ITEM 421 MICROSURFACING

421.01

Description

421.02

Materials

421.03

Proportioning

421.04 Weather Limitations

421.05 Mixing

Equipment

421.06

Equipment Calibration

421.07

Spreading Equipment

421.08 Surface

Preparation

421.09 Test

Strip

421.10

Application

421.11

Acceptance

421.12 Method

of Measurement

421.13 Basis of

Payment

421.01 Description. This work consists of

constructing a cold laid polymer modified emulsified asphalt pavement course to

fill ruts or provide a leveling and/or surface course for existing

pavements. The paving mixture is composed of a polymer modified

emulsified asphalt binder, crushed aggregate, mineral filler, water, and other

additives.

421.02 Materials. Use a polymer modified emulsified

asphalt binder (Binder) consisting of the following materials milled together:

A. Natural SBR

latex modifier or synthetic SBR latex modifier

conforming to 702.14. Use only one type

of latex.

B. CSS-1h or CSS-1m (as required below) emulsified

asphalt conforming to 702.04, except the

cement-mixing test is waived. Use only emulsion certified according to

Supplement 1032.

Use

CSS-1mL (as defined below) if the project ADTT is

less than 2000, otherwise use CSS-1hL (as defined below). Do not use port

addition of the polymer to the emulsified asphalt. Provide to the Engineer

certified test data and a statement from the Binder manufacturer with each load

of Binder that the Binder is the same formulation as used in the mix design.

Ensure the Binder meets one of the following:

CSS-1hL:

Combine CSS-1h and SBR latex modified (L) to yield 3

percent SBR solids based on the weight of the asphalt

binder content of the Binder. Ensure that the SBR

latex modified residue conforms to the following requirements:

|

Test |

Description |

Specification |

|

Residue by Evaporation |

62 % |

|

|

Softening Point |

60 °C minimum |

|

|

Absolute Viscosity @ 60 °C |

8000 poise minimum |

CSS-1mL:

Combine CSS-1m and SBR latex modifier (L) to meet the

following properties.

|

Tests on emulsion, ASTM D 244, unless otherwise designated: |

|

|

Viscosity, Saybolt Furol, ASTM

D 88, at 25 °C (sec) |

20 to 100 |

|

Storage Stability Tests, 24-hr (% difference) |

1 maximum |

|

Particle Charge Tests |

Positive |

|

Sieve Tests (%) (Distilled Water) |

0.10 maximum |

|

Distillation to 260 °C, % by Weight, Residue, min[1] |

62 |

|

Tests on distillation residue: |

|

|

Penetration, 25 °C, 100 g, 5 sec (dmm)

ASTM D 5 |

70 to 90 |

|

Ductility, 4 °C, 5 cm/min, ASTM D 113 |

40 minimum |

|

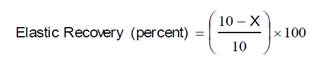

Elastic Recovery, 4 °C, 10 cm (%)[2] |

65 minimum |

|

Softening Point, Ring & Ball (°C) ASTM D 36 |

60 minimum |

|

[1] ASTM

D 244, with modifications to include a 400 °F ± 10 °F (204 °C ± 6

°C) maximum temperature to be held for 15 minutes. [2] Straight molds. Hold at test temperature

for 90 minutes. Place in ductilometer and elongate

10 cm at 5 cm/min. Hold for 5 minutes and cut. After 1 hour retract the

broken ends to touch and measure the elongation (X) in centimeters. Use the

following formula to calculate the elastic recovery:

|

|

Conform

to 703.01 and 703.05 for aggregate, except as follows:

|

Percent by weight of fractured pieces |

100 |

|

Sand Equivalence (ASTM D 2419) |

45 minimum |

Conform

to Gradation A for the aggregate for leveling and surface courses and to

Gradation B for the aggregate for rut fill courses according to the following:

|

Sieve Size |

|

Total Percent Passing |

|

|

|

A |

B |

|

|

3/8 inch |

(9.50 mm) |

100 |

100 |

|

No. 4 |

(4.75 mm) |

85 to 100 |

70 to 90 |

|

No. 8 |

(2.36 mm) |

50 to 80 |

45 to 70 |

|

No. 16 |

(1.18 mm) |

40 to 65 |

28 to 50 |

|

No. 30 |

(600 µm) |

25 to 45 |

19 to 34 |

|

No. 50 |

(300 µm) |

13 to 25 |

12 to 25 |

|

No. 100 |

(150 µm) |

– |

7 to 18 |

|

No. 200 |

(75 µm) |

5 to 15 |

5 to 18 |

Screen

the aggregate for oversize material prior to use. For mineral filler, use

Portland cement conforming to ASTM

C 150, Type I. Use water conforming to 499.02.

