavation within the aforementioned limits to permit arranging for the necessary testing services. All material excavated by the Contractor between these limits during construction shall be subject to testing by an Inspector provided by the Engineer. The Inspector shall field-screen the excavated material for petroleum contamination using an organic vapor analyzer (OVA). At the discretion of the Inspector, the excavated material, which exhibits petroleum contamination, shall be stockpiled and segregated while samples of the material are analyzed by an independent analytical laboratory. Field-screening results and visual observation will be the basis for segregating excavated material. Soil samples shall to be tested for BTEX (Benzene, Toluene, Ethyl benzene, & Xylene) by Method 8020 and TPH by Method 8015. If the BTEX and/or TPH levels exceed levels set forth by the Ohio EPA Petroleum Contaminated Soil Policy, the material shall be treated as petroleum-contaminated soil. All field-screening instruments and initial sampling and analysis of soils will be provided by the Engineer at no cost to the Contractor.

1.4 Temporary Storage of Contaminated Soils

All excavated material, which is determined to be potentially contaminated with petroleum substances, shall be stockpiled in an area provided by the Contractor and approved by the Engineer. The Contractor shall stockpile the material in a leak proof, covered container provided by the Contractor. The material shall remain on-site until analytical results are received by the Engineer.

As an alternate, the Engineer may permit temporary storage of suspected contaminated soils on an impermeable membrane. The membrane should be surrounded by bales of straw to prevent the suspect soils from coming in contact with the original soils. An impermeable membrane shall be placed over the stockpile to prevent contact with precipitation and/or surface run-off.

1.5 Material Evaluation

The Inspector shall use the analytical results to determine the regulatory classification of the excavated materials. The excavated material may be classified in one or all of the following three categories:

1.5.1 ITEM SPECIAL - Work Involving Non-regulated Materials

The Inspector will determine if the excavated material is non-regulated. The work involved in this Item Special includes developing and complying with a SSHSP; handling, storage, and disposal/use of non-regulated materials. This material may then be used as backfill for other project purposes, if it meets the appropriate ODOT specifications.

1.5.2 ITEM SPECIAL - Work Involving Petroleum-Contaminated Soil

The Inspector will determine if the excavated material is petroleum-contaminated soil (PCS) based on the analytical test results. The Engineer will provide the Contractor with these test results. The Contractor shall be responsible for obtaining all necessary permits and approvals and to transport the material to a licensed (by the local health dept.) and permitted (by the Ohio Environmental Protection Agency) solid waste facility or a Petroleum Contaminated Soil Remediation Facility (PCSRF) for proper disposal or remediation. Prior to disposal, the Contractor shall contact the proposed facility to determine the additional testing required for disposal or remediation at that facility. The prices for these tests are to be included in the above pay item. The work involved in this pay item includes developing and complying with a SSHSP; handling, storage, testing (for disposal or remediation); and disposal or remediation of PCS. When directed by the proposed facility, the Contractor shall have an independent laboratory collect samples and test the excavated or stored materials for PCS disposal or remediation approval.

1.5.3 Work Involving Hazardous Waste

In the event the analytical test results for disposal purposes show the excavated material is a hazardous waste, disposal of this material shall to be paid for in accordance with section 109.04 of ODOT's CMS.

1.6 Backfill of Excavated Areas

All excavated areas shall be backfilled with suitable material in accordance with the project plans, applicable ODOT specifications, and/or as directed by the Engineer. All surplus or unsuitable excavated material that can be used in embankments shall be disposed of in accordance with Item 203.05 of ODOT's CMS.

1.7 General Notes

All transport vehicles used for the movement of regulated soils and/or water shall meet applicable Local, State, and Federal requirements. The Contractor shall maintain records (such as daily logs, landfill tickets, manifests, etc.) that document the source, movement, and destination of each truckload of contaminated soil. One copy of each of these records shall be submitted to the Engineer.

