706.01 Non-Reinforced Concrete Pipe. Provide non-reinforced concrete pipe conforming to ASTM C 14 (ASTM C 14M), with the following modifications:

5.3 Does not apply.

6.2 Provide cementitious materials conforming to 701, except 701.07.

6.3 Provide aggregate conforming to the quality requirements of 703.02.

10.2 Ensure that the manufacture furnishes the number of pipe shown in the “Minimum Requirements for Sampling Materials” table, section 700.

10.3 In addition, perform external load crushing strength tests with hard rubber blocks on wood strips with plaster of paris bedding fillets.

13 Perform inspection at the project site. Obtain random samples from materials delivered to the project site or at other locations designated by the Laboratory. Ensure that the manufacturers of these materials are certified by the Office of Materials Management according to Supplement 1074.

15 Ensure that the markings also include “P” to denote non-reinforced pipe.

Testing Equipment. Ensure that every manufacturer furnishing concrete pipe under these Specifications furnishes all facilities and personnel needed to perform the tests.

706.02 Reinforced Concrete Circular Pipe. Provide reinforced concrete circular pipe conforming to ASTM C 655 (ASTM C 655M), with the following modifications:

Ensure that the minimum D-Load of the reinforced concrete pipe is as follows:

|

Size |

Minimum D-Load |

|

12 in (300 mm) |

2000 lb (100 kg) |

|

15 in (375 mm) |

2000 lb (100 kg) |

|

18 in (450 mm) |

1250 lb (62.5 kg) |

|

21 in (525 mm) |

1250 lb (62.5 kg) |

|

24 in (600 mm) |

1250 lb (62.5 kg) |

|

27 in (675 mm) or larger |

1000 lb (50 kg) |

1 In addition, ensure that this pipe is circular reinforced concrete pipe with circular or elliptical reinforcement, with and without quadrant and “S” strip reinforcement.

4.1 The acceptability of the pipe design is determined according to Section 10. All designs in ASTM C 76 (ASTM C 76M), Tables 2 through 5, inclusive, are accepted designs with the 0.01-inch (0.3 mm) crack D-loads as follows:

|

Table No. |

D-Load |

|

|

0.01-inch Crack |

(0.3 mm) Crack |

|

|

2 (Class II) |

1000 |

50 |

|

3 (Class III) |

1350 |

65 |

|

4 (Class IV) |

2000 |

100 |

|

5 (Class V) |

3000 |

140 |

All designs in Tables 706.02-1 through 706.02-4 are accepted designs with noted 0.01-inch (0.3 mm) crack and ultimate D-loads. For intermediate D-loads, in Tables 2 through 5 of ASTM C 76 (ASTM C 76M), steel areas for a given wall thickness may be interpolated between Tables 2 and 3, 3 and 4, and 4 and 5 for a size and D-load as accepted designs. Where different concrete strengths are listed in the tables, use the higher concrete. In addition, steel areas, interpolated as above between Table 706.02-1 and Table 706.02-2, 36-inch (900 mm) through 108-inch (2700 mm) using the higher concrete strength, and interpolation of the circumferential steel between Table 706.02-3 and Table 706.02-4 using the wall thickness and stirrup designs in Table 706.02-4, are accepted designs. Pipe manufactured according to an accepted pipe design will be accepted, at the option of the Laboratory, according to the basis of acceptance described in Section 4.1.1 or 4.1.2.

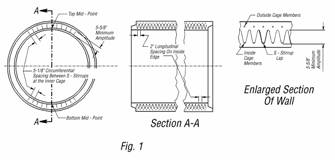

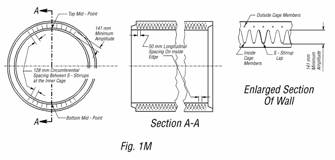

Provide reinforced concrete pipe with S-stirrups according to Figure 1 (Figure 1M) and the following requirements:

1. Provide steel conforming to 709.08, 709.10, 709.11, or 709.12. Ensure that the wall thickness, amount of circular reinforcement, S-stirrup system, and concrete strength comply with Tables 706.02-2, 706.02-3, and 706.02-4. Ensure that the spacing center-to-center of adjacent inner rings of circumferential reinforcement in a cage does not exceed 4 inches (102 mm) for pipe up to and including pipe having a 4 inches (102 mm) wall thickness or exceed wall thicknesses for larger pipe and in no case exceed 6 inches (152 mm).

2. Ensure that each line of S-stirrups have a continuous “S” shape extending longitudinally from end to end of the pipe. Ensure that they extend from the inner cage toward the outer surface of the pipe for a distance not less than the minimum amplitude. Ensure that S-stirrups pass around and are in contact with each inside circumferential member of the inner cage. Ensure that each line of S-stirrups lie essentially in a plane passing through the longitudinal axis of the pipe.

3. Where more than one length of stirrup

material is used per line, make a lap round one circumferential member of the

inner cage. Ensure that the ends of “S”

shaped stirrups at splices include an outer bend. Do not use more than three lengths of “S”

material in a line and ensure that the minimum length of a section of

S-stirrups is 30 inches (0.76 m).

3. Where more than one length of stirrup

material is used per line, make a lap round one circumferential member of the

inner cage. Ensure that the ends of “S”

shaped stirrups at splices include an outer bend. Do not use more than three lengths of “S”

material in a line and ensure that the minimum length of a section of

S-stirrups is 30 inches (0.76 m).

Illustrative Example of

S-Stirrup Support System for 0.01-inch Crack D-load 3000, 102-inch diameter

Pipe Minimum Area

Per Support 0.053 square inch, 11 Lines Spaced @ 5 1/8 inches. For other classes and sizes, see Tables

706.02-2, 3, and 4.

Illustrative Example of S-Stirrup Support

System for 0.3 mm Crack D-Load 140.0, 2550 mm diameter Pipe Minimum Area

per Support 34 mm2, 11 Lines Spaced @ 128 mm. For other classes and sizes, see Tables

706.02-2M, 3M, and 4M.