Use mix set additives as required.

421.03 Proportioning. Submit to the Laboratory a

sample of the Binder to be used and a complete mix design prepared by an

approved laboratory. Verify the compatibility of the aggregate, Binder, mineral

filler, and other additives. Make the mix design with the same materials

that will be used on the project.

Ensure

that the mix design:

A.

Has aggregate meeting the gradation specified.

B.

Has residual asphalt by dry weight of aggregate of 7.0 to 8.5 percent for

leveling and surface courses or 6.5 to 8.0 percent for rut fill courses.

C.

Has a mineral filler content of 0.25 to 3.5 percent by dry weight of aggregate.

D.

Meets the specified properties of the following International Slurry Seal

Association (ISSA) tests:

|

ISSA Test No. |

Description |

Specification |

|

TB-139

(1-90) |

Wet Cohesion |

|

|

30 minutes min. (set time) |

12 kg-cm min. |

|

|

60 minutes min. (traffic) |

20 kg-cm min or near spin |

|

|

TB-114

(1-90) |

Wet Stripping |

90 percent min. |

|

TB-100

(90) |

Wet Track Abrasion Loss 1-hour soak 6 day soak |

450 g/m² max. 650 g/m² max. |

|

TB-144

(2-89) |

Saturated Abrasion Compatibility |

3 g loss max. |

|

TB-113

(1-90) |

Mix Time @ 25 °C |

Controllable to 120 seconds |

|

Mix Time @ 40 °C |

Controllable to 35 seconds |

Check

the ISSA TB-139 (set time) and ISSA TB-113 (mix time) tests at the highest temperature

expected during construction. For the ISSA TB-113 test at 104 °F (40 °C), preheat all

ingredients and containers.

Ensure

that the final mix design states the following (all percentages are based on

the dry weight of the aggregate):

A.

Source of each individual material.

B.

Aggregate gradation.

C.

Percentage of aggregate.

D.

Sand equivalence of the aggregate.

E.

Percentage of mineral filler (minimum and maximum).

F.

Percentage of water (minimum and maximum).

G.

Percentage of mix set additives (if required).

H.

Percentage of Binder and type.

I.

Quantitative effects of moisture content on the unit weight of the aggregate.

421.04 Weather Limitations. Apply the

mixture only when it is not raining and the existing pavement surface

temperature is a minimum of 40 °F (5 °C) and there is no forecast of an

atmospheric temperature below 32 °F (0 °C) within 24 hours from the time the

mixture is applied. Between September 30 and May 1, do not apply the

mixture if the existing pavement surface temperature is less than 50 °F (10

°C).

421.05 Mixing Equipment. Produce

the mixture in a self-propelled, front feed, continuous loading mixing machine

equipped with a conveyer belt aggregate delivery system and an interconnected

positive displacement, water jacketed gear pump to accurately proportion

aggregate and asphalt emulsion. Locate the mineral filler feed so the

proper amount of mineral filler is dropped on the aggregate before discharge

into the pugmill. Provide a spray bar to

completely prewet the aggregate dropping down to the pugmill with additive and water before introduction of

asphalt emulsion. The twin-shaft, multi-blade pugmill

will be a continuous flow type and minimum of 49 inches (1.25 m) long.

Ensure that the blade size and side clearances meet the equipment

manufacturer’s recommendations. Introduce the emulsion within the first

one-third of the mixer length to ensure proper mixing of all materials before

exit from the pugmill.

Equip

the machine with opposite side driving stations to allow full control of the

machine from either side. Equip the mixer with a remote forward speed control

at the back mixing platform so the back operator can control forward speed and

level of mixture in the paving or rut box. Provide material control

devices that are readily accessible and positioned so the amount of each

material used can be determined at any time.