1.8 Basis of Payment

The Contractor shall furnish all the labor, equipment, and materials necessary to properly develop and comply with a SSHSP, excavate, store, test (for disposal), transport, and dispose of contaminated materials, removal of underground storage tanks, including any required approvals or fees within the limits identified above. Payment for this work shall be made at the contract prices bid per ton and per regulated underground storage tank. Work involving hazardous waste shall be paid for in accordance with section 109.04 of ODOT's CMS.

The following estimated quantities have been included in the General Summary for the work noted above:

Item Special - Work Involving Non-regulated Materials 160 Ton

Item Special - Work Involving Petroleum-Contaminated Soil 160 Ton

Item 202 - Regulated Underground Storage Tank Removed 4 each

Typical Plan Note for: Solid Waste, Water, and Regulated Water

ENVIRONMENTAL WORK (CUY - Aerospace Parkway, PID 16802)

1.1 Introduction

Environmental studies have shown that regulated material (foundry sand, etc.) is present within the following excavation limits:

All excavations within the aforementioned limits shall be paid for under the original plan bid items. The Contractor shall manage this material according to the following notes. The estimated quantity has been included in the General Summary for this work.

1.2 Site Specific Health and Safety Plan (SSHSP)

The Contractor shall determine if a SSHSP is required in accordance with 29 CFR Part 1910.120. Environmental studies information is available for examination at ODOT District 12, Planning Dept., 5500 Transportation Blvd., Garfield Heights, OH 44125.

All material excavated by the Contractor between these limits may be stockpiled in an area provided by the Contractor and approved by the Engineer. The Contractor shall stockpile the material in a leak proof, covered container provided by the Contractor.

The Engineer may permit temporary storage of the regulated soils on an impermeable membrane. The membrane shall be surrounded by bales of straw to prevent the suspected soils from coming in contact with the original soils. An impermeable membrane shall be placed over the stockpile to prevent contact with precipitation and/or surface run-off.

As an alternative, the Engineer may permit the Contractor to direct load the excavated regulated soils (located within the aforementioned limits) into trucks for subsequent disposal.

The Contractor shall provide the Engineer with five (5) days notice prior to any excavations within the aforementioned limits to permit arranging for the necessary testing services. All material excavated by the Contractor between these limits shall be subject to testing by an Inspector provided by the Engineer. The Inspector will conduct sampling and testing every 100 cubic meters of material excavated. Samples will be tested by the following USEPA test methods:

The Contractor shall properly transport and dispose of the excavated material that is considered surplus or unsuitable material in a licensed (by the local health department) and permitted (by the Ohio Environmental Protection Agency) solid waste facility. If required by the solid waste facility, the Contractor shall be responsible for conducting any additional sampling and analysis of the excavated material.

In the event the analytical test results for disposal indicate the excavated materials is a hazardous and/or TSCA waste, disposal shall be paid for in accordance with section 109.04 of ODOT’s CMS.

All excavated areas shall be backfilled with suitable material in accordance with the project plans or as directed by the Engineer.

If excavations within the aforementioned limits require dewatering for construction purposes, the Contractor shall dewater and subsequently dispose of waters by methods approved by the Engineer. All water containerized by the Contractor between these limits shall be subject to testing by an Inspector provided by the Engineer. Samples will be tested by the following USEPA test methods:

- The Contractor shall obtain all the necessary permits and/or authorizations needed to store, transport and dispose of the water in accordance with applicable local, state or federal regulations.

- The Engineer will classify the water removed from the excavation into one of the two following categories.

1.6.1 ITEM SPECIAL - Work Involving Water

The Engineer will determine if the water is non-regulated. The method for disposing of the non-regulated water shall be approved by the Engineer. Work involved with this Item Special includes the handling, storage, and disposal of the non-regulated water.

1.6.2 ITEM SPECIAL - Work Involving Regulated Water

The Engineer will determine if the water is regulated. The Contractor shall be responsible for disposal of the regulated water. The method for disposing of the regulated water shall be approved by the Engineer. The work involved in this Item Special includes the handling, storage, testing, and disposal of regulated water.

