632

TRAFFIC SIGNALS and 633 SIGNAL CONTROLLERS

632-3 Electrical Appurtenances

632-4 Power Service for Traffic Signals

632-5 Pole and Support Inspection - General

632-7 Sag and Vertical Clearance

632-8 Signal Span Messenger Wire and Appurtenances

632-9 Method of Measurement for Cable and Wire

632-10 Signal Equipment and Wiring

632-11 Signal Performance Tests and System Checks

632-1 General - Signals

This information is

intended to serve as a guide for construction personnel where the contractor

furnishes and installs traffic control devices and appurtenances. However, it

may also be useful for maintenance personnel performing the same functions.

Inspection procedures for the various type traffic control devices are

outlined, mainly in the form of check lists to assist project personnel in

performing their duties. This information points out the various important

features of each device and references the applicable specification or standard

drawing. Illustrations are used for easy recognition of the device or feature

being discussed.

632-2 Foundations

See Section 630-3 for additional information

relative to concerns in the installation of foundations for poles and

controller cabinets.

632-3 Electrical Appurtenances

632-3.1 General

This section will be

used to provide additional information about various electrical appurtenances

involved in the traffic signal installations, such as pull boxes, conduit and

ground rods.

632-3.2 Pull Boxes

Pull boxes shall be

of the specified sizes (see SCD HL-30.11

and the plans), typically 18 inches (460 millimeters) or 24 inches (610

millimeters), and the specified material.

The word on the cover

should be “TRAFFIC” when the pull box is part of a traffic signal system unless

the plans require the word “ELECTRIC” or other marking. The word shall be

formed on the surface or displayed on an attached metal plate in accordance

with CMS 725.09.

The location of pull

boxes shall be as shown on the plans. However, pull boxes in low drainage areas

may be adjusted to eliminate drainage problems, or feasible methods of positive

drainage may be used in accordance with CMS Item 603 and details on

SCD HL-30.11,

with the approval of the project engineer.

Pull boxes located

in sidewalks, traffic islands and curbed areas close to the roadway, where wide

turning vehicles could drive over them, may be adjusted to eliminate the

problem, or a concrete pull box with a heavy duty lid may be used with the

approval of the project engineer.

632-3.3 Trench

Trenching shall be

in accordance with CMS 625.11 and

as shown in TEM Figure 498-7.

Any change in dimensions will require approval by the project engineer.

Trenching may be in

earth or in paved areas, according to plan details. Trenching and subsequent

restoration of surfaces in paved areas shall be in accordance with SCD HL-30.22.

Trenching work in paved

areas shall be divided into two pavement depths for payment; less than 6 inches

(150 millimeters) and 6 inches (150 millimeters) or greater, as described in

CMS 625.21.

The trench in paved

areas may be 4 inches (100 millimeters) wide when cut by a Vermeer type

trencher. In this case, the trench shall be backfilled with concrete full

depth, except that the bottom 4 inches (100 millimeters) above the conduit may

be CMS 625.11

tamped backfill.

632-3.4 Conduit

Metal conduit shall

comply with CMS 725.04,

with sizes according to the plans. It shall be made from domestically produced

steel, and the domestic steel content of the conduit shall be certified by the

manufacturer or supplier before it is approved for installation.

The routing of loop

detector wire in conduit through curb or under shoulder shall be as shown on

SCD TC-82.10.

Conduit containing

cable and/or wire shall have the terminal at the high end completely sealed in

an approved manner, with removable sealing compound or a molded plastic or

rubber device compatible with the conduit, cable jacket and wire insulation,

according to CMS 625.12(A).

After placement, a

conduit which will not have cable or wire pulled into it during construction

shall have a pull wire installed in it, and the terminal at the high end shall

be sealed with removable sealing compound, a molded plastic or a rubber device,

according to CMS 625.12(A).

Difficult pulling

and possible jacket skinning may occur when an attempt is made to install too

many cables or wires within a given conduit. The reason could be design error

in new systems or attempts to insert an excess number or size of cable or wire

in existing conduit.

Good electrical practice requires that the combined cross section of all cables and wire within a conduit should be less than (or equal to) 40 percent of the conduit inside area:

a1 + a2 + a3 + etc. < 0.40Ci

a = cable or wire across section area, sq. in. (mm2)

Ci = conduit inside area, sq. in. (mm2)

A calculation can be

made using the above formula. The cross section area of conduit, cable and wire

is shown in TEM Table 497-1.

632-3.5 Ground Rod

A ground rod shall

be driven below groundline near the foundation of every strain pole and

overhead sign or signal support whether there is power in the vicinity or not,

as shown on SCDs TC-21.20,

TC-32.10

and TC-32.11.

Ground rods shall

comply with CMS 725.16

and be installed in accordance with CMS 625.09. A ground wire of insulated 600-volt No. 4

AWG 7-strand soft drawn copper shall be attached by an exothermic weld. The

typical exothermic weld procedure is described in Section 632-3.6.

Insulating varnish shall

be applied to the weld and any exposed conductor.

632-3.6 Exothermic Weld

The following

procedure is typical and may be used unless the manufacturer’s instructions

differ.

- The end of the ground wire shall be in an

un-flattened, unbent, clean and dry condition to assure a good weld.

- Bent and out-of-round conductor wire

will hold the mold open causing weld material leakage. A cable cutter

should be used to make un-deformed ends. If a hacksaw is used, the

insulation should first be peeled, as the saw tends to coat the cable

with plastic material, which must be cleaned off.

- Corroded cable shall be cleaned. Oily

or greasy cable should be cleaned with a solvent that dries rapidly and

leaves no residue. Very greasy cable can be “cooked out” by dipping into

molten solder.

- Wet cable can cause the blowing of

molten metal out of the mold, and the cable should be dried by a hand

torch or a quick drying solvent such as alcohol.

- Ground rod ends which have been

mutilated in driving can hold the mold open and should be cut off. Rod

ends shall be clean and dry.

- The weld mold shall be clean before use.

Damp or wet molds can cause porous welds and should be dried by heating.

- The cable shall be inserted into the

side of the mold so the cable is 1/8 inch (3 millimeters) back from the

center of the tap hole. The mold shall be placed on the ground rod so the

cable sits on top of the rod (see TEM Figure 498-8). A clamp

or locking pliers should be used on the rod to keep the mold from sliding

down during the welding process, and the conductor should be marked at the

mold surface so it can be verified that the conductor has not shifted

before the weld is made.

- The steel disk shall be inserted into

the crucible and the cartridge contents poured on top, being careful that

the disk is not upset. The cartridge should be tapped when pouring, to

make sure the starting powder comes out and spreads evenly over the

welding powder. A small amount of starting powder should be placed on the

top edge of the mold under the cover opening for easy ignition.

- The proper cartridge size is marked on

the mold tag and is the approximate weight of the powder in grams.

- If the proper cartridge size is not available,

two or more small cartridges or part of a larger cartridge can be used.

- The mold cover will be closed and the

starting powder ignited with a flint gun. If it is necessary to hold down

the cover during the flash of igniting powder, a long tool should be used

and the hand should be kept away.

632-4 Power Service for Traffic Signals

632-4.1 General

Power service for

traffic signals shall comply with SCD TC-83.10

and the plans. It shall consist of the equipment needed to provide a

pole-attached wiring raceway and disconnect switch, for use with separately

furnished power cable routed from the service point to the controller cabinet.

As shown in TEM Figure 498-9,

unless otherwise specified, the equipment includes a weatherhead, a conduit

riser with necessary fittings and attachment clamps when required, and a

disconnect switch with enclosure (CMS 632.24).

A thorough review of

the plans should be made to determine that the specific requirements of the maintaining

agency for power service have been satisfied.

A ground wire shall

be used as shown on SCD TC-83.10,

leading to a ground rod installed in accordance with Section 632-3.5.

The LB type fitting

under the controller cabinet (SCD TC-83.10)

may have to be installed before erecting the pole because of interference with

the foundation.