Equip

the mixing machine with a water pressure system and nozzle type spray bar to

provide a water spray ahead of and outside the spreader box when

required. Apply water at a rate that will dampen the surface, but will

not create free flowing water ahead of the spreader box.

The

Contractor may use truck-mounted machines with a conveyer belt aggregate

delivery system and without the front feed, continuous loading feature on

project segments of less than 15,500 square yards (13,000 m2) or on

spot repairs.

421.06 Equipment Calibration. Before

mix production, calibrate the mixing equipment in the presence of the

Engineer. Generate documentation for the Engineer, including individual

calibrations of each material at various settings. Perform a new

calibration if there is any change in the mix design. Supply all of the

equipment, materials, and scales necessary to perform the calibration.

Following calibration and adjustments for changes in the mix design do not make

any further calibration adjustments to the mixing equipment without the

Engineer’s approval.

421.07 Spreading Equipment. If a

leveling or surface course is specified, apply the mixture uniformly by means

of a conventional spreader box.

If

a rut fill course is specified, apply the mixture with a V-shaped rut filling

spreader box. Equip the rut filling spreader box with a steel strike-off.

Attach

either type of spreader box to the mixer and equip it with paddles mounted on

an adjustable shaft to continually agitate and distribute the materials

throughout the box. Ensure that the equipment provides sufficient

turbulence to prevent the mix from setting in the box or causing excessive side

build-up or lumps. To prevent loss of the mixture from the box, attach

flexible seals, front and rear, in contact with the road. Operate the

spreading equipment in such a manner as to prevent the loss of the mixture on superelevated curves.

For

surface courses, attach a secondary strike-off to the spreader.

The

Contractor may use burlap drags or other drags, if necessary, to obtain the

desired finish. Replace drags having excessive build-up.

421.08 Surface Preparation. Before

applying the mixture, thoroughly clean the surface.

Apply

a tack coat conforming to Item 407, consisting of one

part asphalt emulsion and three parts water. Apply the tack coat at a

rate of 0.06 to 0.12 gallon per square yard (0.25 to 0.45 L/m²).

Remove

raised pavement markers according to 621.08.

The Contractor may fill the depression caused by the removal of the casting

with material meeting this specification.

Remove any existing longitudinal pavement

markings 740.03 (polyester), 740.04 (thermoplastic) and 740.07(epoxy) using an abrasion method

conforming to 641.10. Protect

drainage structures, monument boxes, water valve, etc. during material

application.

421.09 Test Strip. Construct a test strip for the

Engineer to evaluate. Construct this test strip 1000 feet (300 m) long,

and include all of the application courses specified. Construct the test

strip at the same time of day or night the full production will be

applied. The Contractor may construct the test strip in 2 days or nights

if multiple course applications are specified.

The

Engineer will evaluate the completed test strip after 24 hours of traffic to

determine if the mix design is acceptable. The Contractor may begin full

production after the Engineer accepts the test strip.

If

the microsurfacing is not being applied between

September 30 and May 1, the Department will waive the test strip if the

Contractor has constructed a Department approved test strip this construction

season with the same materials and mix design.

421.10 Application. Apply the paving mixture

in a manner to fill cracks, shallow potholes, and minor surface irregularities

and achieve a uniform surface without causing skips, lumps, or tears.

Carry a sufficient amount of material at all times in all parts of the spreader

box to ensure complete coverage. Avoid overloading of the spreader

box. Do not allow lumping, balling, or unmixed aggregate in the spreader

box.

If

a rut fill course is specified, apply enough material to fill the wheel paths

without excess crowning (overfilling). An excess crown is defined as 1/8

inch (3 mm) after 24 hours of traffic compaction. Apply rut fill courses

in widths from 5 to 6 feet (1.5 to 1.8 m) for each wheel path. Provide a

smooth, neat seam where two rut fill passes meet. Take care to restore

the designed profile of the pavement cross-section. Feather the edges of

the rut fill course to minimize the use of excess material.