The Contractor shall furnish all the labor, equipment, and materials necessary to properly handle, store, test, transport, and dispose of regulated materials, including any required permits, approvals, or fees within the limits identified above. Payment for this work shall be made at the contract price bid per metric ton and/or cubic meter. The basis for conversion from cubic meter to metric ton is 2 metric ton/cubic meter. The following estimated quantities have been included in the General Summary for the work noted above:

690M65010 Item Special - Work Involving Solid Waste Mton

690M65020 Item Special - Work Involving Water Cubic Meter

690M65024 Item Special - Work Involving Regulated Water Cubic Meter

Typical Plan Note for: Ground Water Monitoring, Regulated Underground Storage Tanks and Scrap Tires

Environmental Work (HAM - 127 - 5.47, pid 9135)

Abandonment of Ground Water of Monitoring Wells

A total of three monitoring wells are present on the vacant lot located at 4135 Virginia Avenue (corner of Chase and Virginia). These wells shall be abandoned in accordance with the Ohio Department of Natural Resources’ (ODNR) Technical Guidelines For Sealing Unused Wells (Appendix 4, Sealing Monitoring Wells and Boreholes). Payment for this work shall be as per Item Special - Ground Water Monitoring Well Abandonment.

Removal of Underground Storage Tanks

The Contractor shall remove two (2) petroleum underground storage tanks in accordance with ODOT Construction and Material Specifications (CMS) Item 202. These tanks are located at 4135 Virginia Avenue (corner of Chase and Virginia).

Removal and Disposal of Scrap Tires

Scrap tires are located throughout the project area. The Contractor shall be responsible for removing, transporting, and disposing of these scrap tires as per this plan note.

The Contractor shall ensure that the tires are removed and transported in a manner that satisfies all the appropriate OEPA regulations. Specifically, the transportation of tires is governed by OAC 3745-27-56. The disposal of tires shall be at a registered and permitted scrap tire facility as per OAC 3745-27-61 thru 65. Payment for this work shall be as per Item 202 - Removal Miscellaneous: Scrap Tires.

Basis of Payment

The Contractor shall furnish all the labor, equipment, and materials necessary to perform the aforementioned work. The following estimated quantities have been included in the General Summary for the work noted above:

Item Special - Ground Water Monitoring Well Abandonment 3 each

Item 202 - Regulated Underground Storage Tank Removed 2 each

Item 202 - Removal Miscellaneous: Scrap Tires Lump Sum

Typical Plan Note for: Asbestos Abatement

Environmental Work (MIA - 48 - 8.534, PID 12860)

Asbestos Abatement

An asbestos survey of the bridge structure scheduled for demolition was completed 6/99 by a certified asbestos hazard evaluation specialist (CAHES). Approximately 440' of conduit, which contains asbestos materials, was identified on the bridge structure. A copy of the Ohio Environmental Protection Agency Notification of Demolition and Renovation Form with sections I-VII, XVII, XVIII completed is available at the District 7 ODOT office (Planning Department). The form must be submitted to OEPA-SWDO, DAPC (401 E. Fifth Street, Dayton, OH 45402) at least 10 days prior to demolition/renovation activities.

The Contractor shall take whatever precautions are possible to ensure that the asbestos containing material (ACM) does not become friable. To assure that the nonfriable asbestos material does not become friable or in the event that the nonfriable material becomes friable, the Contractor shall provide an individual trained in the provisions of NESHAP that will be on-site during the demolition and/or removal of the ACM conduit. All ACMs shall be properly containerized, transported, and disposed of in accordance with the state and federal regulations.

Basis of Payment

The Contractor shall furnish all the labor (including a CAHES), equipment, and materials necessary to complete, submit, and comply with the OEPA notification for and to remove, transport and dispose of asbestos containing materials in a licensed (by the local health department) and permitted (by the OEPA) solid waste facility. Payment for this work shall be made at the contract prices bid Lump Sum. The following quantity has been included in the General Summary for the work noted above:

690M98400 Item Special - Misc.: Asbestos Abatement Lump Sum

Typical Plan Note for: Removal and Disposal of Scrap Tires

Removal and Disposal of Scrap Tires (GRE - 42 - 14.25, pid 13134)

Scrap tires are located at approximately STA 23+660 to STA 23+720. The Contractor shall be responsible for removing, transporting, and disposing of these scrap tires as per this plan note.