|

0.01-inch Crack D-Load 1000 Ultimate Strength D-Load 1500 |

|||

|

Internal Diameter of Pipe (in) |

Wall Thickness (in) |

Circular Reinforcement in Circular Pipe |

|

|

Inner Cage (in2/ft of pipe) |

Outer Cage (in2/ft of pipe) |

||

|

Reinforcing Steel 709.11 or 709.12 Only Concrete Strength 4000 psi |

|||

|

36 |

4 |

0.09 |

0.07 |

|

42 |

4 1/2 |

0.11 |

0.08 |

|

48 |

5 |

0.13 |

0.09 |

|

54 |

5 1/2 |

0.16 |

0.12 |

|

60 |

6 |

0.19 |

0.14 |

|

66 |

6 1/2 |

0.21 |

0.16 |

|

72 |

7 |

0.23 |

0.17 |

|

78 |

7 1/2 |

0.25 |

0.19 |

|

84 |

8 |

0.29 |

0.21 |

|

90 |

8 |

0.33 |

0.24 |

|

96 |

8 1/2 |

0.37 |

0.26 |

|

Concrete Strength 5000 psi |

|||

|

102 |

8 1/2 |

0.41 |

0.28 |

|

108 |

9 |

0.47 |

0.3 |

|

All Permitted Reinforcing Steel Concrete Strength 5000 psi |

|||

|

114 |

9 1/2 |

0.56 |

0.42 |

|

120 |

10 |

0.61 |

0.46 |

|

126 |

10 1/2 |

0.65 |

0.49 |

|

132 |

11 |

0.7 |

0.52 |

|

144 |

12 |

0.8 |

0.6 |

|

0.3 mm Crack D-Load 50.0 Ultimate Strength D-Load 75.0 |

|||

|

Internal Diameter of Pipe (mm) |

Wall Thickness (mm) |

Circular Reinforcement in Circular Pipe |

|

|

Inner Cage (cm2/m of pipe) |

Outer Cage (cm2/m of pipe) |

||

|

Reinforcing Steel 709.11 or 709.12 Only Concrete Strength 27.6 MPa |

|||

|

900 |

100 |

1.9 |

1.5 |

|

1050 |

113 |

2.3 |

1.7 |

|

1200 |

125 |

2.8 |

1.9 |

|

1350 |

138 |

3.4 |

2.5 |

|

1500 |

150 |

4 |

3 |

|

1650 |

163 |

4.4 |

3.4 |

|

1800 |

175 |

4.9 |

3.6 |

|

1950 |

188 |

5.3 |

4 |

|

2100 |

200 |

6.1 |

4.4 |

|

2250 |

200 |

7 |

5.1 |

|

2400 |

213 |

7.8 |

5.5 |

|

Concrete Strength 34.5 MPa |

|||

|

2550 |

213 |

8.7 |

5.9 |

|

2700 |

225 |

9.9 |

6.4 |

|

All Permitted Reinforcing Steel Concrete Strength 34.5 MPa |

|||

|

2850 |

238 |

11.9 |

8.9 |

|

3000 |

250 |

12.9 |

9.7 |

|

3150 |

263 |

13.8 |

10.4 |

|

3300 |

275 |

14.8 |

11 |

|

3600 |

300 |

16.9 |

12.7 |

4.1.1 In addition, test the pipe designs covered by Tables 706.02-1, 706.02-2, 706.02-3, and 706.02-4 and ASTM C 76 (ASTM C 76M), Tables 2 through 5, and interpolated designs by the three-edge bearing method. When the test load on the pipe reaches 115 percent of the required 0.01-inch (0.3 mm) crack D-load without developing a 0.01-inch (0.3 mm) or larger crack, accept the test specimen for strength. If any test specimen fails to pass this test, but attained the 0.01-inch (0.3 mm) crack, continue the test until the ultimate D-load is reached.

4.1.2 In addition, accept pipe 54 inches (1350 mm) and larger in diameter covered by Tables 706.02-1, 706.02-2, 706.02-3, and 706.02-4, and ASTM C 76 (ASTM C 76M), Tables 2 through 5, and interpolated designs according to Section 12 and the following requirements:

1. When pipe from a plant has been approved by the Laboratory for a specified design and pipe from the same plant has wall and steel area not less than the approved pipe.

2. When it has been established that two or more plants have complied with the above requirements for the class and size under consideration, and the plant under consideration has established compliance with the above requirements for an adjacent size, and the wall and steel area are not less than the pipe tested at the two plants.

6.1.2.1 Provide cement according to 701.

6.1.2.2 Provide fly ash according to 701.13

6.1.3 Provide aggregates conforming to the quality requirements of 703.02.

6.1.5 Provide steel according to 709.08, 709.10, 709.11, or 709.12.

6.2.4 Ensure that no more than two holes are cast, drilled, or otherwise neatly made in the shell of each piece of pipe for the purpose of handling or laying. Ensure that the holes are tapered unless drilled, and before backfilling, fill the tapered holes with portland cement mortar, or secure precast concrete plugs with portland cement mortar. Fill drilled holes with portland cement mortar.

7.1 and 7.3 In addition, perform strength tests using methods described in ASTM C 497 (ASTM C 497M).

10.1 In addition, ensure that pipe designs covered by Tables 706.02-1, 706.02-2, 706.02-3, and 706.02-4 and ASTM C 76 (ASTM C 76M) Tables 2 through 5 have the number of samples selected as shown in the “Minimum Requirements for Sampling Materials” table for each size, class, and production lot (pipe of the same size and class made from the same materials and by the same process and approximately the same production date) for test.

|

||||||||||||

|

0.01-inch Crack D-Load 1350 Ultimate Strength D-Load 2000 |

|

|||||||||||

|

Internal Diameter of Pipe (in) |

Wall Thickness (in) |

Circular Reinforcement in Circular Pipe |

S-Stirrups |

|

||||||||

|

Minimum Area Per Support Element (in2) |

Number of Lines[1] |

Longitudinal Spacing (in) |

Circumferential Spacing on Inner Cage (in) |

Minimum Amplitude[2] of Stirrups (in) |

||||||||

|

Inner Cage (in2/ft of pipe) |

Outer Cage (in2/ft of pipe) |

|||||||||||

|

Reinforcing Steel 709.11 or 709.12 Only Concrete Strength 4000 psi |

|

|||||||||||

|

36 |

4 |

0.12 |

0.09 |

|

|

|

|

|

|

|||

|

42 |

4 1/2 |

0.15 |

0.11 |

|

|

|

|

|

|

|||

|

48 |

5 |

0.17 |

0.12 |

|

|

|

|

|

|

|||

|

54 |

5 1/2 |

0.21 |

0.16 |

|

|

|

|

|

|

|||

|

60 |

6 |

0.26 |

0.20 |

|

|

|

|

|

|

|||

|

66 |

6 1/2 |

0.30 |

0.21 |

|

|

|

|

|

|

|||

|

72 |

7 |

0.35 |

0.24 |

|

|

|

|

|

|

|||

|

78 |

7 1/2 |

0.40 |

0.27 |

|

|

|

|

|

|

|||

|

84 |

8 |

0.47 |

0.30 |

|

|

|

|

|

|

|||

|

Concrete Strength 5000 psi |

|

|||||||||||

|

90 |

8 |

0.64 |

0.35 |

|

|

|

|

|

|

|||

|

96 |

8 1/2 |

0.80 |

0.40 |

|

|

|

|

|

|

|||

|

102 |

8 1/2 |

0.96 |

0.44 |

|

|

|

|

|

|

|||

|

108 |

9 |

1.07 |

0.47 |

|

|

|

|

|

|

|||

|

All Permitted Reinforcing Steel |

|

|||||||||||

|

114 |

9 1/2 |

0.69 |

0.52 |

0.041 |

5 |

2 |

6 1/8 |

6 5/8 |

|

|||

|

120 |

10 |

0.74 |

0.55 |

0.041 |

5 |

2 |

6 1/2 |

7 1/8 |

|

|||

|

126 |

10 1/2 |

0.79 |

0.60 |

0.041 |

5 |

2 |

6 7/8 |

7 5/8 |

|

|||

|

132 |

11 |

0.85 |

0.64 |

0.041 |

5 |

2 |

7 1/4 |

8 1/8 |

|

|||

|

144 |

12 |

0.97 |

0.73 |

0.041 |

5 |

2 |

8 |

9 1/8 |

|

|||

|

[1] Number

of lines in the table indicates the number of longitudinal lines required in

each top and bottom portion of the pipe.

The area of each support element in a pipe is two times the cross-sectional

area of the S-stirrups wire used.