632-4.2 Electric Meter Base

When required, an

electric meter base shall be furnished by the applicable utility and installed

by the contractor as part of the power service work.

632-4.3 Conduit Riser and Weatherhead

Power cable is the

only type cable or wire permitted through the power service conduit riser.

The conduit riser shall terminate at the meter base,

if used; otherwise, termination shall be at the switch enclosure. From there

conduit connection to the controller cabinet is as shown on the plans. Conduit

connection could be:

- immediately to the controller cabinet on

the same pole;

- downward by underground conduit and

possibly a pull box to a nearby foundation-based controller cabinet;

- upward by another riser on the pole to

spanwire and a remote cabinet location.

The conduit riser

shall comply with CMS 725.04

and the plans, and the weatherhead shall be threaded aluminum or galvanized

ferrous metal (CMS 732.16).

Risers on painted poles shall be painted to match the poles.

632-4.4 Disconnect Switch

The disconnect

switch shall be a UL listed single-throw safety switch or circuit breaker,

meeting the voltage and capacity requirements of the specifications. The

amperage rating of the fuse or circuit breaker shall be 5 to 10 amperes greater

than the peak load rating of the equipment service. The enclosure shall be a UL

listed water tight lockable stainless steel NEMA Type 4, supplied with UL

listed conduit hubs, and the enclosure shall contain a solid neutral bar

normally grounded to the enclosure (CMS 732.21).

632-5 Pole and Support Inspection - General

See Sections 630-4.2, 4.3

and 4.4 for information about pole

and support inspection.

632-6 Traffic Signal Supports

632-6.1 General

This section will be

used to provide additional information about traffic signal supports. Various

types of overhead signal supports are also depicted in TEM Table 497-4.

632-6.2 Strain Pole Type Support

Strain poles shall

comply with the manufacturer’s shop drawings, SCD TC-81.10

and the plans.

They shall be

galvanized unless paint is specified in the plans, and the general features

should be inspected in accordance with Section 630-4.2.

When strain poles of

the embedded type are specified, they shall include an extension for embedment

below groundline and a welded-on ground sleeve. The pole extension shall be

sufficient to reach within 3 inches (76 millimeters) of the foundation depth as

specified in the table in SCD TC-21.20,

or the extension may be a minimum of 6 feet (1.8 meters) if a reinforcement

cage is provided as also shown on the SCD. The cage shall overlap at least 24

inches (610 millimeters) of the pole extension and reach to within 3 to 4

inches (76 to 102 millimeters) of the foundation’s specified depth. A special

foundation design is required when soil with a load bearing capacity of less

than 2,000 pounds per square foot (9700 kilograms per square meter) is

encountered. Embedded poles normally do not include a handhole or blind half

couplings for internal wiring.

When shown on the

manufacturer’s shop drawings, and as permitted by CMS 732.11,

strain poles may be tapered tubes with a cross section which is circular or a regular

polygon of six or more sides, or may be a type consisting of straight sections

with a tapered effect accomplished by the use of reducers.

Strain poles used to

support traffic signals or signs (SCD TC-17.10)

shall be furnished with one or more span wire clamps with shackles for

attachment of messenger wire (see SCD TC-84.20).

The messenger wire

may be attached by wrapping twice around the pole and securing with a

three-bolt clamp, as shown in SCD TC-84.20,

when used on round, tapered steel strain poles.

Erection of these

poles shall be in accordance with the general procedure given in Section 630- 4.6, except as noted in this

section.

For the initial rake

of strain poles of the anchor base type, leveling nuts shall be adjusted to

provide a rake of one-eighth to one-half inch per foot (11 to 42 millimeters

per meter) of pole in the direction opposite to the contemplated span wires and

are to be made snug tight. Further adjustment may be necessary to assure that

the strain poles are essentially vertical after the application of span wire

load.

For the initial rake

of strain poles of the embedded type, poles shall be embedded in concrete to

provide a rake of one-eighth to one-half inch per foot (11 to 42 millimeters

per meter) of pole in the direction opposite to the contemplated span wire and

braced. The age of the concrete before it is considered cured, before the

bracing may be removed, and before the permitted application of span wire load,

shall be in accordance with Section 630-3.4.

632-6.3 Single Arm Support

Single arm supports

shall comply with the manufacturer’s shop drawings, SCD TC-81.20

and the plans. General features of the support shall be inspected in accordance

with Section 630-4.2, and except as

noted in this section, erection of the support shall be in accordance with the

general procedure given in Section 630-4.6.

Welds shall be

inspected according to Section 630-4.3

and the galvanizing inspected according to Section 630-4.4.

For arms of two

telescoping pieces, a 15 inch (380 millimeters) overlap is required. The

overlapped arms shall be secured with a stainless or galvanized steel

through-bolt with hex head or nut(s). Arm caps shall cover at least 50 percent

of the end area (CMS 732.11).

An arm clamp with

clevis shall be furnished at each signal position, as well as a hole with a

rubber grommet for the outlet of signal cable.

The installation of

small signs and their attachment to the arms should be checked. Any possible

interference between swinging signals and signs should also be checked.

Blind half couplings

shall be located on the pole of the support for mounting pedestrian signal

heads or controller cabinets when required by the plans.

Signal heads shall

be installed so that their bottom surface is 16 to 18 feet (4.9 to 5.5 meters)

above the roadway. The signals shall be installed at essentially the same

elevation. Drop pipes should be used only when necessary to maintain the

clearance between 16 to 18 feet (4.9 to 5.5 meters). If the clearance without a

drop pipe will be slightly over 18 feet (5.5 meters), it is permissible to omit

the drop pipe, with the maintaining agency’s approval.

Initial rake shall

be adjusted so that under the load of signals, the pole will assume an essentially

vertical position and the arm rise be within the limits specified on SCD TC-81.20,

i.e., 3 inches (76 millimeters) minimum and 12 inches (300 millimeters)

maximum.

632-7 Sag and Vertical Clearance

TEM Figure 498-13 illustrates sag guidelines and vertical

clearance standards for traffic signals.

632-8 Signal Span Messenger Wire and Appurtenances

632-8.1 General

This section will be

used to provide additional information about signal span messenger wire and

appurtenances.

632-8.2 Signal Messenger Wire and Cable

Messenger wire and

accessories shall comply with SCD TC-84.20

and CMS 732.18.

Messenger wire diameter shall be in accordance with the plans.

The height at which

the messenger wire is to be attached to the pole will, in some instances, be

shown on the plans. In cases where this is not shown, the contractor is

responsible for determining the proper attachment height. This determination

shall consider the relative elevation of pavement to pole foundation top, the

desired clearance between pavement and the bottom of each signal, i.e., 16 to

18 feet (4.9 to 5.5 meters), the sag in the messenger wire (3 to 5 percent),

and the height of each signal.

Alternate methods of

attaching messenger wire to strain poles may be used, as follows:

- Span wire clamp with clevis, anchor

shackle and thimbles on the messenger wire, or

- Messenger wire wrapped twice around the

strain pole and secured with a three-bolt clamp of the proper size, when

used on round, tapered strain poles.

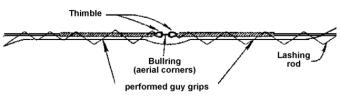

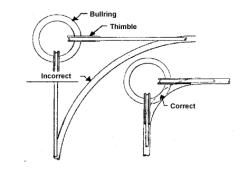

If the messenger wire attachment to strain poles makes use of the alternative with pole clamps and anchor shackles, the wire is to be hooked through the shackle using a thimble and secured with a three-bolt clamp. A preformed guy grip shall not be used for messenger wire attachment at the pole. Guy grips of the proper size may be used at bull rings (aerial corners).

Thimbles with a correct

groove size for the messenger wire (or the wire and eye of guy grips) are to be

used at anchor shackles and bull rings. When three-bolt clamps are used, the

wire tail is to be served as shown in Section 632-8.3. See Section

632-8.4 for the installation procedure for preformed guy grips.