The Contractor shall ensure that the tires are removed and transported in a manner that satisfies all the appropriate OEPA regulations. Specifically, the transportation of tires is governed by OAC 3745-27-56. The disposal of tires shall be at a registered and permitted scrap tire facility as per OAC 3745-27-61 thru 65.

Basis of Payment

The Contractor shall furnish all the labor, equipment and materials necessary to remove, transport and dispose of scrap ties in a registered and permitted scrap tire facility. Payment for this work shall be made at the contract price bid Lump Sum. The following estimated quantity has been included in the General Summary for the work noted above:

Item 202 - Removal Miscellaneous: Scrap Tires Lump Sum

Typical Plan Note for: Solid Waste and Regulated Water

ENVIRONMENTAL WORK (TRU - Belmont Avenue, PID 11910) 3/8/00

The Ohio Department of Health has issued a Contact Advisory for the sediments of the Mahoning River for polycyclic aromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), Mirex (a pesticide) and phthalate esters. Environmental studies conducted on sediments in the project area have shown that low levels of PAHs and metals are present within the stream bed. The Contractor shall manage all material required to be excavated from the river bed according to the following notes. Estimated quantities have been included in the General Summary for this work.

1.2 Site Specific Health and Safety Plan (SSHSP)

The Contractor shall certify in writing to the Engineer within two weeks after contract execution and prior to any excavation that would disturb the sediment in the river bottom that the Contractor has prepared a SSHSP in accordance with 29 CFR Part 1910.120 for operations involving hazardous substances within the aforementioned limits. The Contractor shall make the SSHSP available at the project site. Copies of the environmental studies are available for examination in the Office of Contract Sales (Room 118) and the District 4 ODOT office (Planning Dept.). This information may be used by the Contractor to develop the SSHSP.

The Engineer may permit temporary storage of the excavated material in a lined and covered roll-off box. As an alternative, the Engineer may permit the Contractor to direct load the excavated material into trucks.

The Contractor shall properly transport and dispose of the excavated material in a licensed (by the local health department) and permitted (by the Ohio Environmental Protection Agency) solid waste facility. If required by the solid waste facility, the Contractor shall be responsible for conducting sampling and analysis of the excavated material.

If the excavations in the aforementioned sediments require dewatering for construction purposes, the Contractor shall dewater, containerize, test, and subsequently dispose of waters by methods approved by the Engineer. The Contractor shall obtain all the necessary permits and/or authorizations needed to store, test, transport and dispose of the water in accordance with applicable local, state, or federal regulations.

All transport vehicles used for the movement of regulated sediments or water shall meet applicable Local, State, and Federal requirements. The Contractor shall maintain records (such as manifests, landfill tickets, daily logs, etc.) to document the source, movement, and destination of each truckload of contaminated sediments and/or water. One copy of each of these records shall be submitted to the Engineer.

1.6 Basis of Payment

The Contractor shall furnish all the labor, equipment, and materials necessary to properly develop and comply with a SSHSP, and handle, store, test, transport, and dispose of regulated materials, including any required permits, approvals, or fees within the limits identified above. Payment for this work shall be made at the contract price bid per metric ton and cubic meters.

The following estimated quantity has been included in the General Summary for the work noted above:

Item Special - Work Involving Solid Waste 50 MTON 690M65010

Item Special - Work Involving Regulated Water 5 CU M 690M65024

Documentation and Critical Inspections for 201, 202, and Appendix 202 Regulated Waste Requirements

This section recommends minimum documentation and critical inspection requirements for sections 201, 202, and Appendix 202 Regulated Waste Requirements. All of the following documentation requirements must be recorded in the project daily reports. References to the appropriate laws, specifications, and proposals and plan notes or details for all the inspector reports are required. Specifications or other requirements waived by the Project Engineer shall be noted on the daily diaries.

Regulated waste work may be inspected and documented by the District Environmental Coordinator (DEC), District Hazardous Waste Coordinator (DHWC), or Regulated Waste Project Engineer (RWPE). When the inspection is required by these individuals it will be denoted below.