There shall be an equal number of these lines of S-stirrups on either

side of the mid-point of both the top and bottom of the pipe. See Figure 1. |

|

|||||||||||

|

[2] The

amplitude is the overall width of the line of stirrups. |

|

|||||||||||

|

||||||||||||

|

0.3 mm Crack D-Load 65.0 Ultimate Strength D-Load 100.0 |

|

||||||||

|

Internal Diameter of Pipe (mm) |

Wall Thickness (mm) |

Circular Reinforcement in Circular Pipe |

S-Stirrups |

|

|||||

|

Minimum Area Per Support Element (mm2) |

Number of Lines[1] |

Longitudinal Spacing (mm) |

Circumferential Spacing on Inner Cage (mm) |

Minimum Amplitude[2] of Stirrups (mm) |

|||||

|

Inner Cage (cm2/m of pipe) |

Outer Cage (cm2/m of pipe) |

||||||||

|

Reinforcing Steel 709.11 or 709.12 Only Concrete Strength 27.6 MPa |

|

||||||||

|

900 |

100 |

2.5 |

1.9 |

|

|

|

|

|

|

|

1050 |

113 |

3.2 |

2.3 |

|

|

|

|

|

|

|

1200 |

125 |

3.6 |

2.5 |

|

|

|

|

|

|

|

1350 |

138 |

4.4 |

3.4 |

|

|

|

|

|

|

|

1500 |

150 |

5.5 |

4.2 |

|

|

|

|

|

|

|

1650 |

163 |

6.4 |

4.4 |

|

|

|

|

|

|

|

1800 |

175 |

7.4 |

5.1 |

|

|

|

|

|

|

|

1950 |

188 |

8.5 |

5.7 |

|

|

|

|

|

|

|

2100 |

200 |

9.9 |

6.4 |

|

|

|

|

|

|

|

Concrete Strength 34.5 MPa |

|

||||||||

|

2250 |

200 |

13.5 |

7.4 |

|

|

|

|

|

|

|

2400 |

213 |

16.9 |

8.5 |

|

|

|

|

|

|

|

2550 |

213 |

20.3 |

9.3 |

|

|

|

|

|

|

|

2700 |

225 |

22.6 |

9.9 |

|

|

|

|

|

|

|

All Permitted Reinforcing Steel |

|

||||||||

|

2850 |

238 |

14.6 |

11.0 |

26 |

5 |

50 |

156 |

168 |

|

|

3000 |

250 |

15.7 |

11.6 |

26 |

5 |

50 |

165 |

181 |

|

|

3150 |

263 |

16.7 |

12.7 |

26 |

5 |

50 |

175 |

194 |

|

|

3300 |

275 |

18.0 |

13.5 |

26 |

5 |

50 |

184 |

206 |

|

|

3600 |

300 |

20.5 |

15.5 |

26 |

5 |

50 |

203 |

232 |

|

|

[1] Number of lines in the table indicates the number of longitudinal lines required in each top and bottom portion of the pipe. The area of each support element in a pipe is two times the cross-sectional area of the S-stirrups wire used. There shall be an equal number of these lines of S-stirrups on either side of the mid-point of both the top and bottom of the pipe. See Figure 1M. |

|

||||||||

|

[2] The amplitude is the overall width of the line of stirrups. |

|

||||||||

|

|||||||||

|

0.01-inch Crack D-Load 2000 Ultimate Strength D-Load 3000 Concrete Strength 5000 psi |

|

||||||||

|

Internal Diameter of Pipe (in) |

Wall Thickness (in) |

Circular Reinforcement in Circular Pipe |

S-Stirrups |

|

|||||

|

Minimum Area Per Support Element (in2) |

Number of Lines[1] |

Longitudinal Spacing (in) |

Circumferential Spacing on Inner Cage (in) |

Minimum Amplitude[2] of Stirrups (in) |

|||||

|

Inner Cage (in2/ft of pipe) |

Outer Cage (in2/ft of pipe) |

||||||||

|

78 |

7 1/2 |

0.69 |

0.52 |

0.029 |

11 |

2 |

4 1/8 |

4 5/8 |

|

|

84 |

8 |

0.74 |

0.56 |

0.029 |

11 |

2 |

4 5/8 |

5 1/8 |

|

|

90 |

8 |

0.85 |

0.63 |

0.031 |

11 |

2 |

4 5/8 |

5 1/8 |

|

|

96 |

8 1/2 |

0.91 |

0.69 |

0.034 |

11 |

2 |

5 1/8 |

5 5/8 |

|

|

102 |

8 1/2 |

1.02 |

0.77 |

0.041 |

12 |

2 |

5 1/8 |

5 5/8 |

|

|

108 |

9 |

1.07 |

0.80 |

0.045 |

11 |

2 |

5 5/8 |

6 1/8 |

|

|

114 |

9 1/2 |

1.02 |

0.77 |

0.048 |

11 |

2 |

6 1/8 |

6 5/8 |

|

|

120 |

10 |

1.10 |

0.82 |

0.051 |

11 |

2 |

6 1/2 |

7 1/8 |

|

|

126 |

10 1/2 |

1.17 |

0.88 |

0.055 |

11 |

2 |

6 7/8 |

7 5/8 |

|

|

132 |

11 |

1.25 |

0.94 |

0.058 |

11 |

2 |

7 1/4 |

8 1/8 |

|

|

144 |

12 |

1.42 |

1.07 |

0.065 |

11 |

2 |

8 |

9 1/8 |

|

|

[1] Refer to Footnote for Table 706.02-2. |

|

||||||||

|

[2] Refer to Footnote for Table 706.02-2. |

|

||||||||

|

|||||||||

|

0.3 mm Crack D-Load 100 Ultimate Strength D-Load 150 Concrete Strength 34.5 MPa |