Thimbles with a

correct groove size for the messenger wire or the preformed guy grip shall be

used to connect to anchor-type shackles or to bull rings at span wire aerial

corners.

Messenger wire sag

shall comply with CMS 632.22

and Section 632-7.

The signal cable

shall be attached to the messenger wire by lengths of preformed lashing rod.

The lashing rod

shall be the proper internal diameter to snugly hold the cable, but not cut

into its jacket. See Section 632-8.6 for further information.

A drip loop shall be

formed in the signal cable at each weatherhead, and should extend at least 6

inches (150 millimeters) below the weatherhead (see TEM Figure 498-14).

Cables or groups of

cables up to a maximum of four, hanging within pole interiors, shall have their

strain relieved by cable support assemblies as described in Section 632-8.7,

TEM Figure 498-14 and

SCD TC-84.20.

632-8.3 Messenger Wire Served Ends

Messenger wire may

be attached to various accessories by looping the wire to make an eye.

The wire end shall

be secured by a three-bolt clamp, and the cut wire end or tail shall be

“served” with construction wire or clamped with a sleeve device as shown on SCD

TC-84.20.

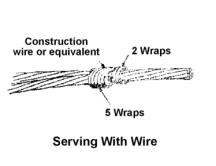

The following illustrations show both serving methods for the wire tail:

632-8.4 Preformed Guy Grips

Preformed guy grips

are made of helically shaped high-strength steel wire. They are available in

sizes fitting the outside diameters of messenger wire and form an eye

permitting attachment to various accessories.

As shown in SCD TC-84.20,

they should be used at bull rings of span wire aerial corners (see the

following illustration). Thimbles are used in the eye of grips in accordance

with standard details in the SCD.

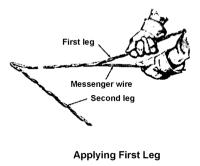

Grips are installed

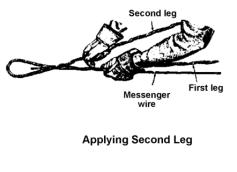

on an end of the messenger wire by wrapping a first leg of the grip to the

messenger wire. In most cases, the accessory to which the grip is to be

attached must be inserted in the eye of the grip with a thimble before the

second leg of the grip is wrapped. The second leg is then applied to the

combined first leg and messenger wire. The following illustrations show the

wrapping sequence:

Guy grips shall not

be used on messenger wire used for span wire sign supports. In this

application, wind load on the signs can cause failure of the grips (see SCD TC-17.10).

Guy grips shall not be used for attachment to signal strain poles (SCD TC-84.20(5)).

632-8.5 Cable and Wire

In certain instances,

the plans will assign a color code usage for each cable, or a typical usage by

color code. All connections should be made observing these assignments, and any

deviations, if determined necessary, should be recorded. When a color code

usage is not provided, good electrical wiring practice would still dictate that

color code wiring on the project be consistent.

Typically, white is

reserved for the neutral or common leg of a circuit. The following provides

additional information about various types of cable and wire contained in CMS

Table 732.19-1:

- Signal cable is used as the electrical

connection between signal heads and the controller cabinet at an

intersection. The cable may be either IMSA 19-1, which has a jacket of

polyvinyl chloride, IMSA 20-1, which has a polyethylene jacket, or IPCEA

S-61-402. The number of conductors and wire gage shall be as specified on

the plans. Conductors shall be of copper and stranded, and conductor

insulation shall be color coded. Splices are not permitted in signal cable

(CMS 632.23),

and the cable should be scanned to be sure that there are none.

As temperatures decrease, signal cable gets stiffer and harder,

becoming brittle when below freezing. In very cold weather, the cable should be

handled with care so as not to damage the jacket or insulation when unreeling,

flexing and installing. The method of measurement of signal cable is shown in TEM

Figure 498-16.

- Interconnect cable is used as the

connection between intersections for systems of signals (although there is

no significant difference between signal and standard interconnect cable).

The cable may be either IMSA 19-1, IMSA 20-1 or IPCEA S-61-402 as in

signal cable, or twisted pair/shielded interconnect cable conforming to REA

PE-39 may be required by the plans.

Twisted pair/shielded cables are less prone to pick up induced current

as a result of nearby electrical devices or magnetic fields, and are necessary

for certain types of communication systems which may be used to interconnect

signals. The number of conductors and wire gage shall be as specified. It

should be noted that in the case of twisted pair/shielded cable, the number of

conductors is typically referred to as the number of pairs (pair count), i.e.,

sixconductor cable would be referred to as a three-pair cable. Conductors shall

be of copper and are usually solid.

- Interconnect cable of the integral

messenger type is aerial self-supporting cable with a "figure 8"

cross section. The cable may be either IMSA 19-3, which has a jacket of

polyvinyl chloride, or IMSA 20-3, which has a polyethylene jacket.

Shielded versions, IMSA 19-4 and IMSA 20-4, may be required by the plans.

The number of conductors and wire gage shall be as specified. Conductors

shall be of copper and stranded, and conductor insulation shall be color coded.

Twisted pair/shielded interconnect cable of the integral messenger type

conforming to REA PE-38 may also be required by the plans.

- Loop detector wire is laid in turns in

saw slots cut into the pavement and routed by the groove to the edge of

pavement and to a pull box. The wire is single-conductor No. 14 AWG.

The conductor shall be of copper and stranded. Loop detector wire

consists of detector wire inserted into a flexible plastic tubing (CMS 732.19)

meeting specifications IMSA 51-5. The tubing shall encase the wire completely

from the splice at the lead-in cable through the entire loop turns and back to

the splice.

- Lead-in cable for detector loops is

spliced to loop wire and routed to detector units in the controller

cabinet. The cable shall be two-conductor No. 14AWG with jacket of 0.04

inch (1 millimeter) minimum black polyethylene and insulation of

polyethylene. Each conductor shall be stranded copper. The conductor pair

shall be twisted and shielded.

- Lead-in cable for magnetometers is

spliced to the lead which is a part of magnetometer probes and routed to

detector units in the controller cabinet. The cable is four-conductor No.

18 AWG with a jacket of 0.026 inch (0.66 millimeter) minimum high density

polyethylene and a low capacitance insulation. Each conductor shall be

stranded copper, and insulation shall be color coded. The four conductors

shall be twisted.

- Power cable is used as the connection between

the service pole or service drop and the controller cabinet. The cable

normally is two-conductor and UL:RHH/RHW/USE type. The wire gage shall be

as specified. Conductors shall be color coded, of aluminum and stranded.

Stranded copper may be substituted with an AWG one gage higher (wire

one size smaller).

When specified, power cable may be three conductor. Single conductor

cables may be substituted for a two (or three) conductor cable, but color

coding should still be provided.

- Service cable is used to bring power to

the vicinity of an isolated intersection. The cable is normally

two-conductor (duplex) and XHHW type or cross-linked polyethylene with a

0.045 inch (1.14 millimeter) minimum jacket. The wire gage shall be as

specified. The cable is aerial self-supporting with one conductor being an

uninsulated ACSR (aluminum conductor, steel reinforced) messenger wire. An

insulated conductor of stranded aluminum is twisted around the messenger.

Stranded copper with an AWG one gage higher (wire one size smaller) may be

substituted for the aluminum conductor. Three-conductor (triplex) may be

specified where two insulated conductors are twisted around the messenger

wire. The uninsulated messenger serves as the grounded neutral of the

power supply.

- Ground wire is used to connect signal or

sign supports to ground rods. The wire shall be single-conductor No. 4 AWG

made of seven-strand soft drawn copper with white insulation and rated at

600 volts. The wire is used as part of the CMS 625.09

Ground Rod item.