In addition, clearances or reviews need to be performed by other offices or individuals in the Department will be noted. These are as follows, District Office of Production (DOP), Office of Geotechnical Engineering (OGE).

Item 201 Clearing and Grubbing.

- Proper Disposal. (See 105.16 and 105.17).

- Mark Right of Way or Cutting limits.

- Check the field conditions for accuracy.

- Count Trees or Stumps.

- If set up for individual payment.

- Check material removals according to 201.03.

- Check the required scalping locations.

Item 202 Removal of Structures and Obstructions.

1. Proper Disposal. (See 105.16 and 105.17).

- Check Items for removal prior to removal.

- Check removal item prior to filling or other work.

- Asbestos Pipe (DEC, DHWC or RWPE)

- Check pipe markings. (Project)

- Test the pipe for Asbestos.

- Who was notified?

- Check the qualifications of inspector and contractor.

- Record Remediation or demolition procedures.

- Record contacts with the regulating authorities.

- Manifest properly.

- Building Demolition. (DEC, DHWC or RWPE)

- Check and Complete the OEPA Notification of Demolition

- Check for Burning Permit.

- Manifest properly.

- Under Ground Storage Tanks. (DEC, DHWC or RWPE)

- Who regulates the tank removal?

- Check Contractor and Inspectors qualifications.

- Record conversations with BUSTR or the fire department.

- Record daily inspections.

- Obtain a copy of the permit.

- Record contacts with the division of air pollution control.

- Check bottom of USTs for contamination.

- Obtain Closure report.

- Perform risk assessment and remedial action, if needed

- Who was notified during a release?

- What and in what quantity was released?

- What action was taken?

- Was a clean up and final report required?

Appendix 202 Regulated Waste Requirements. (DEC, DHWC or RWPE)

Responsibility

- Report all significant changes. (Project)

- Health and safety requirements. (DEC, DHWC, or RWPE)

Training.

- Check Training for the project engineers, project inspectors, consultant inspectors.

- Check the medical monitoring needs.

- Check the training changes based on the health and safety plan.

- Keep training and medical records according to sections 1105 and 1106 in the HWMPM.

- Regulated Waste Project Engineer gives these records to the District Environmental Coordinator for storage.

- Check all personnel for construction safety training.

Site Specific Health and Safety Plan

- Obtain a copy of the health and safety plan.

- Review of the health and safety plan.

- Obtain a new health and safety plan, if required.

Regulated Waste Designated for Removal in the Contract

- Review the contract requirements in the plan, proposal, or specifications.

- Perform the pre-excavation checks.

- Record the excavation operations and quantities.

- Record the type of temporary storage.

- Record the material sampling evaluation.

- Hazardous Waste?

- Solid Waste?

- Special Waste?

- Non-Regulated?

- Proper manifesting.

- Record the pre-transportation requirements and placarding.

- Keep disposal records.

- Regulated Project Engineer ensures these records are given to the District Environmental Coordinator for storage.

- Keep running lists of the weekly inspections.

Regulated Wastes Found during Construction.

- Who and when was notified ?

- Who was hired to evaluate the wastes?

- What Tests were taken?

- What are the results?

- Perform the Work as in the previous section, “Regulated Waste Designated for Removal in the Contract”.

Other Wastes and Environmental Considerations

1. Slag (Project)

a. Check environmental requirements in the specifications.

b. Check the runoff from the materials after placement.

c. Check the underdrain outlets for Tufa.

d. Record the Tufa removal operations.

e. Same as hazardous or solid wastes. (DEC, DHWC, or RWPE)

- Scrap Tires (Project)

- Document the removal.

- Requirements the same as solid waste. (DEC, DHWC, or RWPE)

- DEC keeps the record for storage (forever) (DEC, DHWC, or RWPE)

- Rail Road Ties

- Same as construction and demolition debris.

- Recycling is encouraged.

- Recycled Materials (Project)

- Ensure of Stability (OGE)

- Check the Environmental Consultants Certification. (DEC, DHWC, or RWPE)

- Check the placement procedures in SS-871.