|

||||||||

|

Internal Diameter of Pipe (mm) |

Wall Thickness (mm) |

Circular Reinforcement in Circular Pipe |

S-Stirrups |

|

|||||

|

Minimum Area Per Support Element (mm2) |

Number of Lines[1] |

Longitudinal Spacing (mm) |

Circumferential Spacing on Inner Cage (mm) |

Minimum Amplitude[2] of Stirrups (mm) |

|||||

|

Inner Cage (cm2/m of pipe) |

Outer Cage (cm2/m of pipe) |

||||||||

|

1950 |

188 |

14.6 |

11.0 |

19 |

11 |

50 |

105 |

117 |

|

|

2100 |

200 |

15.7 |

11.9 |

19 |

11 |

50 |

117 |

130 |

|

|

2250 |

200 |

18.0 |

13.3 |

20 |

11 |

50 |

117 |

130 |

|

|

2400 |

213 |

19.3 |

14.6 |

22 |

11 |

50 |

130 |

143 |

|

|

2550 |

213 |

21.6 |

16.3 |

26 |

12 |

50 |

130 |

143 |

|

|

2700 |

225 |

22.6 |

16.9 |

29 |

11 |

50 |

143 |

156 |

|

|

2850 |

238 |

21.6 |

16.3 |

31 |

11 |

50 |

156 |

168 |

|

|

3000 |

250 |

22.3 |

17.4 |

33 |

11 |

50 |

165 |

181 |

|

|

3150 |

263 |

24.8 |

18.6 |

35 |

11 |

50 |

175 |

194 |

|

|

3300 |

275 |

26.5 |

19.9 |

37 |

11 |

50 |

184 |

206 |

|

|

3600 |

300 |

30.1 |

22.6 |

42 |

11 |

50 |

203 |

232 |

|

|

[1] Refer to Footnote for Table 706.02-2M. |

|||||||||

|

[2] Refer to Footnote for Table 706.02-2M. |

|||||||||

|

|||||||||

|

0.01-inch Crack D-Load 3000 Ultimate Strength D-Load 3750 |

|

||||||||

|

Internal Diameter of Pipe (in) |

Wall Thickness (in) |

Circular Reinforcement in Circular Pipe |

S-Stirrups |

|

|||||

|

Minimum Area Per Support Element (in2) |

Number of Lines[1] |

Longitudinal Spacing (in) |

Circumferential Spacing on Inner Cage (in) |

Minimum Amplitude[2] of Stirrups (in) |

|||||

|

Inner Cage (in2/ft of pipe) |

Outer Cage (in2/ft of pipe) |

||||||||

|

Concrete Strength 6000 psi |

|

||||||||

|

6 |

1 3/4 |

0.07 |

-- |

|

|

|

|

|

|

|

8 |

1 3/4 |

0.07 |

-- |

|

|

|

|

|

|

|

10 |

1 3/4 |

0.07 |

-- |

|

|

|

|

|

|

|

54 |

5 1/2 |

0.86 |

0.62 |

|

|

|

|

|

|

|

60 |

6 |

0.95 |

0.68 |

|

|

|

|

|

|

|

Concrete Strength 5000 psi |

|

||||||||

|

54 |

5 1/2 |

0.64 |

0.48 |

0.029 |

15 |

2 |

2 1/8 |

2 5/8 |

|

|

60 |

6 |

0.70 |

0.53 |

0.029 |

14 |

2 |

2 5/8 |

3 1/8 |

|

|

66 |

6 1/2 |

0.79 |

0.59 |

0.029 |

13 |

2 |

3 1/8 |

3 5/8 |

|

|

72 |

7 |

0.87 |

0.66 |

0.029 |

12 |

2 |

3 5/8 |

4 1/8 |

|

|

78 |

7 1/2 |

0.92 |

0.69 |

0.031 |

11 |

2 |

4 1/8 |

4 5/8 |

|

|

84 |

8 |

0.99 |

0.74 |

0.034 |

11 |

2 |

4 5/8 |

5 1/8 |

|

|

90 |

8 |

1.13 |

0.85 |

0.041 |

11 |

2 |

4 5/8 |

5 1/8 |

|

|

96 |

8 1/2 |

1.20 |

0.90 |

0.045 |

11 |

2 |

5 1/8 |

5 5/8 |

|

|

102 |

8 1/2 |

1.34 |

1.00 |

0.053 |

11 |

2 |

5 1/8 |

5 5/8 |

|

|

108 |

9 |

1.51 |

1.13 |

0.063 |

11 |

2 |

5 5/8 |

6 1/8 |

|

|

114 |

9 1/2 |

1.51 |

1.13 |

0.064 |

11 |

2 |

6 1/8 |

6 5/8 |

|

|

120 |

10 |

1.62 |

1.21 |

0.068 |

11 |

2 |

6 1/2 |

7 1/8 |

|

|

126 |

10 1/2 |

1.73 |

1.30 |

0.072 |

11 |

2 |

6 7/8 |

7 5/8 |

|

|

132 |

11 |

1.84 |

1.38 |

0.076 |

11 |

2 |

7 1/4 |

8 1/8 |

|

|

144 |

12 |

2.09 |

1.57 |

0.085 |

11 |

2 |

8 |

9 1/8 |

|

|

[1] Refer to Footnote for Table 706.02-2. |

|

||||||||

|

[2] Refer to Footnote for Table 706.02-2. |

|

||||||||

|

||||||||||||||||

|

0.3 mm Crack D-Load 140.0 Ultimate Strength D-Load 175.0 |

|

|||||||||||||||

|

Internal Diameter of Pipe mm |

Wall Thickness mm |

Circular Reinforcement in Circular Pipe |

S-Stirrups |

|

||||||||||||

|

Minimum Area Per Support Element (mm2) |

Number of Lines[1] |

Longitudinal Spacing (mm) |

Circumferential Spacing on Inner Cage (mm) |

Minimum Amplitude[2] of Stirrups (mm) |

||||||||||||

|

Inner Cage (cm2/m of pipe) |

Outer Cage (cm2/m of pipe) |

|||||||||||||||

|

Concrete Strength 41.4 MPa |

|

|||||||||||||||

|

150 |

44 |

1.5 |

-- |

|

|

|

|

|

|

|||||||

|

200 |

44 |

1.5 |

-- |

|

|

|

|

|

|

|||||||

|

250 |

44 |

1.5 |

-- |

|

|

|

|

|

|

|||||||

|

1350 |

138 |

18.2 |

13.1 |

|

|

|

|

|

|

|||||||

|

1500 |

150 |

20.1 |

14.4 |

|

|

|

|

|

|

|||||||

|

Concrete Strength 34.5 MPa |

|

|||||||||||||||

|

1350 |

138 |

13.5 |

10.2 |

19 |

15 |

50 |

54 |

67 |

|

|||||||

|

1500 |

150 |

14.8 |

11.2 |

19 |

14 |

50 |

37 |

79 |

|

|||||||

|

1650 |

163 |

16.7 |

12.5 |

19 |

13 |

50 |

79 |

92 |

|

|||||||

|

1800 |

175 |

18.4 |

14.0 |

19 |

12 |

50 |

92 |

105 |

|

|||||||

|

1950 |

188 |

19.5 |

14.6 |

20 |

11 |

50 |

105 |

117 |

|

|||||||

|

2100 |

200 |

21.0 |

15.7 |

22 |

11 |

50 |

117 |

130 |

|

|||||||

|

2250 |

200 |

23.9 |

18.0 |

26 |

11 |

50 |

117 |

130 |

|

|||||||

|

2400 |

213 |

25.4 |

19.1 |

29 |

11 |

50 |

130 |

143 |

|

|||||||

|

2550 |

213 |

28.4 |

21.2 |

34 |

11 |

50 |

130 |

143 |

|

|||||||

|

2700 |

225 |

32.0 |

23.9 |

41 |

11 |

50 |

143 |

156 |

|

|||||||

|

2850 |

238 |

32.0 |

23.9 |

41 |

11 |

50 |

156 |

168 |

|

|||||||

|

3000 |

250 |

34.3 |

25.6 |

44 |

11 |

50 |

165 |

181 |

|

|||||||

|

3150 |

263 |

36.6 |

27.5 |

46 |

11 |

50 |

175 |

194 |

|

|||||||

|

3200 |

275 |

38.9 |

29.2 |

49 |

11 |

50 |

184 |

206 |

|

|||||||

|

3600 |

300 |

44.2 |

33.2 |

55 |

11 |

50 |

203 |

232 |

|

|||||||

|

[1] Refer to Footnote for Table 706.02-2M. |

|

|||||||||||||||

|

[2] Refer to Footnote for Table 706.02-2M. |

|

|||||||||||||||

|

||||||||||||||||

11.1 Perform

compression tests on cores according to ASTM C

497 (ASTM C

497M).

11.3 Does not apply.

12 Perform inspection at the project site. Obtain random samples from material delivered

to the project site or at other locations designated by the Laboratory.

16 Furnish materials from suppliers certified according to Supplement 1074.

17 In addition, after the capital letter “D,”

designate the D-load, the design wall thickness in millimeters (inches

expressed as a decimal). Ensure that

pipe with S-stirrups have the symbol “S”.

Ensure that pipe requiring axis orientation without lift holes (i.e.,

stirrup pipe, quadrant reinforced pipe, elliptically reinforced pipe) has the

centerline of the crown of the pipe marked inside and outside with the symbol

“TB”. Mark pipe with quadrant steel with

the symbol “Q”. Mark pipe with

elliptical reinforcement with the symbol “E”.

Mark pipe with deformed wire reinforcement required in the design with

the symbol “DF”.

706.03 Reinforced

Concrete Pipe, Epoxy

Coated. Provide Type A reinforced concrete epoxy coated pipe conforming to 706.02 and Type B

conforming to 706.04,

with the following modification:

In the plant, prepare

the interior barrel and joint surface areas of the concrete pipe to remove all

forms of oil, laitance, and other deleterious materials and then line them with

a high-build, polyamide-cured, two-component coal tar epoxy coating, Military Specification DOD-P-23236A

(SH). Spray the lining compound to

obtain a continuous and relatively uniform and smooth lining with a minimum dry

film thickness of 0.03 inch (760 mm). Ensure that all coated pipe

are free of surface irregularities such as air bubbles, delamination, lumping,

sagging, blistering, pinholing, or porosity, in the coating film.

706.04 Reinforced Concrete Elliptical Culvert,

Storm Drain, and Sewer Pipe. Provide reinforced concrete elliptical culvert,

storm drain, and sewer pipe conforming to ASTM C

507 (ASTM C

507M), with the following modifications:

4.1 Delete Class HE-A. Table 706.04-1 includes additional design requirements.

5.1 All materials, processes of manufacture, and finished pipe are subject to inspection and approval by the Department. When directed by the Laboratory, the manufacturer will cut holes in sections of the finished pipe for inspection.

6.2.1 Provide cement according to 701, except 701.07.

6.2.2 Provide fly ash according to 701.

6.3 Provide aggregates conforming to the quality requirements of 703.02.

6.5 Provide steel according 709.08, 709.10, 709.11, or 709.12.

7.2 In addition, manufacture horizontal elliptical pipe HE-II and HE-III using the design requirements of Table 706.04-1.

8.1 In addition, ensure that pipe made in accordance with 706.04-1 has three lines of reinforcement of elliptical shape. Place the outer and inner lines of reinforcement so that the nominal protective covering of the concrete over the reinforcement in the barrel of the pipe is 1 inch (25 mm) subject to the variations permitted in Section 12.5. Ensure that the third or middle line is in contact with and fastened securely to the inner line at the vertical axis of the pipe both top and bottom and to the outer line at the horizontal axis on both sides. Ensure that the length of the middle line is the average of the length of the inner and outer line. Ensure that the middle line is of an elliptical shape and runs smoothly between the specified points of contact with the inner and outer lines.