632-8.6 Lashing of Overhead Cable

A preformed helical

lashing rod shall be of the proper internal diameter to tightly secure overhead

cable(s) to the messenger wire. A lashing rod should not be loose or so tight

as to be impressed deeply or cut into the cable jacket. If either deficiency is

observed, the proper internal diameter may be determined by the following

formula: C approx. = (0.85) (D+m), where C is the lashing rod internal

diameter, D is the cable jacket diameter and m is the messenger wire gage (all

dimensions in inches (millimeters)).

For groups of

several cables of varying diameter, the internal diameter of the lashing rod

may be best determined by a graphic layout to scale.

Signal cable routed

on messenger wire should neatly pass the bull rings in its path. Also, signal

cable routed around an aerial corner formed in the span wire at a bull ring

should have a radius in its routing small enough to form a tangency with the

bull ring.

632-8.7 Cable Support Assemblies

As shown in TEM

Figure 498-14, a

cable support assembly makes use of a flexible tubular wire mesh device called

a cable grip which has a gentle holding action over its length and which is

used to eliminate strain or damage to the jacket of cable(s) hanging in the

interior of poles.

The support assembly

consists of the grip attached to a single “U” eye support bale and a sling when

necessary. The grip may be used on an individual cable or a group of cables up

to a maximum of four (CMS 632.21).

The grip shall be the proper size and strength for the cable(s), of stainless

steel or tin coated bronze, and may be either a “closed” or “split with rod”

type. The split type is used when a cable end is not available. In this

application, the grip mesh is not a continuous tubular weave, but is split for wrapping

around the cable(s) and is secured by a rod which is inserted through alternate

weaves at each side to form a tube.

The support’s bale

shall be hung over the pole J-hook if sufficient length is available;

otherwise, a sling shall be made of messenger wire, clamps and thimbles. The

sling wire is to be passed through the bale eye, adjusted to the proper length

and hung on the J-hook.

Pole interiors

should be checked by removing pole caps to verify that cable support assemblies

are in place, hung on the J-hook and properly adjusted to eliminate cable

jacket strain.

632-8.8 Aerial Interconnect Cable

For aerial

interconnect cable, the following standards and guidelines apply:

- Aerial interconnect cable and

accessories shall comply with SCD TC-84.20

(illustrated in part in TEM Figure 498-15).

Interconnect cable may be supported on separate messenger wire or be the

integral messenger self-supporting type with a "figure 8” cross

section, if specified on the plans.

- Metal poles with messenger wire

supported interconnect cable are to be furnished with pole clamps. The

pole clamp may provide clevis(es) to which the messenger is attached and

terminated, or may provide a stud to which a clamp assembly can be bolted.

- Messenger wire ends are to be looped and

secured with three-bolt clamps or a messenger vise, or a preformed guy

grip dead end may be used (see Section 632-8.4). If clamps or vises

are used, the wire tail shall be served (see Section 632-8.3).

Thimbles with a correct groove size for the messenger wire shall be used

to connect to the clevis of the pole clamp.

- When messenger wire is to be grounded to

a metal pole, a ground clamp, an insulated ground wire and a bolt tapped

into the pole shall be used (also see item 10 in this section).

- Wood poles with interconnect cable shall

be fitted with through-bolts holding a clamp assembly or with a thimble

eye-bolt to which the messenger may be attached and terminated.

- The clamp assembly shall be suitable to

the type of cable support, either messenger wire or self-supported cable

with "figure 8" cross section. Clamp assemblies for "figure

8" interconnect cable differ slightly from those intended for use

with separate messenger, inasmuch as the clamp used with "figure

8" must allow a small gap for the web of the "figure 8"

cable which joins the messenger to the cable.

- When messenger wire or "figure

8" cable is to be grounded on a wood pole, a ground clamp and an

insulated ground wire stapled to the pole and covered by a molding shall

be used (also see Item 10 in this section). The ground clamp used with

"figure 8" cable shall be a type with teeth to penetrate the

jacket over the messenger. The ground wire shall be bonded to an existing

ground wire or to a ground rod.

- Standard interconnect cable shall

conform to CMS Table 732.19-1

and have the number of conductors and wire gage specified. There is no

difference between standard interconnect cable and signal cable, only in

the application. Interconnect cable of the shielded type may be specified

in the plans. The interconnect cable should be marked with the correct

nomenclature. Solid conductors are not permitted (CMS 732.19)

unless specified in the plans. Splices may be used on long lengths of

interconnect cable (CMS 632.23)

and shall be accomplished only in weathertight splice enclosures. Splice

enclosures may be either aerially located on the messenger wire or be a

pole-mounted box type (see SCD TC-84.20).

Where the aerial enclosure is clamped to the span, it should be within 2

feet (0.6 meter) of a pole to improve accessibility. No measurement

allowance is given for splices.

- Aerial interconnect cable is to have a

sag between three to five percent of pole spans or is to match existing

utility lines.

- Messenger wire supporting interconnect

cable, and the integral messenger of self-supporting type cable, is to be

grounded in cable runs at the first and last poles and on intermediate

poles at intervals not to exceed 1200 feet (366 meters) (also see item

4 of this section for grounding on metal poles, and item 7 for

grounding on wood poles).

- As temperatures decrease, interconnect

cable gets stiffer and harder, becoming brittle when below freezing. In

very cold weather, the cable should be handled with care so as not to

damage the jacket or insulation when unreeling, flexing and installing.

- Standard interconnect cable may be

attached to supporting messenger wire by lengths of preformed lashing rod

or by spinning wire. Lashing rods shall be of the proper internal diameter

to snugly hold the cable but not cut into its jacket (see Section

632-8.6).

- Aerial interconnect cable of the

integral messenger self-supporting type (with a "figure 8” cross

section) shall have its wind stability increased by being twisted or

spiraled once every15 feet (4.6 meters) of span. This is done by clamping

the tensioned cable to every other pole and then going to intermediate

poles and twisting the cable before tightening their attachment clamps.

- When the interconnect cable is attached

to a pole and continues in a relatively straight line past the pole, this

is an intermediate support; whereas, if the interconnect cable turns at

the pole, it is a corner or turning point. Certain types of clamps may be

well suited for intermediate support applications, while other designs are

required for corner clamps. The clamps shown on the left side in SCD TC-84.20

are usually not suitable for corner clamps if the change of direction is

more than about 10 degrees. See SCD TC-84.21

when the change of direction is more than about 10 degrees.

632-9 Method of Measurement for Cable and Wire

TEM Figures 498-16 through 498-20 illustrate the method of measurement for

signal cable, interconnect cable, detector lead-in cable, power cable and

service cable, respectively. CMS 632.29

also specifies the method of measurement for cable and wire.

632-10 Signal Equipment and Wiring

632-10.1 General

This section will be

used to provide additional information about other signal equipment and wiring.

632-10.2 Controller Cabinet

While the layout of

controller cabinets may vary, the following requirements and guidelines apply:

- The prewired cabinet should be checked

against approved catalog cuts, the wiring diagram for the cabinet and the

plans.

- The cabinet should be fitted with a

small door-in-door (police door) unless otherwise specified. The cabinet

should be in good condition, revealing no evidence of damage, with its

material free of cracks and pinholes. The doors and seals should fit

properly. The cabinet exterior should appear as metallic aluminum unless a

color is specified. The cabinet interior may be similar to the exterior or

may be flat white. The method of cabinet mounting should be as shown on

the plans and the cabinet should be securely mounted.

- Cabinets equipped with solid state

controllers shall be provided with a suitable number of sturdy adjustable

metal shelves to mount the specified equipment and to provide the required

space for designated future equipment (CMS 733.03).

- The equipment shall be arranged for easy

withdrawal and replacement, without the necessity of disturbing adjacent

equipment. The permanent location of equipment within the cabinet, as well

as the shelves themselves, should allow free circulation of air and not

restrict air flow from fan ducts or vents. Components on shelves and

devices on the door shall be arranged so that a 1 inch (25 millimeters)

minimum space separates them when the door is closed. This minimum space

shall not be compromised by plugs, wires, controls or similar items.