If

a leveling course is specified, apply the paving mixture at 14 ± 2 pounds per

square yard (7.6 ±1.1 kg/m²).

If

a surface course is specified and it is placed on another microsurfacing

course, apply the paving mixture at 16 ±1 pounds per square yard (8.7 ±0.6

kg/m²). If a surface course is specified and it is not placed on another microsurfacing course, apply the paving mixture at a

minimum of 18 pounds per square yard (9.8 kg/m²).

For

leveling and surface courses, provide a smooth, neat seam of 1 to 3 inches (25

to 75 mm) where two passes meet. Immediately remove excess material from

the ends of each run.

Construct

surface courses wide enough to cover the outside edges of rut fill and leveling

courses. Maintain straight edge lines along curbs and shoulders. Do

not allow runoff of these areas. Ensure that lines at intersections are

straight.

Use

squeegees and lutes to spread the mixture in areas inaccessible to the spreader

box and areas requiring hand spreading. The Contractor may adjust the mix

set additive to provide a slower setting time if hand spreading is

needed. Do not adjust the water content to adjust the setting time.

If hand spreading, pour the mixture in a small windrow along one edge of the

surface to be covered and spread it uniformly by a hand squeegee or lute.

Ensure

that the microsurfacing cures at a rate that will

permit traffic on the pavement within 1 hour after application without damaging

the pavement surface. However, should the contractor have concerns about

adequate cure, work out an arrangement agreeable to the project before

releasing traffic on the pavement.

If

there is an excessive streaking problem created by high amounts of oversize

material in the mix, stop applying the mixture and take steps to correct the

streaking problem. Do not resume work until the Engineer is satisfied the

problem has been corrected.

If

a section of pavement is not going to be exposed to traffic within 48 hours,

compact it with a pneumatic tire roller after curing. Conform the

pneumatic tire roller to 401.13, and inflate the

tire pressure to 40 to 60 pounds per square inch (275 to 400 kPa).

421.11 Acceptance. Maintain continuous control of

the binder to dry aggregate proportioning to conform to the approved mix design

within a tolerance of ±2 gallons per ton (±8.5 L/metric ton). Control the

spread rate to not less than the specified quantity of aggregate per square

yard (square meter) on a dry weight basis.

The

Engineer will base acceptance of the Binder to dry aggregate proportion and

spread rate on the Engineer’s summary of quantities used each day. The

Engineer will approve and accept a day’s application of microsurfacing

provided:

A.

The Engineer’s summary indicates conformance with the above control

requirements for proportioning and spread rate and

B.

The pavement is free from excessive scratch marks, tears, rippling and other

surface irregularities, longitudinal joints and lane edges coincide with any

lane lines and edge lines and transverse joints are uniform, neat and provide a

smooth transition.

The

spread rate requirement does not apply to rut fill courses if the Contractor

filled the wheel paths according to this specification.

421.12 Method of Measurement. The

Department will measure Microsurfacing, Surface

Course and Microsurfacing, Leveling Course by the

number of square yards (square meters), complete and accepted in place.

The Department will base the width of the pavement course on the width shown on

the plans, specified in this specification, or directed by the Engineer.

The Department will measure the length along the centerline of each roadway or

ramp.

The

Department will measure the number of raised pavement markers removed.

The

Department will measure Microsurfacing, Rut Fill

Course by the number of tons (metric tons) of dry aggregate used, complete and

accepted in place. The Department will base the weight of the dry

aggregate used on the ticket net weight of individual loads from an approved

scale.

421.13 Basis of Payment. The cost

of tack coat is incidental to Microsurfacing.

The

cost of any removal of any existing longitudinal pavement markings according to

421.08 is incidental to Microsurfacing.

The

Department will pay for removal of existing raised pavement markers according

to Item 621 Raised Pavement Markers Removed.

The

Department will pay for the construction of accepted test strips at the

individual bid prices for the courses constructed.

The

Department will pay for accepted quantities at the contract prices as follows:

Item

Unit

Description

421

Square

Yard

Microsurfacing, Surface Course

(Square Meter)

421

Square

Yard

Microsurfacing, Leveling Course

(Square Meter)

421

Ton

Microsurfacing, Rut Fill Course

(Metric Ton)