10 Ensure that no more than two holes are cast, drilled, or otherwise neatly made in the shell of each piece of pipe for the purpose of handling or laying. Taper the holes unless drilled, and before backfilling, fill the tapered holes with portland cement mortar, or secure the precast concrete plugs with portland cement mortar. Fill the drilled holes with portland cement mortar.

11.2 Select the specified number of pipe, as noted in the “Minimum Requirements for Sampling Materials” table, for the purpose of test at the plant and at random from the lot to be shipped or at the project site from the pipe delivered and that are pipe that would not otherwise be rejected under these Specifications. Test pipe according to Section 5.1.1 except the Laboratory may accept pipe 54 inches (1350 mm) and larger in diameter according to Section 5.1.2 and the following requirements:

1. When pipe from a plant has been approved by the Laboratory for a specified design, pipe from the same plant with wall and steel area not less than the approved pipe may be approved by means of tests on cores verifying absorption, strength, wall, and steel area.

2. When it has been established that two or more plants have complied with the above requirements for the class and size under consideration and the plant under consideration has established compliance with the above requirements for an adjacent size, and the wall and steel area are not less than the pipe tested at the two plants.

11.3.1 Ensure that the load to produce a 0.01-inch (0.3 mm) crack and the ultimate load as determined by ASTM C 497 (ASTM C 497M) three-edge bearing method, is not less than shown in Tables 1, 2, and 706.04-1. The ultimate strength test may be waived when the test load on the pipe reaches 115 percent of the required 0.01-inch (0.3 mm) crack D-load without developing a 0.01-inch (0.3 mm) or larger crack.

11.4 Perform compression tests for satisfying the minimum specified concrete strength requirement from cores drilled from the wall of the pipe. Ensure that the diameter of the core is such that the capped height to diameter or L/D ratio lies between one and two. Ensure that the cores are secured, prepared for testing, and tested by methods prescribed in the appropriate sections of ASTM C 497 (ASTM C 497M). Ensure that the compressive strength of each core tested is equal to or greater than the design strength of the concrete. If a core does not meet the required strength, test another core from the same pipe. If this core does not meet the required strength, the Department may reject the pipe. Make additional tests on other pipe to determine the acceptability of the lot. When the cores cut from a section of pipe successfully meet the strength test requirement, ensure that the core holes are plugged and sealed by the manufacturer in a manner such that the pipe section will meet all of the test requirements of these Specifications.

11.9 Does not apply.

11.10 Does not apply.

14 Perform inspection at the project site. Obtain random samples from material delivered to the project site or at other locations designated by the laboratory.

Ensure manufacturers of these materials are certified according to Supplement 1074.

16 In addition, place the plant location on each pipe, and for pipe manufactured to design requirements of 706.04-1 place the letter “A” after the pipe class. Ensure that the markings are legible and indented in the pipe section or painted on with waterproof paint.

Table 706.04-1 Design Requirements for Horizontal Elliptical Pipe |

||||

|

Equivalent Round Size (in) |

Rise (in) ´ Span (in) |

Minimum Wall Thickness (in) |

Minimum Reinforcement (in2/ft) |

|

|

HE-II |

HE-III |

|||

|

D-Loads |

||||

|

0.01=1000 |

0.01 = 1350 |

|||

|

Utl. = 1500 |

Utl. = 2000 |

|||

|

78 |

63 ´ 98 |

8 |

3 lines totaling 0.87 |

3 lines totaling 1.23 |

|

84 |

68 ´ 106 |

8 1/2 |

3 lines totaling 0.97 |

3 lines totaling 1.33 |

|

90 |

72 ´ 113 |

9 |

3 lines totaling 1.03 |

3 lines totaling 1.43 |

|

96 |

77 ´ 121 |

9 1/2 |

3 lines totaling 1.13 |

3 lines totaling 1.54 |

|

102 |

82 ´ 128 |

9 3/4 |

3 lines totaling 1.23 |

3 lines totaling 1.70 |

|

108 |

87 ´ 136 |

10 |

3 lines totaling 1.43 |

3 lines totaling 1.85 |

|

The test load in lb/ft equals D-load x nominal inside span in feet. Concrete strength=5000 psi. |

||||

|

Table

706.04-1M Design Requirements for

Horizontal Elliptical Pipe |

||||

|

Equivalent Round Size (mm) |

Rise (mm) ´ Span (mm) |

Minimum Wall Thickness (mm) |

Minimum Reinforcement (cm2/m) |

|

|

HE-II |

HE-III |

|||

|

D-Loads |

||||

|

0.03 = 50.0 |

0.03=65.0 |

|||

|

Utl. = 75.0 |

Utl.=100.0 |

|||

|

1950 |

1585 ´ 2495 |

200 |

3 lines totaling 18.4 |

3 lines totaling 26.0 |

|

2100 |

1705 ´ 2690 |

213 |

3 lines totaling 20.5 |

3 lines totaling 28.2 |

|

2250 |

1830 ´ 2880 |

225 |

3 lines totaling 21.8 |

3 lines totaling 30.3 |

|

2400 |

1950 ´ 3070 |

238 |

3 lines totaling 23.9 |

3 lines totaling 32.6 |

|

2550 |

2075 ´ 3265 |

244 |

3 lines totaling 26.0 |

3 lines totaling 36.0 |

|

2700 |

2195 ´ 3455 |

250 |

3 lines totaling 30.3 |

3 lines totaling 39.2 |

|

The test load in kN/m equals D-load x nominal inside span in mm. Concrete strength=34.5 MPa. |

||||

706.05 Precast Reinforced Concrete Box Sections. Provide precast reinforced concrete box section conforming to ASTM C 1433 (ASTM C 1433M), with the following modifications:

Ensure that manufacturers of precast concrete members are certified by the Laboratory according to Supplement 1073.

6.2.1 Provide cement according to 701, except 701.07.

6.2.2 Provide fly ash according to 701.

6.3 Provide aggregates conforming to the quality requirements of 703.02.

6.5 Provide steel according to 709.10 or 709.12. Ensure that the longitudinal distribution reinforcement for box sections with less than 2 feet (0.6 m) of cover are subject to highway loadings in 709.01 according to ASTM A 615, Grade 60 (ASTM A 615M, Grade 400).

7.1 Only designs from Table 2 with the following sizes are permitted. The box sizes, span by rise, are 8 ´ 4, 5, 6, 7; 10 ´ 5, 6, 7, 8, 9; and 12 ´ 4, 6, 8, 10 feet (2400 ´ 1200, 1500, 1800, 2100; 3000 ´ 1500, 1800, 2100, 2400, 2700; and 3600 ´ 1200, 1800, 2400, 3000 mm).

9.1 Provide hardened concrete that contains a minimum of 4 percent entrained air for wet-cast sections with spans less than 14 feet (4200 mm) and for all sections with spans 14 feet (4200 mm) and greater.

9.4 Lift holes are not permitted. Use handling devices that do not require a hole through the box.

10.1 Verify concrete strength

using cylinders. Do not ship items

before the design strength of the concrete is reached.

11.5 A minimum cover of 1/2 inch (13 mm) over both circumferential and longitudinal reinforcement is required at the mating surfaces of joints.

15 In addition, mark the identification of the plant on each box section. For box sections 14 feet (4200 mm) or greater, mark the reinforcing steel areas for the section on each box section. Place the manufacturers’ name and required product information on the inside of the box section within the top one-half of the culvert.

706.051 Precast Reinforced Concrete Three-Sided Flat Topped Culverts. Provide precast concrete three-sided flat topped culverts according to ASTM C 1504, with the following modifications:

Provide flat deck culvert structures with a minimum clear span (measured normal to the structure at the bottom of the haunch) of 14 feet (4200 mm) and a minimum opening rise (measured from bottom of leg to bottom of deck at the centerline of the structure) of 4 feet (1200 mm); and a maximum clear span of 34 feet (10,200 mm) and maximum opening rising of 10 feet (3000 mm). Ensure that the minimum wall and deck thicknesses is 10 inches (250 mm) and 12 inches (300 mm) respectively, measured under the haunch normal to the structure and at the centerline of the span measured perpendicular to the structure.

Ensure manufacturers of precast concrete members are certified according to Supplement 1073.