Terminals and panel-mounted devices with exposed contact points located

next to shelf mounted equipment shall be provided with spacers, shelf lips

or other means to assure that component units cannot be accidentally moved

into contact with any exposed electrical terminal points. A minimum 4

inches (100 millimeters) clear area from the bottom of the cabinet should

be reserved for the routing of cables. No shelf, component or

panel-mounted item shall be located in the bottom 6 inches (150

millimeters) of cabinets, with the exception that terminal blocks only in

pedestal or pole mounted cabinets may be installed as close as 4 inches

(100 millimeters) to the bottom.

- Ready accessibility should be provided

for items such as load switches, flasher, relays, terminal blocks and

fuses which are mounted on or plugged into panels on the cabinet back or

sides. Switches, controls and indicator lights should be easily operable

and visible without having to move equipment from their positions.

- Major equipment items should bear a name

plate, brand or indelible marking for identification as to type, model,

catalog number and manufacturer’s name or trademark.

- The furnished controller unit should be

checked for the correct type, number of phases, and available control

functions required by the plans. Controller units should be furnished with

all auxiliary equipment necessary to obtain the operation shown in the

plans.

- When specified, other equipment may be a

part of the prewired cabinet, such as: a coordinator, an on-street master,

interconnection equipment, preemption equipment, time clock or weekly

programmer, and special relays.

- Furnished detector units should be

checked to see if the correct quantity is installed, and the proper type

used with each loop and each detector phase. When multi-channel detector

units are furnished, the plans may require the provision of special

cabinet wiring and an adapter harness to allow single channel detector

units to be readily substituted.

- The prewired cabinet should also be

checked for the following auxiliary equipment:

- A forced air ventilating fan

automatically controlled by a thermostat shall be furnished.

- A conflict monitor shall be furnished.

When the plans so specify, according to CMS 733.03(A.2.c.),

an increased capability monitor shall be furnished. The minimum number of

monitor channels, related to the number of phases for the intersection,

should conform to CMS 733.03.

- Load switches should be provided in

sufficient quantity for the interval sequence shown in the plans. The

switches shall be solid state NEMA triple signal type with input

indicator lamps. The minimum number of load switch sockets furnished,

related to the number of phases for the intersection, shall conform to

CMS 733.03.

- A flasher (or flashers) shall be solid

state NEMA type.

- Relays required for the proper

operation of the specified equipment shall be furnished.

- Lightning protection devices shall be

furnished for the protection of solid state controllers. They should be

located on the incoming power line and on loop detector leads where these

connect to the terminal block. When solid state coordinators are

furnished, they should be protected by devices across each conductor and

ground on the interconnect cable (see CMS 733.03(A.2.f.)).

- A convenience outlet and lamp shall be

furnished. The outlet should contain at least one standard three-wire

plug receptacle of the ground-fault circuit-interrupting type. The lamp

should be an incandescent type, located in the upper part of the cabinet,

and controlled by a switch.

- A main power breaker shall be

furnished. The fan, convenience outlet and lamp should be wired on a

branch of the AC+ power line preceding the main breaker, so that these

may be operated independently of the main breaker control. This preceding

branch should itself contain an auxiliary breaker rated at 15 amp.

- A radio interference filter should be

installed in the incoming AC+ power line between the main breaker and

solid state equipment. If the equipment furnished does not provide signal

and flasher circuit switching at the zero voltage point of the power line

sinusoid wave form, filters should also be provided for the load switches

and flasher.

- A manual control cord with push button

should be furnished only when the plans so require (CMS 733.03).

The cord should be at least 5 feet (1.5 meters) long.

- Switches required for the proper

operation of specified equipment should be furnished and labeled as to

function and setting position. The following switches should be grouped

behind the small door-in-door (police door): signal shutdown switch,

flash control switch and an automatic/manual transfer switch (when manual

control is specified).

- Terminal blocks should not be

obstructed by other equipment. Terminal points should accept spade type

wiring terminals except for incoming power terminal points which may be

either the type to accept bare wire or spade terminals. Contact between

adjacent terminal points may be either by bus bar or by wire jumpers with

spade terminals.

- The incoming power bus should be fed

from the line side of the incoming 120 VAC power line after the circuit

has passed through the main power breaker. A signal bus relay should

control power to the bus supplying power for the signal load switches. The

requirement for radio interference filters (CMS 733.03)

should be adhered to, with the buses supplying load switches and flashers

being filtered if load switches do not switch at the zero voltage point of

the power line sinusoid wave form. A common terminal bus insulated from

the cabinet should be furnished for the connection of the neutral wire of

the incoming 120 VAC power line. This common bus should have sufficient

terminal points to accommodate all potential cabinet wiring as well as

field wiring. A separate common terminal, insulated from the panel, should

be used for the interconnect common (if interconnection is a part of the

system).

- The cabinet should include a ground bus

bar with an adequate number (at least three) of ground terminal points

(CMS 733.03).

This bus bar should be grounded to the cabinet. The ground bus bar will

normally be bonded to the common terminal bus using at least a No. 8 AWG

copper wire.

- Wiring bundles should be neatly arranged

and grouped as to voltage and function, and they should be lashed or

restrained so that they do not interfere with the access to equipment,

including terminal blocks or buses. The harnesses should be of sufficient

length and should be easily traced through the cabinet. All conductors

should be stranded, with labeled spade type terminals or plug connectors.

The wiring should be color coded, with solid white for the AC common,

black for the AC line side power (AC+), and solid green or white with

green stripes for the safety ground.

- Incoming cable and wire should be

identified by tags or bands (CMS 632.05).

The size, material and method of tag or band identification should be in

accordance with CMS 713.18(B),

except that marking may be by indelible pen on plastic tags instead of

embossed letters. The identification on the tags or bands should conform

to the wiring diagram for the cabinet and its intersection, with typical

abbreviations in accordance with the Table in CMS 632.05

(reproduced in Table 497-2).

- Two copies of the schematic and wiring

diagram for each cabinet and its intersection should be furnished by the

contractor. The diagrams are to be updated to reflect any changes made

during construction. The diagrams should be neat and legible, on durable

paper, and folded in a moisture-proof envelope fastened to the cabinet

interior.

632-10.3 Cable and Wire Identification

As noted in CMS 632.05,

cables and wires shall be identified as shown in TEM Table 497-2.

632-10.4 Vehicular Signal Heads and Wiring

Illustrations of the

signal head visors, hangers and wiring discussed herein are presented in TEM

Figure 498-21.

- Signal heads shall conform to the plans,

CMS 732.01

and SCD TC-85.20.

Signal heads shall have the correct number of faces (one-way, two-way,

three-way or four-way) and each face shall be made up of the correct number

of optical sections (one, three, four or five). Sections shall be of the

correct lens size, i.e., 8 or 12 inches (200 or 300 millimeters), color

and ball or arrow configuration. Arrow lenses are only to be the 12 inch

(300 millimeter) size. It should be noted that arrow lenses are made in

Rights, Lefts and Throughs (up). The use of the proper arrow lens should

be checked.

- Lenses shall be aligned properly in

their frames so their optical configuration directs most of the light to

the forward sector.

- As noted in TEM Section 420-4.2,

signal heads shall have a yellow finish, unless otherwise specified in the

plan.

- Cutaway type visors (CMS 732.01)

shall be fastened to each optical section, unless open bottom tunnel

visors or other types are specified, and the interior finish of the visors

shall be flat black.

- Signals should be clean and the assembly

tight. Gaskets should be in good condition and lens door hinges and

latches should be in good working order. All openings not used for

mounting purposes shall be closed by waterproof caps.

- Five-section faces, arranged in

accordance with SCD TC-85.20

and the plans, are to use galvanized pipe, elbows and tubular hardware,

painted to match the signal head.

- Swinging signals shall be installed in a

plumb condition. A balance adjustor should be used only when necessary to

achieve plumb (CMS 632.06).

- Swinging signals suspended from a mast

arm shall be fitted with a universal hanger permitting swinging in both

longitudinal and transverse directions (CMS 632.06).

- When specified by the plans, disconnect

hangers shall be used with signal heads.

- Drop pipes, 1 1/2 inch (38 millimeters)

diameter galvanized pipe, are a source of trouble and are aesthetically

unattractive; therefore, they are intended to be used only when they are

necessary to permit signals to be suspended above the roadway within a

clearance of 16 to 18 feet (4.9 to 5.5 meters). Signals supported by span

wire, with sag required between 3 and 5 percent (SCD TC-84.20),

shall be brought to proper clearance by adjusting the attachment height of

the span wire to the poles. Because of the 2 foot (0.6 meter) clearance

tolerance, drop pipes should not be necessary in most cases.

- When the plans so specify, backplates

shall be fitted to signal heads.

- Signal cable shall be routed into the

interior of heads through the entrance fitting using a grommet. The cable

shall be routed to each face’s terminal block, which is typically in the

yellow indication section but may be in the green section. Conductors

shall be fitted with spade type terminals and shall be fastened securely

to the correct terminal points. Conductors shall be identified according

to the wiring diagram. Signal cable shall not be spliced, either between

signals or in signal face interiors.

- External signal cable shall to be

fashioned into a drip loop extending at least 6 inches (150 millimeters)

below the entrance fitting but shall not chafe on the signal.

- Lamps for 8-inch (200 millimeters)

yellow lenses shall be 550 lumens (minimum initial) or 70 watts (maximum

input), lamps for 8-inch (200 millimeters) green or red lenses shall be

1260 lumens (minimum initial) or 116 watts (maximum output), and lamps for

12-inch (300 millimeters) lenses shall be 1650 lumens (minimum initial) or

150 watts (maximum input), unless otherwise specified (CMS 732.04(B)).

The light center length for lamps suitable for 8-inch (200 millimeters)

lenses is 2 7/16 inches (62 millimeters), and for lamps suitable for

12-inch (300 millimeters) lenses, this length is 3 inches (76

millimeters). The light center length is measured from the tip of the base

to the approximate center of the filament. Lamps shall have a clear glass

envelope and a rated life of 8000 hours. Lamp sockets shall be rotated so

as to position the open portion of each lamp filament in an upward

position. All vehicular signal lamps shall be prequalified in accordance

with CMS 732.04(B).

- Each face of a signal head shall be

oriented to its approach of traffic and its locking device securely

tightened. Orientation or aiming of standard signals should be done so

that the maximum light intensity from a standard signal is directed

slightly below the horizontal center; thus, on a level approach, the face

of the signal should be essentially vertical. When an approach to a signal

is on a grade, the signal may be tilted slightly to point the signal axis

parallel to the grade of the approach. Horizontal aiming should orient the

axis of signal display parallel to the centerline of the approach for

straight approaches when the signal is over the roadway. When the approach

roadway is curved, or when a signal is not over the roadway, the axis

should be directed at a point on the approach which is 175 to 625 feet (54

to 191 meters) in advance of the intersection, the distance being

dependent on the speed of approaching traffic. For convenience, OMUTCD

Table TS-1 has been reproduced in part as TEM Table 497-3.

- When a vehicular traffic signal head has

been erected and faces approaching traffic, it shall either be in

operation as a stop-and-go signal or a flasher, or it shall be covered or

bagged. This is an OMUTCD requirement (OMUTCD Section 6B-19) and cannot be

ignored. Typically, the plans will contain an item for “Covering of

Vehicular Signal Heads” which will require the contractor to cover,

maintain the covering, and subsequently remove the covering when the

signal is ready to commence operation.

- Normally, the plans will provide the

“covering” item for each new signal head, but will not provide them for

any existing heads which are to be removed. The intent is that “covering”

will be necessary for the new heads until they and their associated

controller and wiring have been checked by circuit testing (see Section

632-10), while any existing signals at the intersection will continue

to control traffic. When the new signals are uncovered and placed in

operation, the existing signals can be quickly removed. Specific

maintenance of traffic requirements in any plan may require a different

means to assure the unused signals are not exposed to traffic.

632-10.5 Optically Programmed Signal Heads

Programmed heads (see

TEM Section 420-4.6) shall conform to approved catalog cuts, CMS 732.02

and 732.03,

and the plans. They are to have the correct number of optical sections making up

each face. Programmed heads have many points of similarity to regular heads.

Items 2, 3, 5, 11, 12, 13, 16 and 17 of Section 632-10.4 also apply to

these signal heads. For more detailed information, see publications by the

manufacturer.

Each optical section

shall be fitted with a visor (CMS 732.02

and 732.03)

and the interior surface of visors shall have a flat black finish.

Programmed heads

shall be mounted in a manner permitting little or no motion. If mounted on a

mast arm, a rigid adapter shall be used. Heads of more than three vertical

sections mounted on a mast arm shall be fitted with pipe backbracing, as shown

on SCD TC-85.20.

The pipe shall be a minimum of 17 inches (430 millimeters) behind the signal

center axis so that adequate clearance is provided for the programming

procedure. If heads are supported by span wire, a tether messenger wire shall

be attached to a fitting in the bottom of the signal’s lower section.

Customarily the

manufacturer’s representative will program the signals, but in accordance with

the plans, the contractor is responsible for the correct aiming and masking of

the signal so as to be visible to drivers or pedestrians only in the area

indicated on the plans.

Signals are

pre-tilted to cover most situations. The yellow indication section should be

aimed first and the other sections aimed similarly. The housing shall be opened

and the lamp collar and diffuser removed. The roadway inverted image should be

observed on the surface of the glass with the eye held a distance of 2 feet

(0.6 meter) behind. The image observed is where the optics are pointed. The

tilt of the integral adapter shall be adjusted so the horizon appears at the

lower third of the glass. The adapter screws are then to be tightened. All

sections shall be at the same tilt angle.

The signal shall be

rotated horizontally so the image on the glass covers the proper roadway

lane(s). The bolts of the mounting adapter shall be loosened and the signal

rotated around its serrated surface. The movement of traffic should be examined

on the glass. When the roadway image appears correct, that is, pointed in the

direction where it should be seen, all screws may be tightened. All sections of

the signal should now be adjusted and rigid in their mountings, properly aimed

and ready for masking.

The yellow

indication section of the signal should be masked first since it transmits a

brighter image. The other colors can then be masked identically.

Masking requires the

use of opaque tape furnished by the manufacturer. The tape shall be applied to

the glass, up to the edge, and squeegeed flat to remove air bubbles. The tape

initially should be applied horizontally to the glass to cover the image of the

sky and that portion of the roadway which is distant. After this is done, tape

should be applied to the images on the sides of the lane(s) where the signal is

not to be visible. In many cases, signal visibility is desired for a left turn

lane only, and visibility to the adjacent through lane should be masked. Excess

tape extending beyond the edge of the glass should be trimmed away, taking care

not to cut on the surface of the glass.

The reduced area on

the glass should be checked to verify that its image is the only area in the

roadway which should see the signal. The lamp collar and diffuser may now be

replaced and the housing latched.

The boundaries of

the area in the roadway where the signal is to be visible should be explored on

foot to verify that the head is properly programmed.

632-10.6 Pedestrian Signal Heads

Pedestrian signal

heads shall conform to CMS 732.05,

approved catalog cuts, the plans and SCD TC-85.10.

Signals shall have the correct type of light source and lettering height in

accordance with the plans (CMS 632.08).

Housings shall have

a black finish, unless otherwise specified (CMS 732.05).

Visors shall be fitted over each message, except one type may have the entire

face protected by a flat black sunshade fastened close to the lens. The

interior surface of visors shall be flat black finish. Signals should be clean

and the assembly tight. Gaskets should be in good condition and lens door

hinges and latches in good working order.