Ensure that the manufacturer submits design calculations, a structural load rating and shop drawings for review and approval by the Department. Do not produce any units until receiving approval . Submit a minimum of seven copies of the drawings. Allow a minimum of four weeks for approval. Ensure that the shop drawings include the following:

1. All structural design according to section 900 of the Department’s bridge design manual and loading information.

2. Load rate the structure according to the requirements of section 900 of the Department’s bridge design manual.

3. All material specifications.

4. All plan view.

5. All elevation view.

6. All headwall and wingwall attachment requirements.

7. All dimensions.

8. All maintenance of traffic phases.

9. All section sizes.

10. All design handling strength.

The manufacturer may modify an approved shop drawing and resubmit for approval to the Department.

Ensure that the shop drawings also include the following special information as required:

1. For top mounted guardrail, show the guardrail plate and bolt locations in the plan view. Ensure that holes are a minimum of 6 inches (150 mm) from a joint.

2. For side mounted guardrail, show additional reinforcing details as per the plan details.

6.2.1 Provide cement according to 701, except 701.07.

6.2.2 Provide fly ash according to 701.13.

6.3 Provide aggregates conforming to the quality requirements of 703.02.

6.4 Use chemical admixtures according to 705.12. Use a corrosion inhibitor unless epoxy coated reinforcing steel is used. An approved list of corrosion inhibiting admixtures is on file at the Laboratory. Manufacturers should recognize that the corrosion inhibitors and admixtures may have an effect on strength, entrained air content, workability, etc. of their concrete mixes. The manufacturers choice of one of these corrosion inhibitors does not alleviate meeting all design requirements of this structure.

6.4.1 Provide air-entraining admixture according to 705.10.

6.5 Provide reinforcement consists of welded wire fabric according to 709.10 or 709.12, or deformed billet steel bars according to CMS 709.01, Grade 60 (Grade 420). Provide epoxy coated reinforcement according to 709.00 or 709.14. In lieu of epoxy coated reinforcement, use a corrosion inhibiting concrete admixture. Reinforcement from a precast structure into a cast-in-place structure, which does not contain a corrosion inhibitor admixture, will be epoxy coated according to 709.00 or 709.14.

7.1 Ensure that all designs for concrete compressive strengths greater than 5000 pounds per square inch (35 MPa) include, with the shop drawings, the mix design and a history of successful use of the mix design.

Where circumferential (main) reinforcement is composed of bars, check crack control criteria using the following: Z = 150 inside face (interior surface) and Z = 130 outside face (exterior surface).

7.2 Ensure that the concrete cover dimension over reinforcement is a minimum of 2 inches (50 mm) in the slab and in the exterior of the leg. Ensure that the interior of the leg reinforcement cover tapers from 1 inch (25 mm) at the bottom of the leg to 2 inches (50 mm) at the bottom of the haunch.

Ensure that the ends of longitudinal reinforcement have a minimum cover of 1/2 inch (13 mm), and spacers used to position the reinforcement are plastic or epoxy coated steel regardless of whether a corrosion inhibiting admixture is used.

8 Ensure that the top slab is produced with a keyway joint. The keyway provides a void volume equivalent to that of 12 inches (300 mm) prestressed beam as per Standard Construction Drawing PSBD-1-93. Ensure that the joint in the leg sections is designed to produce a shear key or inter-locking joint. Ensure that non-adjoining outside legs are flat. Sandblast the joint surfaces to the satisfaction of the Department, or a 2000 pounds per square inch (14 MPa) water blast no more than 14 days prior to shipping. Ensure that the culvert is designed such that the sections when laid together will make a continuous line with a smooth interior free of appreciable irregularities, all compatible with the permissible variations of Section 11.

9 Application of membrane waterproofing at any location other than the final location shown on the plans is prohibited.

9.1 Ensure that the aggregate, cement, and water are manufactured in conformance with 499.06, 499.07, and 499.09.

Ensure that the temperature requirements of 511.08 and 511.15 are met.

Ensure that the proportion of portland cement is not less than 564 pounds per cubic yard (335 kg/m3) of concrete.

If used, add the corrosion inhibitor as an aqueous solution. Consider the water in the solution as mixing water for the purpose of determining the w/c ratio of concrete.

9.2 Cure the three-sided sections in the forms for the length of time required to obtain the specified minimum design handling strength as defined in the shop drawings. Test a cylinder to check each section’s design handling strength. Repeat this test as often as needed. Only one cylinder passing will ensure that the design handling strength has been met. If the shop drawing shows no design handling strengths, then the minimum handling strength is assumed to be 100 percent of the design strength. Ensure that the curing then continues either in or out of the forms until the specified minimum design strength is met.

9.2.1 Steam curing is an accelerated cure by low pressure steam or radiant heat within a suitable insulated enclosure to contain the live steam or heat. The initial application of the steam or heat is from two to four hours after the final placement of concrete to allow the initial set to take place. If retarders are used, increase the waiting period to 4 to 6 hours. As an alternative, determine the actual time of initial set according to ASTM C 403. Do not start curing until the actual time to initial set has elapsed.

During the waiting period, ensure that the temperature within the curing enclosure is not less than 50 °F (10 °C).

During the initial application of live steam or radiant heat, ensure that the ambient temperature within the curing enclosure increases at an average rate not exceeding 40 °F (22 °C) per hour until the curing temperature is reached.

Ensure that the maximum curing temperature does not exceed 150 °F (65 °C). Hold the design temperature until the concrete has reached the desired design strength. Do not direct the application of live steam on the concrete forms so as to cause localized high temperatures.

9.2.2 Provide water curing according to 511.15 and 511.17, Method A.

9.2.3 Provide membrane curing according to 511.16, Method B.

9.3 Ensure that all forms are in place until the design handling strength is met.

9.4 Holes for handling or setting are not permitted. Do not move members before the design handling strength of the concrete is reached, or shipped before the design strength of the concrete is reached. Ensure that the manufacturers have equipment necessary to handle and transport the pieces without damaging them.

10 Ensure that the hardened concrete contains a minimum of 4 percent entrained air.

10.2.1 Keep the cylinders and matching culvert section together to guarantee the cylinders are matched with the corresponding culvert section; or, upon agreement by the Department, keep the cylinders at a location that will provide the same environment as the culvert sections.

10.2.2 For each section of the culvert, produce and mark at least four cylinders so that they are identifiable with the matching culvert section.

10.2.3 Conform to Supplement 1073 for acceptance.

10.2.3.1 Ensure that cylinder strengths conform to Supplement 1073.

10.3.3.2 Deleted.

10.4 Plug the core holes by using a concrete that is the same as that used in the section and cured in according to Section 9.2, or by a non-shrink grout that exceeds the concrete design strength.

11 The design in the plan reflects the external top slab elevation of the structure. If the structure supplied has a deck thicker than the plan design, eliminate the difference between the design top slab elevation and the supplied top slab elevation by a reducing the leg length. The Department may approve alternate methods to eliminate the difference between the design top slab elevation and the supplied top slab elevation. The Department will not approve a change in the top slab elevation from that shown on the plans.

The clear span shown is the minimum for the structure. The manufacturer may provide a clear span greater than that shown. Base the exact footer locations for both the elevation and offset on the manufacturer’s shop drawings. Ensure that these footer locations are such that the centerline of the leg at the bottom of the haunch matches the centerline of the footer.

All changes to the project resulting from the manufacturer’s dimensional changes in the structure are at no charge to the Department.

Ensure that the sections are free of fractures spalls and chips. Ensure that all surfaces have a smooth and regular finish being defined as a 1/4-inch variation within 4 feet (6 mm variation within 1.2 m).

11.1 Ensure that the slab and walls are perpendicular with a diagonal difference of not more than 0.5 percent.

Ensure that the length of each section is within 1/2 inch (13 mm) of the design length. Consider the length is the average of the length measured at each side and at the middle of the three-sided section.

11.4 Ensure that the maximum variation in the position of the reinforcement is 3/8 inch (9 mm), except that the cover over the reinforcement for the external surface of the top slab is not less than 2 inches (50 mm). The above tolerances or cover requirements do not apply to mating surfaces at the joint.