Housings shall be

positioned with a minimum set back of 2 feet (0.6 meter) from the curb and a

height of 8 to 9 feet (2.4 to 2.7 meters) above the sidewalk for adequate

clearance. The heads shall be oriented toward their crosswalk and locked

securely in position.

Lamps for

incandescent signal heads of the 8-inch (200 millimeters) lens type shall be

1300 lumens (minimum initial), and for the 12-inch (300 millimeters) lens type

shall be 1650 lumens (minimum initial), unless otherwise specified.

Pedestrian push

buttons shall conform to Section 404-2, approved catalog cuts, and CMS 732.06.

Push button housings shall have a yellow finish, unless otherwise specified.

The push button shall be positioned 3.5 to 4 feet (1.1 to 1.2 meters) above the

sidewalk.

Push buttons on metal

poles shall be installed over a 3/4 inch (19 millimeters) maximum field drilled

hole with edge protected by two coats of zinc-rich paint and a rubber grommet

inserted.

The push button

housing curved back shall be positioned over the hole, wiring routed through to

the electrical mechanism and the housing secured by stainless steel screws.

Unused holes in the housing shall be plugged. Push buttons on wooden poles

shall have their wiring in conduit connected to a fitting of the signal

support.

Signal head supports

(conduit and fittings) on wooden poles shall be grounded, using a ground clamp

and an insulated ground wire stapled to the pole and covered by a molding.

OMUTCD Section 2L-3

addresses standards for the signs used where push buttons are provided to

actuate pedestrian signals. The sign legend shall conform to the plans.

632-10.7 Loop Detector Slot and Wire

TEM Figures 498-23 and 498-24 illustrate details related to the following

discussion of loop detector slots and wiring.

- Slots cut into the pavement forming

rectangular detection loops shall be in accordance with the plans and SCD TC-82.10.

- The slots shall be a minimum of 3/8 inch

(9.5 millimeters) in width and shall have a minimum depth of 2 inches (50 millimeters)

in concrete and 4 inches (100 millimeters) in asphalt concrete. SCD TC-82.10

requires that loop corners be made at a drilled or bored hole, about 1 1/4

inches (32 millimeters) in diameter, and with the same depth as the saw

slot. Any sharp edges at the saw slots and the holes shall be chiseled

out.

- The slot depth shall accommodate the

specified number of turns of wire laid so that the uppermost wire has a

covering of at least 3/4 inch (19 millimeters). The number of wire turns

shall comply with the plans and the table in SCD TC-82.10

(also shown in Figure 498-23). A

separate slot leading from the loop to the pavement edge is typically cut

for each loop.

- When permitted by the project engineer,

loops installed in new asphalt concrete may be sawed and the loop wire(s)

embedded with sealant in a subsurface course with subsequent covering by

the surface course.

- Some plans may specify the use of

preformed loops placed on the pavement for covering by a surface course of

asphalt concrete.

- If the problem of loop installations in

brick streets is encountered, the project engineer should consult with the

local traffic engineer for recommendations.

- Loop locations may be adjusted to avoid

manholes. Loops should not be placed across pavement joints. Instead,

lateral and longitudinal adjustments should be considered, with the

approval of the project engineer. If joint crossing is unavoidable or

major pavement cracks are encountered, the following techniques may be

used (see Figure 498-24).

- In Technique A, the loop wires are laid

over the joint or crack within a 3 inch (75 millimeters) square or

circular hole cut to slot depth. The wires are laid in an “S” shape and

the hole filled with elastic joint material or asphalt concrete.

- In Technique B, the slot at the joint

or crack is saw cut to twice-normal width and depth. The wires are laid

so as to conform to the deepened slot which is injected with soft setting

butyl rubber up to the depth of the original slot. The original slot

depth and the remaining perimeter of the slots are embedded with standard

sealant cured to a flexible state.

- In Technique C, the slot at the joint

or crack is enlarged. The wires are encased in a length of plastic tubing

which should be large enough to loosely hold all wires and may be slit

lengthwise to facilitate construction. Before placing it in the slot, the

ends and the longitudinal slit are to be taped shut to prevent the entry

of loop sealant. The enlarged slot is then filled with loop sealant.

- Before loop wire is placed, all slots

shall be brushed, blown clean of loose material and completely dry.

- Loop detector wire shall be

single-conductor No. 14 AWG insulated wire, type IMSA 51-5 with stranded

copper conductors, unless otherwise specified. The wire should be marked

at intervals with the wire gage, UL label and type. The detector wire is

contained inside a flexible plastic tube, as required by IMSA 51-5.

- The correct turns of loop wire (TEM

Figure 498-23),

up to a maximum of four, shall be placed in the slots, to comply with CMS 632.23

and the plans. The wire shall be pushed to the bottom of the slots with a

blunt wooden tool (or equivalent) to avoid damaging the insulation.

- The wires with tubing at the pavement

edge or curb shall be led into a conduit of the size shown in SCD TC

82.10. Care should be taken to prevent excessive slack at the point

where the wires enter the conduit. The high end of the conduit shall be

sealed in accordance with SCD TC

82.10.

- The detector wire shall be twisted in

the conduit leading from the pavement edge to the pull box. The flexible

plastic tubing shall cover the wire completely from the splice at the

lead-in cable, through the entire loop turns and back to the splice. The

tubing provides extra protection from abrasion and allows the wire to

slide inside the tubing in case of pavement shift or cracks, thus

minimizing the possibility of breakage. Since wire/tubing includes an air

pocket, it will tend to float to the surface when sealant is applied to

the slot. For this reason it is usually necessary to wedge short lengths

of the tubing, or similar devices, into the slot to wedge down the

tubing/wire. These are usually needed at 1 to 2 foot (0.3 to 0.6 meter)

intervals.

- The slots shall be completely filled

with approved sealant and left undisturbed until cured to a flexible

state. Sealants on the ODOT prequalified

list shall be used, in accordance with the manufacturer’s recommendations.

Materials which set up to a hard or brittle state are not acceptable.

- Detector loops are measured as “each”

loop installed and the item includes wire, pavement cutting and sealant.

632-10.8 Loop Detector Lead-In Cable

Unless otherwise

specified, loop detector lead-in cable (CMS Table 732.19-1)

shall be two conductor No. 14 AWG twisted pair shielded, with a jacket of black

polyethylene 0.04 inch (1 millimeters) thick minimum, and polyethylene

insulation with conductors of stranded copper.

Within the pull box,

loop wire ends shall be joined to the conductors of the lead-in cable by

soldering and covered with insulating material (see TEM Figure 498-25). An approved,

poured epoxy waterproof splice kit shall be used. It is understood that epoxy

splice kits are easily damaged by freezing temperatures encountered prior to

mixing. Damaged epoxy components may sometimes be recognized if either of the

components has turned or is streaked milky white.

Lead-in cable shall

be routed to the controller cabinet, fitted with soldered spade type terminals

and fastened to the correct points of the terminal block. The lead-in cable’s

shielding shall be grounded to the ground bus within the cabinet.

If a pull box is not

specified on the plans, the splice between the loop wire and lead-in cable

shall be made in the first entered pole or pedestal, except where the

controller cabinet is mounted on the pole or pedestal. If the controller

cabinet is mounted on the pole or pedestal, the loop wires may be routed

directly into the cabinet and no lead-in cable is necessary.

Loop detector

lead-in cable is measured in accordance with Section 632-9 and TEM

Figure 498-18.

The poured epoxy

splice in the pull box is included.

632-10.9 Magnetometer Probes and Lead-In

Magnetometer sensor

probes (TEM Figure 498-26)

may be set in the pavement, or under and in bridge decks in accordance with

SCD TC-82.10

at the locations shown on the plans.