11.5 Resubmit any change in reinforcement from the shop drawings for approval.

12 Make repairs according to the Department’s requirements. The Department will not make additional payments for culvert repairs. Repairs are acceptable if, in the opinion of the Department, the repairs are sound, properly finished, and cured.

13 Perform inspection at the project site.

Furnish precast concrete components from suppliers certified according to Supplement 1073.

14 Form seams and slight surface irregularities that are expected from a wood panel forming system will not be cause for rejection. In addition, hairline cracks less than 0.01 inch (0.25 mm) are not cause for rejection.

15.1 Ensure that the location of the product marking is on the interior of the three-sided section 1 foot (300 mm) below the leg haunch.

Add the product marking upon removal of the forms.

The manufacturer may be required to repeat the product markings before the project is final.

706.052 Precast Reinforced Concrete Arch Sections. Provide precast reinforced concrete arch sections according to ASTM C 1504, with the following modifications:

This item shall consist of manufacturing precast reinforced concrete arch sections for culverts.

Ensure that manufacturers of precast concrete members are certified according to Supplement 1073.

5 Ensure the manufacturer submits design calculations, a structural load rating and shop drawings for review and approval by the Department. Do not produce any units until receiving approval. Submit a minimum of seven copies of the drawings. Allow a minimum of 4 weeks for approval. Ensure the shop drawings include the following:

1. All structural design according to section 900 of the Department’s bridge design manual and loading information.

2. Load rate the structure according to the requirements of section 900 of the Department’s bridge design manual.

3. All material specifications.

4. All plan view.

5. All elevation view.

6. All headwall and wingwall attachment requirements.

7. All dimensions.

8. All maintenance of traffic phases.

9. All section sizes.

10. All design handling strength.

The manufacturer may modify an approved shop drawing and resubmit for approval to the Department.

Ensure that the shop drawings also include the following special information as required:

1. For top mounted guardrail, the guardrail plate and bolt locations are shown in the plan view. Holes shall be a minimum of 6 inches (150 mm) from a joint.

2. For side mounted guardrail, additional reinforcing details are shown as per the plan details.

6.2.1 Provide cement according to 701, except 701.07.

6.2.2 Provide fly ash according to 701.13.

6.3 Provide aggregates conforming to the quality requirements of 703.02.

6.4 Use chemical admixtures according to 705.12. Use a corrosion inhibitor unless epoxy coated reinforcing steel is used. An approved list of corrosion inhibiting admixtures is on file at the Laboratory. Manufacturers should recognize that the corrosion inhibitors and admixtures may have an effect on strength, entrained air content, workability, etc. of their concrete mixes. The manufacturers choice of one of these corrosion inhibitors does not alleviate meeting all design requirements of this structure.

6.4.1 Provide air-entraining admixture according to 705.10.

6.5 Provide reinforcement consists of welded wire fabric according to 709.10 or 709.12, or deformed billet steel bars according to CMS 709.01, Grade 60 (Grade 420). Provide epoxy-coated reinforcement according to 709.00 or 709.14. Instead of epoxy coated reinforcement, use a corrosion inhibiting concrete admixture. Reinforcement from the precast structure into a cast-in-place structure, which does not contain a corrosion inhibitor admixture, will be epoxy coated according to 709.00 or 709.14.

7.1 Ensure that concrete compressive strength are greater than 4000 pounds per square inch (28 MPa).

7.2 Ensure

that the concrete cover dimension over the

outside circumferential reinforcement is a minimum of 2 inches (50 mm). Ensure that the concrete cover dimension over

the inside circumferential reinforcement is a minimum of 1 1/2 inches (38

mm). The clear distance of the end

circumferential wires shall not be less than 1 inch (25 mm) nor more than 2

inches (50 mm) from the ends of the sections.

Reinforcement shall be assembled utilizing single or multiple layers of

welded wire fabric (three-layer maximum), or utilizing a single layer of

deformed billet-steel bars. The welded

wire fabric shall be composed of circumferential and longitudinal wires and

shall contain sufficient longitudinal wires extending through the section to

maintain the shape and position of reinforcement. Longitudinal distribution reinforcement may

be welded wire fabric or deformed billet-steel bars. The ends of the longitudinal distribution

reinforcement shall be not more than 3 inches (75 mm) from the ends of the

sections.

The outside and inside circumferential

reinforcing steel for the corners of the culvert shall be bent to such an angle

that it is approximately equal to the configuration of the culverts outside

corner.

7.3 Tension splices in the circumferential reinforcement

shall not be made. For splices other

than tension splices, the overlap shall be a minimum of 12 inches (300 mm) for

welded wire fabric or deformed billet steel bars. The spacing center-to-center of the

circumferential wires in a wire fabric sheet shall be not less than 2 inches

(50 mm) or more than 4 inches (100 mm).

For the wire fabric, the spacing center-to-center of the longitudinal

wire shall not be more than 8 inches (200 mm).

The spacing center-to-center of the longitudinal distribution steel for

either line of reinforcing in the top slab shall be not more than 16 inches

(410 mm).

8.1 Ensure the sections are produced with

butt ends. The ends of the sections

shall be such that when the sections are laid together they will make a

continuous line of sections with a smooth interior free of appreciable irregularities,

all compatible with the permissible variations in these Specifications. Provide a chamfer on the outside surface at

the sections joint to form a void for a 7/8 ´ 1 3/8-inch (24 ´ 34

mm) flexible plastic gasket 706.14.

9 Application of membrane waterproofing on the arch section at any location other than the final location shown on the plans is prohibited.

9.1 Ensure that the aggregate, cement, and water are manufactured according to 499.06, 499.07, and 499.09.

Ensure that the temperature requirements of 511.08 and 511.15 are met.

Ensure that the proportion of portland cement is not less than 564 pounds per cubic yard (335 kg/m3) of concrete.

If used, add the corrosion inhibitor as an aqueous solution. Consider the water in the solution as mixing water for the purpose of determining the water-cement ratio of concrete.

9.2 Cure the arch sections in the forms for the length of time required to obtain the specified minimum design handling strength as defined in the shop drawings. Test a cylinder to check each section’s design handling strength. Repeat this test as often as needed. Only one cylinder passing will ensure that the design handling strength has been met. If the shop drawing shows no design handling strengths, then the minimum handling strength is assumed to be 100 percent of the design strength. Ensure that the curing then continues either in or out of the forms until the specified minimum design strength is met.

9.2.1 Steam curing is an accelerated cure by low pressure steam or radiant heat within a suitable insulated enclosure to contain the live steam or heat. The initial application of the steam or heat is from 2 to 4 hours after the final placement of concrete to allow the initial set to take place. If retarders are used, increase the waiting period to 4 to 6 hours. As an alternative, determine the actual time of initial set according to ASTM C 403. Do not start curing until the actual time to initial set has elapsed.

During the waiting period, ensure that the temperature within the curing enclosure is not less than 50 °F (10 °C).

During the initial application of live steam or radiant heat, ensure that the ambient temperature within the curing enclosure increases at an average rate not exceeding 40 °F (22 °C) per hour until the curing temperature is reached.

Ensure that the maximum curing temperature does not exceed 150 °F (65 °C). Hold the design temperature until the concrete has reached the desired design strength. Do not direct the application of live steam on the concrete forms so as to cause localized high temperatures.

9.2.2 Provide water curing according to 511.15 and 511.17, Method A.

9.2.3 Deleted.

9.3 Ensure that all forms are in place until the design handling strength is met.

Holes for handling or setting are not permitted. Do not move members before the design handling strength of the concrete is reached, or shipped before the design strength of the concrete is reached. Ensure that the manufacturers have equipment necessary to handle and transport the pieces without damaging them.

10 Ensure that the hardened concrete contains a minimum of 4 percent entrained air.

10.2.1 Keep the cylinders and matching culvert section together to guarantee the cylinders are matched with the corresponding culvert section; or, upon agreement by the Department, keep the cylinders at a location that will provide the same environment as the culvert sections.

10.2.2 For each section of the culvert, produce and mark at least four cylinders so that they are identifiable with the matching culvert section.

10.2.3 Conform to Supplement 1073 for acceptance.

10.2.3.1 Ensure that cylinder strengths conform to Supplement 1073.

10.3.3.2 Deleted

10.4 Plug the core holes by using a concrete that is the same as that used in the section and cured according to Section 9.2, or by a non-shrink grout that exceeds the concrete design strength.

11.0 The under-run in length of a section shall not be more than 1/2 inch (13 mm).

All changes to the project resulting from the manufacturer’s dimensional changes in the structure are at no charge to the Department.

Ensure that the sections are free of fractures spalls and chips. Ensure that all surfaces have a smooth and regular finish being defined as a 1/4 inch variation within 4 feet (6 mm variation within 1.2 m).

11.1 The internal dimensions shall vary not more than 1 percent from the design dimensions or more than 38 mm (1 1/2 inches), whichever is less. The haunch dimensions shall vary not more than 19 mm (3/4 inch) from the design dimension.

11.4 Ensure that the maximum variation in the position of the reinforcement is 3/8 inch (9 mm), except that the cover over the reinforcement for the external surface of the top slab is not less than 2 inches (50 mm). The above tolerances or cover requirements do not apply to mating surfaces at the joint.

11.5 Resubmit any change in reinforcement from the shop drawings for approval.

12.0 Make repairs according to the Department’s requirements. The Department will not make additional payments for culvert repairs. Repairs are acceptable if, in the opinion of the Department, the repairs are sound, properly finished, and cured.

13.0 Perform inspection at the project site.

Furnish precast concrete components from suppliers certified according to Supplement 1073.

14.0 Form seams and slight surface irregularities that are expected from a wood panel forming system will not be cause for rejection. In addition, hairline cracks less than 0.01 inch (0.25 mm) will not be cause for rejection.

15.1 Ensure that the location of the product marking is on the interior of the arch section 1 foot (300 mm) below the leg haunch.

Add the product marking upon removal of the forms.

The manufacturer may be required to repeat the product markings before the project is final.

706.06 Perforated Concrete Pipe. Provide perforated concrete pipe according to ASTM C 444 (ASTM C 444M), and 706.01 or 706.02.

Ensure manufacturers providing materials are certified according to Supplement 1074.

706.07 Concrete Drain Tile. Provide extra-quality concrete drain tile according to ASTM C 412 (ASTM C 412M), with the following modifications:

Ensure manufacturers providing materials are certified according to Supplement 1074.

4.0 This specification covers extra-quality concrete drain tile only.

5.1(3) Does not apply.

6.2.1 Provide cement according to 701, except 701.07.

6.2.2 Provide fly ash according to 701.13

6.3 Provide aggregate conforming to the quality requirements of 703.02.

8.1 Perform inspection at the project site. Obtain random samples from material delivered to the project site or at other locations designated by the Laboratory. Ensure manufacturers providing materials are certified according to Supplement 1074.

Testing. Ensure that the manufacturer furnishes all facilities and personnel to carry out the tests.

706.08 Vitrified Clay Pipe. Provide vitrified clay pipe according to ASTM C 700, with the following modifications:

Furnish materials according to the Department’s Qualified Products List (QPL).

14.0 Perform all tests except hydrostatic according to ASTM C 301.

15.0 Perform inspection at the project site. Obtain random samples from material delivered to the project site or at other locations designated by the Laboratory.

706.09 Clay Drain Tile. Provide extra-quality clay drain tile according to ASTM C 4, with the following modifications:

6.1 Perform inspection at the project site. Obtain random samples from material delivered to the project site or at other locations designated by the Laboratory.

11, 12, and 13 Ensure that the manufacturer furnishes all facilities and personnel to carry out the tests.

Furnish materials according to the Department’s Qualified Products List (QPL).

706.10 Bituminous Pipe Joint Filler. Provide cold applied, mineral filled, joint sealing compound for joints of bell and spigot, or tongue and groove sewer; or drain pipe conforming to the following:

A. Composition. Provide a steam-refined petroleum asphalt or a refined coal tar, dissolved in a suitable solvent, and containing an appropriate stiffener.

B. General Requirement. Provide a bituminous plastic cement that has a smooth, uniform mixture, not thickened or livered, and that shows a separation easily overcome by stirring. Ensure that the material is of such consistency and properties that it is readily applied with a trowel, a putty knife, or with a caulking gun without pulling or drawing. Provide a material that when applied to metal, concrete, or vitrified clay surfaces, exhibits good adhesive and cohesive properties and has only slight shrinkage after curing. Provide a material that is not damaged by exposure to below freezing temperatures.

C. Detail Requirements. Provide materials conforming to the following requirements:

|

1. |

When applied in a layer 1/16 to 1/8-inch (1.6 to 3.2 mm) thick on a tinned metal panel and cured at room temperature for 24 hours, the bituminous plastic cement shall set to a tough, plastic coating, free from blisters. |

||

|

|

|

Minimum |

Maximum |

|

2. |

Grease Cone Penetration (unworked, 150 grams, 25 °C, 5 sec, ASTM D 217, mm/10 |

175 |

250 |

|

3. |

Weight, kg/L |

1.17 |

-- |

|

4. |

Non-volatile, 10 g, 105 to 110 °C, |

75 |

-- |

|

5. |

Ash, by ignition, % |

25 |

45 |

Furnish materials according to the Department’s

Qualified Products List (QPL).

706.11 Resilient and Flexible Gasket Joints. Provide resilient and flexible gasket joints for concrete pipe according to ASTM C 443 (ASTM C 443M).

Furnish materials according to the Department’s Qualified Products List (QPL).

706.12 Resilient and Flexible Joints. Provide resilient and flexible joints for vitrified clay pipe according to ASTM C 425.

Furnish materials according to the Department’s Qualified Products List (QPL).

706.13 Precast Reinforced Concrete Manhole Riser Sections, Flat Slab Tops, Catch Basins and Inlet Tops, and Portable Barriers. Provide precast reinforced concrete manhole riser sections, flat slab tops, catch basins and inlet tops, and portable barriers according to ASTM C 478 (ASTM C 478M), with the following modifications:

1.1 Provide precast catch basin tops where permitted by the plans.

4.1.2.1 Provide cement according to 701, except 701.07.

4.1.2.2 Provide fly ash according to 701.13.

4.1.4 Provide aggregate conforming to the quality requirements of 703.02.

4.1.6 Provide steel according to 709.01, 709.08, 709.10, or 709.12. Provide epoxy coated steel according to 709.00 for the manhole flat slab tops, catch basin tops and inlet tops only.

7.0 In addition, ensure that not more than two holes are cast, drilled, or otherwise neatly made in the shell of each piece of each riser section for the purpose of handling or laying. Taper the holes unless drilled, and before backfilling fill the tapered holes with portland cement mortar or secure the concrete plugs with portland cement mortar. Fill drilled holes with portland cement mortar.

8.2.2 Absorption test does not apply

10.0 Perform inspection at the project site.

11.0 In addition, mark the plant location on each manhole top or barrier section.

Ensure manufacturers providing materials are certified according to Supplement 1073

Ensure that the manufacturer submits design calculations to the Office of Structural Engineering for structures that have a span of 10 feet or greater and are located in the pavement. Ensure the design is based upon section 1000 of the Location and Design Manual, Volume 2. Calculations must contain signatures from two (2) Professional Engineers qualified in structural design

706.14 Flexible Plastic Gaskets. Provide flexible plastic gaskets for concrete pipe according to AASHTO M 198, Type B, with the following modification:

4.3 Flash point and fire point are waived.

Furnish materials according to the Department’s Qualified Products List (QPL).

706.15 Precast Reinforced Concrete Outlets. Provide precast reinforced concrete outlets composed of cement conforming to 701, except 701.07. Provide aggregate conforming to the quality requirements of 703.02. Provide epoxy coated steel reinforcement conforming to 709.00. Do not provide holes for handling or laying. Ensure that the outlet hole are the same size as the outlet pipe. Perform inspection at the project site.

Ensure manufacturers providing materials are certified according to Supplement 1073