Although core

drilling may be performed after concrete placement, it is preferred that probe

holes in new concrete be formed by pouring concrete around a vertical piece of

capped vinyl-chloride or other non-metallic tubing. Probe holes in existing

concrete must be core drilled. Probe installations under bridge decks may be as

shown in Figure 498-26. The lead from probes should be in non-metallic

conduit. Probes in bridge slabs should be centered in the reinforcing steel

grid square which is nearest to the probe’s plan location. The center of a grid

square may be located by the use of a Pachometer metal locator. The procedure for

use of such an instrument is given in Section 632-10.10.

Probe holes in

pavement and bridge decks shall be approximately 3/4 inch (19 millimeters)

greater than the probe diameter. The probe shall be set so as to have a covering

of at least 1 ½ inches (38 millimeters). However, deeper placement may be used

if recommended in the manufacturer’s instructions.

The probe lead,

which is a part of the probe(s), is to be led from the probe(s) to the edge of

pavement, to the bridge parapet wall or under the bridge deck, depending on the

design used.

When in pavement and

bridge decks, the slot for the lead shall be a minimum of 3/8 inch (9.5

millimeters) in width and have a depth of 2 inches (50 millimeters) in concrete

and 4 inches (100 millimeters) in asphalt concrete.

Probe holes and

slots are to be brushed, blown clean of loose material and completely dry. The

probes are to be set and leads pushed to the bottom of slots with a blunt

wooden tool (or equivalent) to avoid damaging the insulation. Probe holes and

slots are to be completely filled with approved sealant and left undisturbed

until cured to a flexible state. The sealant should be the same as for loop

detector slots, as given in Section 632-10.7.

Probe leads in slots

at the pavement edge or curb shall be led into a 3/4 inch (19 millimeters)

conduit connecting to a roadside pull box. Care should be taken to prevent

excessive slack at the point where the lead enters the conduit. The high end of

the conduit is to be sealed in accordance with SCD TC-82.10.

Unless otherwise

specified, lead-in cable (CMS Table 732.19-1)

shall be four-conductor No. 18 AWG color coded, twisted, with a jacket of 0.026

inch (0.66 millimeters) minimum high density polyethylene and a low capacitance

insulation with conductors of stranded copper.

Within the pull box,

the probe lead ends shall be joined to the conductors of the lead-in cable by

soldering and covered with insulating material. An approved poured epoxy

waterproof splice kit shall be used. The kit should be the same as for loop

detector lead-in cable as given in Section 632-10.8.

Lead-in cable shall

be routed to the controller cabinet and fitted with soldered spade type

terminals and fastened to the correct points of the terminal block. The

shielding of lead-in cable shall be grounded to the ground bus within the

cabinet.

The installation of

magnetometer probes includes: the probe(s) and lead, the provision of probe

holes and pavement slots when used, sealant for the probe holes and slots, and

plastic conduit where required. Probes are measured as individual units with

the attached lead. Several probes may be on a single lead.

Magnetometer lead-in

cable is measured in accordance with Section 632-9 and TEM Figure 498-19. The poured

epoxy splice in the pull box is included.

632-10.10 Use of Pachometer Instrument

A Pachometer is an

instrument used to detect the location of metal such as reinforcement bars

under a concrete cover. The instrument is a magnetic detector which operates on

the principle of the change in magnetic flux due to the presence of ferrous

metal.

A probe is connected to the instrument and is passed

over the concrete surface being examined. The instrument will indicate when the

pole of the probe is parallel to and directly over the axis of a reinforcing

bar. Use of the instrument will, therefore, outline the sides of a grid square

for accurate magnetometer probe location in the center.

632-11 Signal Performance Tests and System Checks

632-11.1 General

Traffic control

signal components and the entire system shall be tested as required by various

specifications to assure proper operation before acceptance. Ground rods shall

be tested for satisfactory low resistance to ground. A circuit test should be

performed on all conductors to make sure there are no shorts, crosses and high

resistance or other improper connections. A cable insulation or megger test

shall be performed on all conductors to verify the integrity of the insulation

covering. All traffic control equipment in the controller cabinet should be

checked for correct settings and all controls manipulated for assurance of an

operable system.

Finally, the traffic

control system shall successfully pass a ten-day performance test, which will

give an opportunity for any hidden flaws to reveal their presence. As a final

“housekeeping” check, equipment should be observed for any evidence of

unattached ground wire, unlatched or unbolted doors, etc.

The results of the

various tests are to be entered by the contractor on test report forms (TEM

Form 496-6) as

required by CMS 632.28.

632-11.2 Ground Rod Test

All ground rods

shall be tested by the contractor for earth resistance to ground, as required

by CMS 632.28(B).

Testing is to be in accordance with CMS 625.19,

except that the measurement need not be made immediately after installation.

Testing shall be performed before the ground wire is attached.

The quality of a

ground rod installation varies greatly depending on the characteristics of the

earth surrounding the rod. Clay or mud provides the best ground connection

since they are dense and contain sufficient moisture and metallic salts to make

them conductive. Sand or gravel bearing earth is less conductive.

One type of test

equipment commonly used consists of two probes connected to an instrument

consisting of a modified Wheatstone Bridge for balancing resistances. As shown

in TEM Figure 498- 27,

the probes are pushed into the earth to form, with the rod, a triangle of equal

10 foot (3 meters) sides.

The general range of

the rod’s resistance to ground is investigated by initially setting a

potentiometer knob to its highest range control knob, selecting the ohm range

(1000, 100, 10 or 1) which permits the balance meter pointer to be

approximately centered in its dial by adjustment of the potentiometer knob. For

this general range selection process, the pointer is activated by depressing

the test button to a reduced sensitivity position.

For actual testing,

the test button is fully depressed, thereby giving maximum sensitivity for

final adjustment of the balancing potentiometer. The pointer is carefully centered

in its dial by means of the potentiometer knob, and the rod resistance to

ground read in ohms by the position of the potentiometer knob. For example,

with the range knob set at 10 and the meter centered with a potentiometer knob

setting between 1.2 and 1.3, the rod resistance to ground is 12 ½ ohms.

If the earth

resistance exceeds 10 ohms for signal controllers and tower lighting ground

rods, and 25 ohms for all other ground rods, the installation is unsatisfactory

and the contractor is required to proceed as follows (specified in CMS 625.09):

- A second rod shall be driven as shown on

SCD HL-20.11

and the two rods temporarily connected together with ground wire. The

earth resistance for the pair of rods shall be measured.

- If the earth resistance for the pair of

rods still exceeds the maximum, a 10 foot (3 meters) rod shall be

exothermically welded to the top of the second rod and driven into the

earth to form a continuous 20 foot (6 meters) long rod. The earth

resistance for the pair of rods, 10 to 20 foot (3 to 6 meters) long, shall

be measured.

- If the earth resistance still exceeds

the maximum, the procedure of lengthening and driving the second rod shall

continue until either an acceptable reading is achieved or the extended

rod cannot be driven further.

- If an acceptable reading cannot be

obtained after all the steps above, the contractor shall contact the

project engineer for instructions.

632-11.3 Short-Circuit Test

Before the

performance of any cable insulation (megger) test or the ten-day performance

test, a short-circuit test shall be performed by the contractor using a

volt-ohmmeter or other approved instrument (TEM Form 496-6 and CMS 632.28(C)).

Short-circuit tests shall be conducted with all electrical loads, power

sources, equipment grounds, and earth grounds disconnected (see TEM Figure 498–28).

Signal cable routed to signal heads may be tested with

connection made to the lamp sockets, but without the lamps being installed.

Each conductor shall

be measured against every other conductor and ground to assure that no

short-circuits, cross-circuits, or other improper connections exist. Continuity

should not exist between any conductor and any other conductor including

ground.

632-11.4 Circuit Continuity Test

Each circuit branch

shall be disconnected and tested by the contractor for continuity by

temporarily jumpering each branch at its termination and measuring the

temporarily looped circuit for assurance that no open circuits exist (TEM

Form 496-6 and CMS 632.28(D)).

This testing is illustrated in TEM Figures 498-29 through 498-32. Each circuit

branch should be according to plan, with no high resistance connections and